Why Hydroelectric Dam Design Matters for Our Energy Future

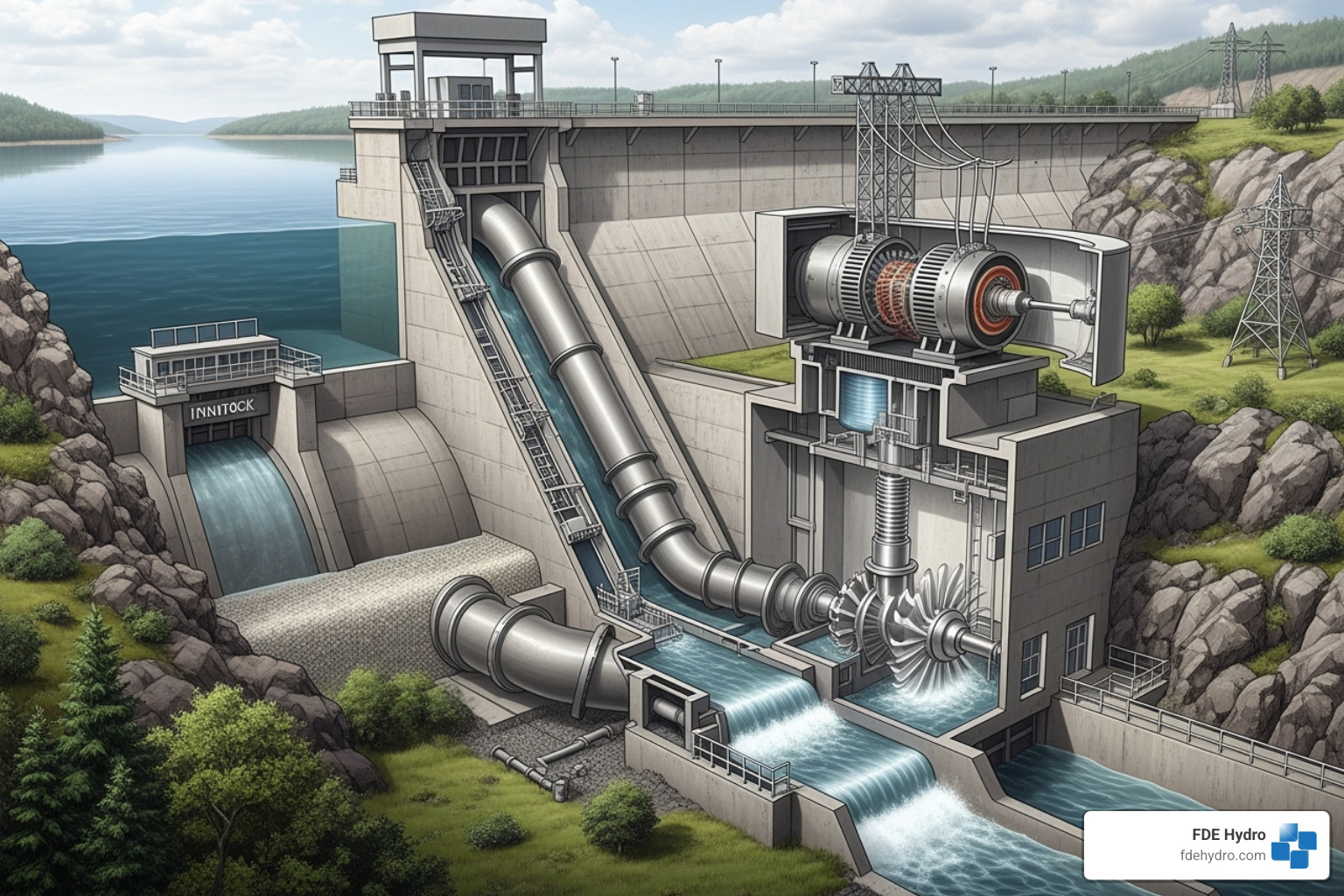

Hydroelectric dam design is the engineering of structures that harness water’s natural flow to generate electricity. It’s a multidisciplinary field—blending civil, mechanical, electrical, and environmental engineering—to create safe, efficient facilities. Key aspects include the dam structure, reservoir, penstocks, turbines, and generators, all designed while accounting for water flow, head height, geology, and seismic risks.

