Why Dam Construction Needs a Modern Solution

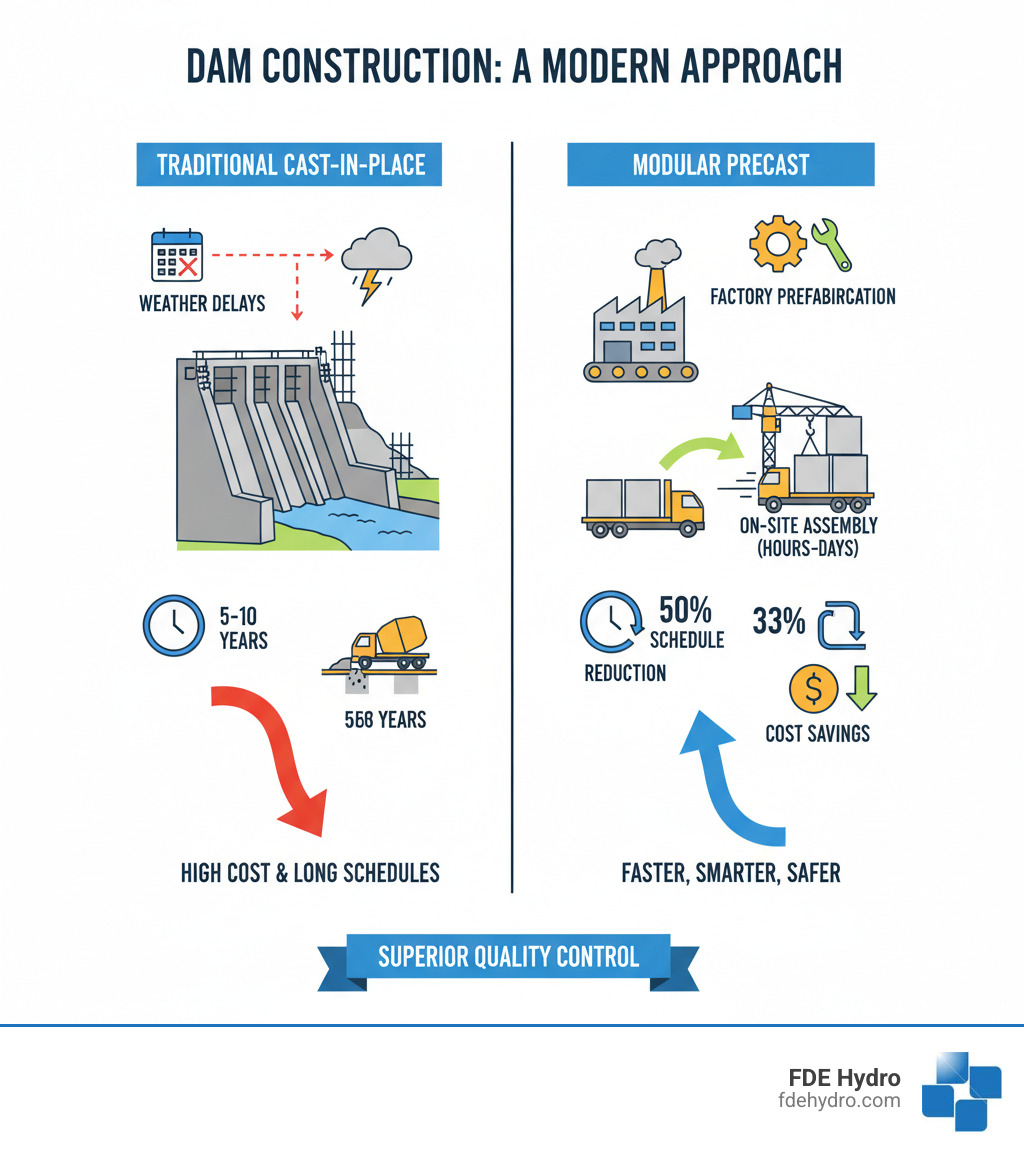

Modular dam construction is revolutionizing water infrastructure by using factory-made components assembled quickly on-site, replacing traditional methods of pouring concrete over months or years. This modern approach cuts construction costs by up to a third and project schedules by half, while enhancing quality control and minimizing environmental impact.

