Why Hydropower Maintenance Matters More Than Ever

Hydro power plant maintenance is the systematic inspection, servicing, and repair of a facility’s components to ensure continuous operation, maximize energy production, and extend asset lifespan to 100+ years. It involves preventive, predictive, and corrective strategies, along with periodic modernization.

With about 70% of all renewable electricity generated globally coming from hydropower, these facilities are critical infrastructure. Good maintenance ensures reliable access to clean energy for decades.

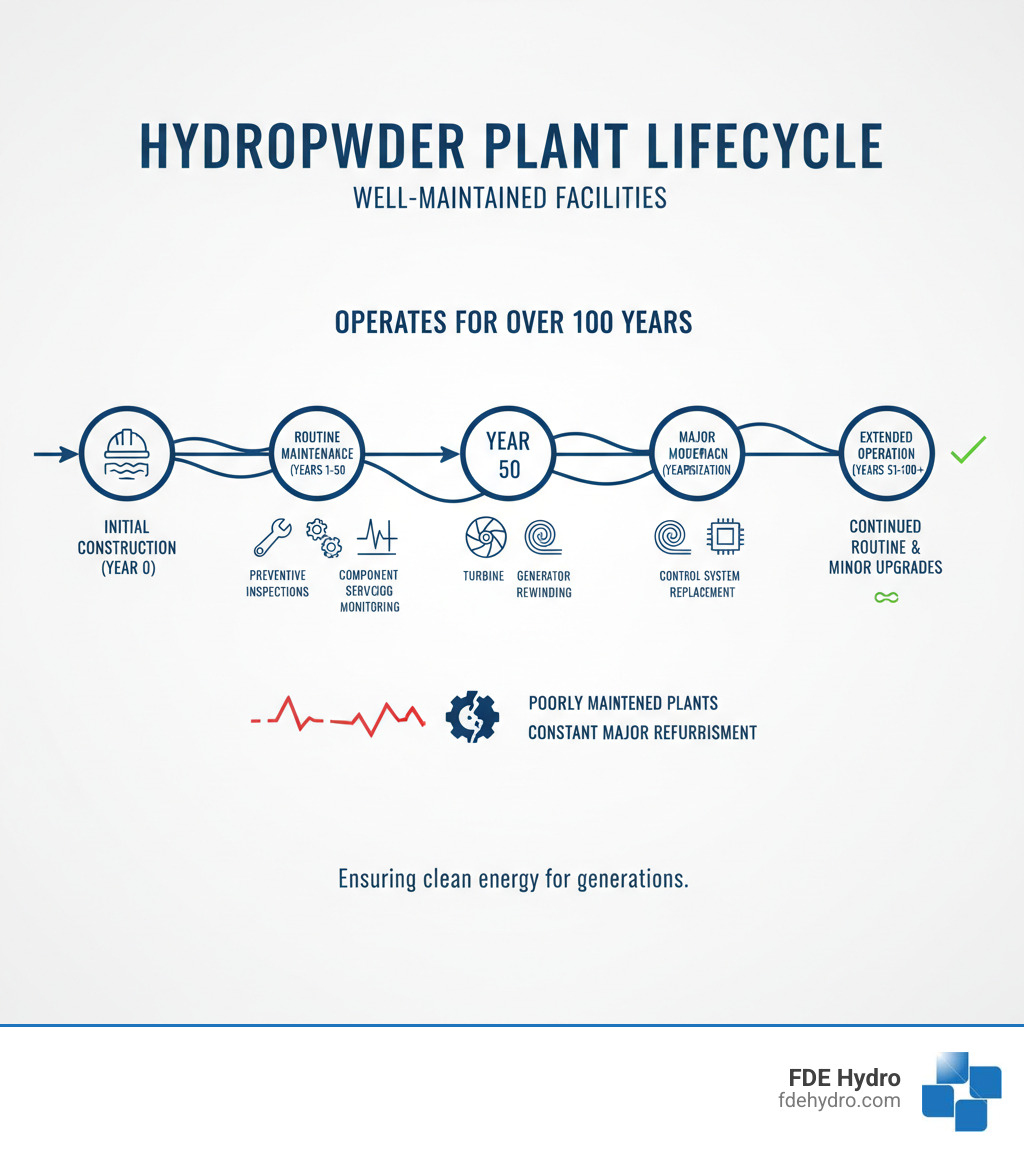

Hydropower facilities can last for more than 100 years when properly maintained. In contrast, neglected plants require constant, costly refurbishment. A total modernization is typically needed every 50 years—a significant investment that can require months of shutdown.

The stakes are high. A sub-optimally operated hydropower system suffers reduced energy production and income. These capital-intensive assets only produce significant returns when maintained to a high standard.

The challenge is growing as infrastructure ages. Over half of the world’s installed hydropower capacity was built before 1990, making these assets prone to failure without proper maintenance. This can lead to high costs and impact grid stability.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, where we focus on delivering modular construction solutions that reduce long-term *hydro power plant maintenance burdens from the start.* My five decades of heavy civil construction experience have given me deep insight into how proper planning and innovative construction can dramatically improve facility longevity and operational efficiency.

The Anatomy of a Hydropower Plant: Key Maintenance Areas

A hydropower plant is a complex system where every component matters. Understanding what needs attention is the first step to mastering hydro power plant maintenance.

Civil Structures and Waterways

These foundational elements face relentless pressure from water and weather.

- Dam Integrity: Regular inspections are essential to catch cracks, erosion, or seepage, preventing catastrophic failures. Our Hydroelectric Dam Components: Ultimate Guide provides a comprehensive overview.