Modern hydropower is a sophisticated blend of engineering and environmental stewardship. Today, hydropower accounts for 27% of total U.S. utility-scale renewable electricity generation and provides 96% of all utility-scale energy storage through pumped storage facilities. With facilities lasting 65-85 years, today’s design decisions shape our energy future for generations.

Nearly 40% of all currently active hydropower licenses in the United States expire in the next 10 years, presenting a critical opportunity to modernize these assets. Modern designs must generate reliable, carbon-free electricity while allowing fish to migrate safely and maintaining the ecological health of river systems.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, where we’ve pioneered modular civil construction solutions for the hydropower industry including the patented “French Dam” technology. After five decades in heavy civil construction, I’ve witnessed how innovative hydroelectric dam design can dramatically reduce project timelines, costs, and environmental impacts.

This guide walks through the complete process of hydroelectric dam design—from fundamental components to the modern innovations making hydropower more efficient and responsible than ever before.

The Blueprint: Core Components and Types of Hydroelectric Dams

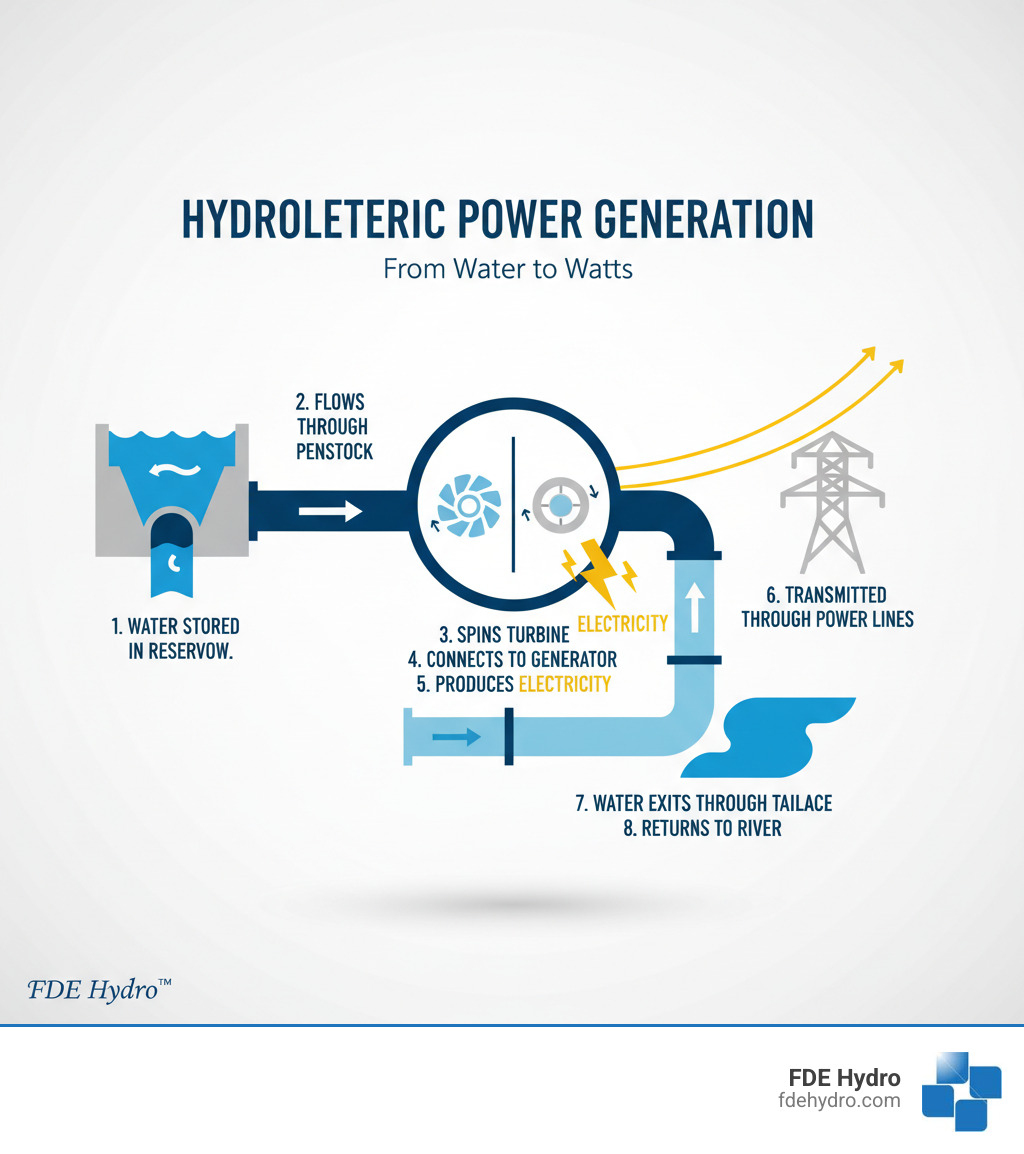

Hydroelectric dam design starts with a simple idea: capturing the energy of flowing water. Water in a high reservoir holds potential energy. As it flows downward through massive pipes, this becomes kinetic energy, which spins turbines. The turbines drive generators, converting mechanical motion into electrical power.

Every hydroelectric facility shares these fundamental components working together.

The dam structure creates the “head,” or elevation difference, and holds back the reservoir, an artificial lake storing water’s potential energy. The intake structure controls water flow into penstocks—large pipes that carry water down to the powerhouse. Inside, turbine-generator units convert the water’s force into electricity. Water then exits via the tailrace back to the river, and transmission lines deliver the power to the grid.

Key Components and Functionality in Hydroelectric Dam Design