Key differences between traditional and modular dam construction:

| Traditional Cast-in-Place | Modular Precast |

|---|---|

| 40-90% of total project cost is civil construction | Reduces construction costs by 33% or more |

| 5-10+ years for large projects | Construction time cut in half |

| Weather-dependent, high risk of delays | Factory production continues regardless of site weather |

| Quality varies with site conditions | Controlled factory environment ensures consistency |

| Lengthy on-site construction | Modules assembled in hours or days |

| High environmental disruption | Minimal site impact, reduced carbon footprint |

Civil construction is the largest cost component of new hydropower, making up 40-90% of total capital costs. Traditional methods are plagued by risks like schedule overruns from weather, contracting delays, and construction periods that can exceed a decade.

The traditional approach faces mounting challenges:

- The average U.S. dam is 58 years old, exceeding its 50-year design life

- Flooding causes over 70% of dam failures in the United States

- State dam safety budgets average less than $1 million annually

- Only one moderate-sized pumped storage hydropower plant has been built in the U.S. in the past two decades

- Conventional pumped storage facilities can cost up to $5,000 per kilowatt of installed capacity

Meanwhile, aging infrastructure demands urgent attention. South Carolina, for instance, experienced 76 dam failures between 2015 and 2016, requiring approximately $1 billion in federal funding for reconstruction.

Modular construction offers a proven alternative. Manufacturing components in a factory and assembling them on-site delivers predictability, speed, and lower costs. The benefits include less environmental disruption, superior quality control, and resilience to weather delays that stop conventional projects.

A prototype modular dam of six 27,000-pound concrete blocks was assembled in under 3.5 hours, proving the dramatic time savings. For pumped storage hydropower, modular systems could lower costs to $1,500 per kilowatt, making this vital energy storage technology competitive with other renewables.

As Bill French Sr., Founder and CEO of FDE Hydro™, I pioneered our patented “French Dam” technology after five decades in heavy civil construction. Our work, supported by the U.S. Department of Energy, shows how modular precast methods can revolutionize hydropower development.

The Case for Change: Why Traditional Dam Construction is Evolving

Across North America and Europe, we face a quiet crisis: the dams that power our cities and protect our communities are getting old. The average U.S. dam is 58 years old, often exceeding its 50-year design life. We are running on borrowed time with critical infrastructure.

When dams age, the risk of failure increases dramatically. Flooding causes over 70% of dam failures in the United States, turning protective infrastructure into a potential hazard. South Carolina learned this the hard way, experiencing 76 dam failures in 2015 and 2016, which required approximately $1 billion in federal funding to begin reconstruction.

Compounding the problem, state budgets for dam safety average less than $1 million annually—a fraction of what is needed to maintain these aging assets. It’s clear that the old ways of building and maintaining dams are no longer sufficient.

Traditional dam construction simply can’t keep pace. The conventional approach has major drawbacks that make it impractical for modern needs. Physical civil construction alone accounts for 40-90% of total capital costs for new hydropower projects. The timelines are equally daunting, with large projects often taking 5-10 years or more to complete. This long duration exposes projects to significant risks, including weather delays, contracting issues, and complex on-site logistics, making budget overruns almost inevitable.

Furthermore, traditional construction involves years of on-site disruption, including heavy equipment, noise, and dust, which stresses the local ecosystem. Navigating the complex permitting processes, such as the Engineering Guidelines for the Evaluation of Hydropower Projects, can add even more years before work begins.

The result is that new hydropower construction has slowed dramatically. Only one moderate-sized pumped storage hydropower plant has been built in the U.S. in the past two decades, partly because conventional facilities can cost up to $5,000 per kilowatt of installed capacity.

