Renewable Energy Solutions

Dam Rehabilitation and Reconstruction

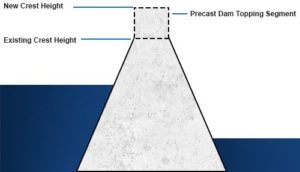

The French Dam Retrofit System can be rapidly deployed and set in sequence to replace a weakened high hazard dam with precast concrete modules that are placed directly downstream of the existing dam. The most important reasons for leaving the existing dam in place is because of the deteriorated condition of the structure and the risk of release of historic contaminated sediments that are trapped behind the existing dam structure.

The EPA believes French Dam Retrofit reduces major risk to the river environment by leaving the existing dam in place and not disturbing the existing contaminated sediment.

After the retrofit is complete, French Development has a system for encapsulating the contaminated sediments in place. This is a major cost savings that contributes to many projects never coming to fruition do to the high cost of removing these highly contaminated sediments. This is a major risk reduction for these highly sensitive contaminated environments in the river systems.

The French Dam Solution can be completed in a matter of weeks verses months or years using cast in place structures.

US Department of Energy Water Power Group and American Society of Civil Engineers (ASCE) funding projections for the next 25 years to upgrade America’s aging and obsolete water infrastructure is estimated to be $640,000,000,000.

Endangered Civil Water Infrastructures

- There are 87,359 dams in the United States, most built mid-20th century

- Over 50% of these structures have already exceeded their designed 50 year lifetime

- “Very heavy precipitation events” in the Northeast have increased nearly 70% over the past 50 years, posing new threats to these structures

- Flooding (overtopping) is the #1 cause of dam failures in this country (70%)

- The American Society of Civil Engineers has given U.S. dams a “D” grade (Poor), and provides estimate of $57B to repair and replace

American Society of Civil Engineers Civil Water Infrastructure Warning

- Applies proven construction methods (precast concrete) in dam reconstruction

- Integrates with hydropower turbine/BOP equipment off-site, assembled in a controlled environment and transport to site for “Plug-and-Play” solution adding value to existing non-powered sites

- 100 years warranty on materials (*)

- U.S. Patents issued, International patents pending

*Subject to manufacturer specification

- Reduced Construction Time (4x), Cost (~60%)

- Risk mitigation (moves primary construction to controlled environment)

- Modular & Customizable – Integrates with wide variety of spillways, abutments, conduits, gates; customizable to fit site

- Quality Control – Manufacturing off-site in controlled environment & shipped to site, allows for standardization of materials/components

This solution will save time, cost and project risk.