The heart of hydroelectric dam design is maximizing energy conversion efficiency. Two factors dominate this equation:

Head height is the vertical distance water falls from the reservoir to the turbine. Greater head means more potential energy.

Water flow rate is the volume of water passing through the turbines. More flow means more kinetic energy. Our work designing Water Control Structures focuses on managing these two variables to maximize energy conversion.

Primary Hydroelectric Technologies

While the physics remain constant, hydroelectric dam design takes three distinct forms:

Impoundment dams are what most people envision: a large dam creates a substantial reservoir, storing vast quantities of water. This provides tremendous operational flexibility to generate electricity when demand peaks. However, creating large reservoirs significantly alters the landscape.

Diversion facilities, or run-of-river plants, take a gentler approach. They channel a portion of the river’s natural flow through turbines with minimal water storage. The environmental footprint is considerably smaller, but they offer limited flexibility, functioning primarily as baseload capacity.

Pumped Storage Hydropower is essentially a giant battery for the electrical grid. During periods of low electricity demand, it pumps water from a lower reservoir to an upper one. When demand surges, that stored water rushes back down through turbines, generating electricity. Pumped Storage Hydropower currently provides 96% of all utility-scale energy storage in the United States, making it indispensable for integrating intermittent sources like solar and wind.

The Human Element: Multidisciplinary Expertise in Hydroelectric Dam Design

No one builds a dam alone. The complexity of hydroelectric dam design demands a team of specialists working in harmony. This collaborative approach spans the entire project lifecycle, as every site presents a unique puzzle of geology, hydrology, and ecological factors that require custom solutions. Our advanced Means and Methods in construction depend entirely on this team-based philosophy.

Essential Engineering Disciplines

The backbone of any project is its core engineering team:

- Civil engineers design the dam structure, spillways, and powerhouse, ensuring structural integrity against immense forces.