Hydropower remains one of our most valuable renewable energy resources, offering grid stability that other renewables cannot. To open up its full potential, we must fundamentally rethink how we build these structures. We need solutions that drastically cut costs, compress timelines, improve quality, and minimize environmental impact.

This is why modular dam construction represents such a critical shift. It’s a new way of thinking about water infrastructure, and it’s proving that Aging Infrastructure Being Replaced With Next-Generation Civil Solutions is not just possible—it’s practical and available now.

The Core of Innovation: How Modular Dam Construction Works

At FDE Hydro, we’ve reimagined dam construction with our patented “French Dam” technology. The core of our modular dam construction approach is simple: why struggle with unpredictable on-site work when you can manufacture components in a controlled factory and assemble them efficiently where needed?

This method involves building large, precision-engineered components off-site, then transporting them for assembly. This dramatically reduces site disruption and environmental impact while eliminating weather-related delays. It’s the fusion of manufacturing efficiency and civil engineering. Our Modular Construction Techniques page explores this philosophy in greater depth.

Key Components and Materials

Our “French Dam” technology uses components designed for strength and rapid deployment.

Precast concrete modules are the backbone of many systems. These are not typical concrete blocks; they are precision-manufactured with high-strength reinforced concrete (typically 6000 psi) under strict quality controls. Each module is dimensioned for a seamless fit on-site. Explore our designs on the Precast Models page.

For applications like pumped storage hydropower, we often use modular structural steel buttress systems. These prefabricated steel modules offer an excellent strength-to-weight ratio, simplifying transport and assembly while ensuring structural integrity.

Interlocking mechanisms, including bolt linkages and keyways, transform individual modules into a unified, monolithic structure. These connections are designed to withstand enormous hydraulic pressures.

To ensure a watertight barrier, specialized waterstops and sealants are integrated into the joints. We use hydrophilic materials that swell on contact with water, creating an increasingly tight seal that prevents seepage.

Finally, rock anchors secure the entire structure to the bedrock foundation. These large-diameter bolts provide the anchorage needed to resist uplift and sliding forces from the impounded water. For a complete overview, visit our Hydroelectric Dam Components: The Ultimate Guide.

The Assembly Process: From Factory to Foundation

This is where modular dam construction truly excels, enabling assembly in days instead of years.

The process begins with transporting modules on standard flatbed or lowboy trailers, which keeps logistics simple and affordable. While modules are in production, crews handle foundation preparation on-site, ensuring the site is ready for installation. This separation of manufacturing and installation, detailed in our Means and Methods, provides best scheduling flexibility.

The rapid installation is impressive. Using standard cranes, crews lift and position each module onto the prepared foundation. Our prototype dam, with six 27,000-pound blocks, was assembled in less than 3.5 hours, demonstrating the potential for Rapid Installment of Module Precast Civil Infrastructure.

As modules are placed, they are immediately interconnected. Waterstops compress to create a watertight barrier, and in larger structures, post-tensioning systems can be used to improve structural integrity. Final steps include encasing the dam’s heel in concrete and installing liners, drainage systems, spillways, and outlet works.

Perhaps the greatest advantage is resilience to weather. While traditional construction stops for storms or cold, our factory production continues. Only the brief on-site assembly phase requires favorable weather, drastically reducing schedule risks.

Opening Hydropower’s Potential: The Advantages of a Modular Approach

After five decades in heavy civil construction, I founded FDE Hydro to solve the core challenges holding back critical water infrastructure projects. Modular dam construction changes the game by addressing the risks that have long plagued the hydropower industry.

The advantages go beyond simple construction improvements, offering a clear path to reducing risks, ensuring quality, and providing schedule certainty. This approach adds immense Value to our clients and the communities they serve.

Addressing Cost, Time, and Environmental Challenges with modular dam construction

Modular construction directly confronts the persistent challenges of cost, time, and environmental impact. The numbers tell a compelling story.

The cost savings are substantial. With civil works accounting for 40-90% of project costs, our m-Presa™ system can cut dam construction costs by one-third. For pumped storage hydropower, the difference is even more dramatic. While traditional facilities can cost up to $5,000 per kilowatt, modular designs can reduce this to as low as $1,500 per kilowatt. This isn’t a minor improvement—it’s a fundamental shift detailed in our analysis of Why Precast Cost Less.

Time is money. Traditional projects can take a decade or more, but with modular systems, we can reduce construction schedules by half. This means faster returns on investment and communities seeing benefits years earlier. By separating factory production from site preparation, we ensure that weather or other on-site delays have minimal impact on the overall timeline.

Environmental benefits are significant. Shifting fabrication to a factory drastically reduces the on-site construction footprint, meaning less disruption to local ecosystems, reduced pollution, and a smaller carbon footprint. These advantages support our commitment to Sustainable Water Infrastructure.

Quality control is superior in a factory setting. Every module is produced under controlled conditions, ensuring consistent materials, precise measurements, and rigorous inspection. This results in superior structural integrity and long-term durability compared to on-site work vulnerable to weather and other variables.

Enhancing Renewable Energy Integration

The global shift to intermittent renewable energy sources like solar and wind requires robust energy storage to ensure grid stability. Pumped Storage Hydropower (PSH) is the ideal solution—a massive, rechargeable battery for the grid.

PSH facilities pump water to an upper reservoir when electricity is cheap and plentiful, then release it through turbines to generate power during peak demand. It’s a proven technology, accounting for 95% of U.S. energy storage with nearly 80% efficiency, making it a true Guardian of the Grid. Yet, high costs and long construction times have stalled new PSH development.

This is the barrier our modular dam construction solutions break through. By making PSH facilities faster and more affordable to build, we make it practical to support intermittent renewables. Closed-loop systems, built with cost-effective modular dams, can provide massive energy storage with minimal environmental impact. By reducing capital costs to around $1,500 per kilowatt, we make PSH financially competitive, accelerating the adoption of renewable energy. As FDE Hydro’s modular dam design could accelerate the adoption of renewable energy, we are building a more resilient and flexible grid for a sustainable future.

Applications and Considerations for Modular Dam Construction

One of the greatest strengths of modular dam construction is its adaptability. Unlike traditional methods that often require a custom design for every project, modular systems provide a standardized, proven framework that can be custom to specific site needs, geology, and flow requirements. This flexibility opens the door to projects that were previously too expensive or complex.

Our Water Control Infrastructure Guide 2025 explores how these adaptable solutions can meet diverse project requirements across different regions and applications.

Ideal Projects and Use Cases for modular dam construction

Modular construction excels in a wide range of applications:

- New hydroelectric facilities: Especially for low- to moderate-head projects, modular systems dramatically reduce timelines and budgets, making new Hydroelectric Dam Construction more feasible.

- Dam rehabilitation: Instead of a complete teardown, modular components can be used for Dam Rehabilitation Encapsulation, replacing or reinforcing aging sections efficiently and affordably.

- Water control structures: Irrigation weirs, flood control barriers, and municipal water impoundments can all be built faster and more economically using modular Water Control Structures.

- Safety-critical spillways: Modular precast sections can be used to rapidly construct or upgrade Spillways, ensuring they function perfectly during extreme weather to prevent dam overtopping.

- Powerhouses: Even the buildings housing turbines and generators can be built with Modular Powerhouses, getting projects online and generating revenue sooner.

- Emergency dam repairs: When time is critical, prefabricated modules can be transported and deployed quickly to perform emergency repairs, mitigating damage and restoring functionality before a situation worsens.

Limitations and the Path Forward

While modular construction is transformative, it’s important to understand its current considerations.

- Mega-projects: Truly massive dams hundreds of meters high may push the limits of current modular systems, though R&D is constantly expanding these boundaries.