- Geotechnical engineers are the foundation specialists. They analyze soil and rock to ensure the ground can support the structure and evaluate seismic stability.

- Mechanical engineers design the machinery, including the turbines, gates, and valves that are custom-engineered for each site’s specific head and flow.

- Electrical engineers design the generators, transformers, and switchyards that convert mechanical rotation into grid-ready electricity.

All these disciplines operate within rigorous frameworks like the Federal Energy Regulatory Commission’s Engineering Guidelines for the Evaluation of Hydropower Projects.

Supporting Expertise

Beyond the core engineers, successful hydroelectric dam design requires other vital experts:

- Environmental scientists assess ecological impacts and develop mitigation strategies like fish passages, which are often critical for regulatory approval.

- Geologists provide a big-picture understanding of the site’s rock formations, fault lines, and long-term stability.

- Construction managers translate complex designs into actionable schedules, managing budgets, timelines, and work crews.

- Economic analysts ensure projects are financially viable through feasibility studies and cost-benefit analyses. Our article on Financing Long-Term Hydropower Requires Mitigating Risks Prior to ROI explores this topic.

- Regulatory compliance specialists steer the complex web of permits and approvals from multiple agencies.

This holistic approach ensures each project is not just technically sound, but also environmentally responsible, economically viable, and built to last for generations.

Balancing Power and Planet: Environmental and Safety by Design

Modern hydroelectric dam design requires balancing the use of nature’s power with protecting the river systems that provide it. It’s a responsibility that shapes every design decision.

Environmental Considerations in Modern Hydroelectric Dam Design

A major focus is mitigating environmental impacts. Traditional turbines can be harmful to fish, but this has sparked remarkable innovation. The development of fish-friendly turbines with blunted, curved blades can achieve greater than 99% safe passage rates for some species—a game-changing breakthrough.

Beyond fish passage, we address a full range of impacts. We incorporate sediment bypass systems to maintain natural flows, design multi-level intakes to regulate water temperature, and use aeration systems to maintain dissolved oxygen levels. These systems for Aquatic Animal and Recreational Passage are fundamental to modern, responsible design.

Critical Safety and Risk Management

Safety is the other non-negotiable pillar of hydroelectric dam design. When holding back millions of gallons of water, there is no room for error.

The spillway is the primary safety feature, designed to safely release floodwaters that exceed the reservoir’s capacity. We design spillways to handle the Probable Maximum Flood (PMF)—the worst-case flood scenario possible for a location. An undersized spillway is a leading cause of catastrophic dam failures.

Structural stability is also paramount. We perform exhaustive analyses to ensure the dam can resist overturning forces from water pressure and sliding forces that push it downstream. We also design drainage and grouting systems to counter uplift pressures from water seeping underneath the structure.

Seismic considerations are crucial, especially in active regions. Dams must be designed to withstand a Maximum Credible Earthquake without catastrophic failure. Finally, every facility has an Emergency Action Plan (EAP) with early warning systems and evacuation plans for downstream communities. This comprehensive approach to safety and environmental responsibility defines modern hydroelectric facilities.

The Future is Now: Modernization and Innovation in Dam Engineering

The world of hydroelectric dam design is undergoing a remarkable change that’s making projects faster, greener, and more efficient. At FDE Hydro™, we’re proud to be part of this Reinvigorating Hydropower movement.

Retrofitting Existing Dams for Power Generation

A huge opportunity lies in retrofitting existing dams. Of the more than 80,000 dams in the U.S., only about 3% generate electricity. Adding hydropower to these non-powered structures could yield an impressive 10,000 MW of energy by 2025. This is where innovation shines. Our modular precast technology is particularly effective for these challenges. We can perform Dam Rehabilitation Encapsulation with minimal disruption, essentially Aging Infrastructure Being Replaced with Next-Generation Civil Solutions.