- Logistics: Transporting large components to remote or difficult-to-access sites requires careful planning, but these challenges are manageable.

- Long-term performance data: As a newer approach, modular construction has less long-term field data than traditional dams. However, the use of high-quality materials and superior factory quality control provides strong confidence in durability and longevity.

- Regulatory acceptance: Integrating innovative technologies into established regulatory frameworks takes time. However, regulators are increasingly recognizing the benefits, and successful projects are building the necessary track record for broader acceptance.

Despite these points, the momentum is undeniable. Government support, such as the $1.7 million our “French Dam” technology received from the U.S. Department of Energy, validates the approach and accelerates adoption. The U.S. Department of Energy Hydropower Vision Report Endorses FDE Technology, recognizing its potential to transform the industry.

The future is bright. As the need for resilient infrastructure grows, modular solutions are becoming essential to the Future of Hydropower in North America, Brazil, Europe, and beyond.

Frequently Asked Questions about Modular Dams

How much faster is modular dam construction compared to traditional methods?

Modular construction can cut project schedules in half or more compared to traditional methods, which can take 5-10 years for large projects. The civil works phase, which dominates traditional timelines, is dramatically compressed. Manufacturing happens in a factory while the site is prepared, and on-site assembly is rapid. For example, a prototype dam made of six 27,000-pound concrete blocks was assembled in less than 3.5 hours. This demonstrates the incredible speed possible, allowing critical infrastructure like pumped storage hydropower to come online years sooner.

What are the primary materials used in modular dams?

Modular dam construction uses materials selected for the specific application, focusing on durability and rapid assembly. We have two primary approaches:

- High-strength precast concrete modules: Used in our patented “French Dam” technology, these are precision-engineered components made with 6000 psi reinforced concrete in a controlled factory. This process ensures a level of quality and consistency that is difficult to achieve on-site.

- Prefabricated structural steel buttress systems: Our m-Presa™ design uses lightweight yet incredibly strong steel modules. This approach is particularly advantageous for pumped storage hydropower, as it simplifies transportation and accelerates assembly.

Both material types are designed for efficient transport on standard trailers and are engineered to create robust, long-lasting structures.

Are modular dams as strong and durable as traditionally built dams?

Yes, absolutely. Modular dams are engineered to meet or exceed the same rigorous safety and stability standards as conventional dams. The key difference lies in quality control.

By manufacturing components in a factory, we eliminate variables like weather and inconsistent site conditions that can compromise the quality of traditionally poured concrete. Every module is produced under optimal conditions and undergoes strict inspection before shipping.

Once on-site, these precision components are assembled on a prepared foundation and secured with interlocking mechanisms, bolt linkages, and rock anchors. The result is a monolithic structure that functions as a single, unified barrier, designed to withstand immense forces. We are not cutting corners; we are building smarter with superior quality control, resulting in a durable structure designed for decades of reliable performance.

Conclusion

We are witnessing a transformative moment in civil engineering. Modular dam construction is not just another technique; it’s a fundamental reimagining of how we build critical water and energy infrastructure.

The traditional challenges of crushing costs, long timelines, and environmental disruption have held back hydropower’s potential for too long. By moving manufacturing off-site and assembling structures rapidly on location, we make dam projects predictable, affordable, and dramatically faster. Cutting costs by a third and schedules in half are game-changing improvements.

This innovation is Reinvigorating Hydropower, especially for pumped storage systems essential to a renewable energy grid. It makes sustainable water projects economically viable across North America, Brazil, and Europe.

At FDE Hydro, we are proud to pioneer this future with our patented “French Dam” technology. With support from the U.S. Department of Energy, we have proven these systems work. This paradigm shift is making projects that once seemed impossible a reality.

We invite you to explore how modern solutions are reshaping the future of Dams and to join us in building water infrastructure that is stronger, more efficient, and more sustainable for generations to come.