Integrating Digital Tools: BIM and Digital Twins

The digital revolution has also arrived. Building Information Modeling (BIM) creates a complete 3D digital model, allowing teams to spot problems before they become expensive mistakes. Digital twins go further, creating a live virtual copy of the dam fed by sensor data for predictive maintenance and operational optimization. Unmanned Aerial Systems (UAS)—drones—are now standard tools for rapid and safe inspections.

The Rise of Modular and Run-of-River Designs

Two design trends are also reshaping the industry. Run-of-river designs have a smaller environmental footprint, diverting a portion of a river’s flow through turbines without a massive reservoir.

Modular construction is perhaps the most exciting innovation. At FDE Hydro™, our patented “French Dam” technology uses precast concrete sections manufactured off-site. Manufacturing in a controlled factory environment ensures quality and speed. Sections arrive ready to install, dramatically reducing construction time and on-site risks. Our Modular Powerhouses can be assembled in a fraction of the time, and there are compelling reasons Why Precast Cost Less. These innovations are about building smarter—respecting both natural systems and the urgent need for clean, reliable energy.

Frequently Asked Questions about Hydroelectric Dam Design

Over my five decades in this industry, I’ve answered countless questions about hydroelectric dam design. Here are the most common ones.

What are the main types of hydroelectric dams?

There are three primary types. Impoundment facilities use a large dam to create a reservoir, storing water to generate flexible, on-demand power. Diversion facilities (run-of-river) channel a portion of a river’s flow through turbines with minimal storage, resulting in a smaller environmental footprint but less operational flexibility. Pumped Storage Hydropower acts like a giant battery for the grid. It uses cheap, off-peak power to pump water to an upper reservoir and releases it to generate power during peak demand, providing critical grid stability.

Why is spillway design so critical for dam safety?

Spillways are the safety valve that prevents catastrophic failure during extreme floods. If a reservoir fills faster than turbines can release water, the level can rise and overtop the dam—a leading cause of dam collapse. We design spillways to handle the Probable Maximum Flood (PMF), the worst-case flood scenario imaginable for a location, ensuring the dam’s integrity during extreme weather.

Can existing non-powered dams be converted to produce electricity?

Absolutely, and this is one of the biggest opportunities in renewable energy. The U.S. has over 80,000 dams, but only 3% generate power. Retrofitting these structures is often faster and cheaper than building new dams, with a smaller environmental impact. The engineering can be complex, as you’re often working with aging structures. This is where modern techniques like our modular Dam Rehabilitation Encapsulation are invaluable, breathing new life into Aging Infrastructure Being Replaced with Next-Generation Civil Solutions. Studies suggest this could add 10,000 MW of clean energy capacity by 2025.

Conclusion

The story of hydroelectric dam design is one of human ingenuity, evolving from simple watermills to sophisticated facilities that are cornerstones of our energy grid. The design process is a collaborative effort, balancing immense technical challenges with a critical responsibility to protect natural ecosystems.

Hydropower generates 27% of all renewable electricity in the United States and provides an incredible 96% of our utility-scale energy storage. With lifespans of 65 to 85 years, the design decisions we make today will serve generations.

We are at a pivotal moment, with many licenses expiring and tens of thousands of non-powered dams ready for upgrades. This is an extraordinary opportunity to add clean energy capacity with less environmental disruption.

Innovation is driving this change. Fish-friendly turbines, digital twins, and modular precast construction—which we’ve pioneered at FDE Hydro™ with our patented “French Dam” technology—are making hydropower more sustainable and cost-effective.

Hydropower is not a relic; it’s a dynamic technology essential for our future. It provides the stability and storage that enables the growth of intermittent renewables, acting as the 4 Reasons Why Hydropower is the Guardian of the Grid.

The path forward requires balancing energy needs with ecological stewardship. At FDE Hydro™, we’re committed to advancing modular solutions that make hydroelectric dam design faster, more affordable, and more sustainable.

Ready to explore how modular hydropower technology can work for your project? Visit us to Explore advanced dam solutions and find what’s possible when innovation meets experience.