- Penstocks: These massive pipes require internal and external checks for corrosion and cavitation pitting, which can weaken the structure.

- Spillway Gates & Intake Screens: Gates must be tested to ensure they operate during high-flow events. Screens need regular cleaning to prevent debris from damaging downstream equipment.

- Debris Management & Corrosion Protection: Ongoing debris removal and corrosion protection (coatings, cathodic systems) are critical for longevity, as emphasized in industry guides like the Bureau of Reclamation’s FIST manuals.

Electromechanical Equipment

This is where water’s energy becomes electricity and where maintenance directly impacts revenue.

- Turbines & Generators: Turbines face immense force and require regular cavitation repair and balancing. Generators, which convert rotation into current, need specialized servicing like rewinding and re-insulation.

- Transformers & Switchgear: Transformers step up voltage for transmission and require oil analysis and cooling system checks. Switchgear, the plant’s electrical safety system, needs regular testing and calibration.

- Control Systems & Auxiliary Motors: The plant’s “brain”—PLCs and SCADA systems—needs software updates and calibration. Smaller auxiliary motors that power pumps and valves are also critical; their failure can shut down main units.

Supporting Systems

A network of support systems is essential for safe and efficient operation.

- Hydraulic, Cooling, and Lubrication Systems: Hydraulic units power gates and valves. Cooling systems dissipate heat from generators and transformers. Lubrication systems prevent friction and wear on all rotating machinery. All require regular fluid checks, filter changes, and inspections.

- Fire Protection & SCADA: Fire detection and suppression systems must be tested to protect against electrical and oil-related risks. SCADA systems enable remote monitoring and require network security and sensor calibration.

- Load-Handling Equipment: Overhead cranes are vital for major maintenance tasks. Their failure can cause significant delays, so rigorous inspection of their structural and mechanical components is crucial.

Strategic Approaches to Hydro Power Plant Maintenance

Effective hydro power plant maintenance uses a toolbox of strategies. The smartest operators know when to use each tool.

Preventive Maintenance

Preventive maintenance is the bedrock of a smooth-running plant. The philosophy is simple: perform scheduled inspections, routine lubrication, and component replacements based on lifespan to catch problems before they cause failures. Industry playbooks like the Bureau of Reclamation’s FIST manuals provide detailed frameworks for this methodical work.

A typical annual preventive checklist includes:

- Turbine, gearbox, and generator functional checks and lubrication

- Hydraulic system checks (fluid levels, filters, leaks)

- Sensor and controller calibration

- Inspection of intake areas and pipelines

- Electrical inspection and testing

- Testing hydraulic accumulators

- Cleaning automated intake screens

Predictive Maintenance (PdM)

Predictive maintenance uses technology to forecast failures. Instead of just following a schedule, operators listen to what the equipment is telling them through condition monitoring.

- Condition Monitoring: Technologies like vibration analysis, thermal imaging, and oil analysis assess equipment health in real-time.

- Early Issue Identification: Digital Asset Performance Management (APM) systems analyze this data to identify issues before they become emergencies. This allows repairs to be scheduled precisely when needed, avoiding both premature parts replacement and catastrophic failures. This proactive approach is central to the future of hydropower, ensuring greater reliability.

Corrective and Emergency Maintenance

Even with the best strategies, unexpected failures occur. Corrective maintenance is about responding quickly and effectively.

- Unplanned Outage Response: When a critical component fails, speed is essential. Rapid access to emergency response teams minimizes costly downtime.

- Failure Analysis: After a failure, a root cause investigation is crucial to understand why it broke and prevent a recurrence.

- Spare Parts Management: A well-managed inventory of genuine, high-quality spare parts is an insurance policy against extended downtime, ensuring replacements are on hand when needed.

The High Stakes of Maintenance: Benefits, Costs, and Challenges

Investing in robust hydro power plant maintenance is arguably the most important strategic decision for a facility, impacting profitability, safety, and long-term sustainability.

Key Benefits of a Robust Maintenance Program

Comprehensive maintenance secures the future of your operation with substantial, measurable advantages.

- Guaranteed Availability: Consistent maintenance reduces unexpected equipment failures, keeping plants online and generating power. This reliability is why hydropower is known as the guardian of the grid.

- Extended Lifespan: Well-maintained facilities can operate for over 100 years, a proven track record confirmed by the World Bank.

- Increased Energy Production: Efficiently running equipment converts more water energy into electricity, maintaining consistently high production levels.

- Improved Safety: A well-maintained plant is a safer workplace, reducing accident risks for personnel and the community.

- Predictable Costs: Proactive maintenance allows for planned, budgeted expenses rather than costly emergency repairs.

For more on hydropower’s reliability, explore the Benefits of Hydropower Plant.

Common Challenges and How to Address Them

Hydro power plant maintenance comes with real challenges.

- Aging Infrastructure: With over half the world’s hydro capacity built before 1990, older facilities require thoughtful, long-term modernization plans.

- Modernization & Shutdowns: Major overhauls, typically needed every 50 years, are complex and require four to six months of downtime. This lost revenue can be minimized by scheduling work during low-production periods.

- Remote Sites & Skilled Labor: Many plants are in remote locations, complicating logistics. Furthermore, securing skilled technicians with specialized knowledge is increasingly difficult, making partnerships with experienced service providers essential.

Understanding the Costs of Hydro Power Plant Maintenance

The true cost of maintenance includes direct expenses and the hidden costs of deferring it.

| Cost Category | Routine O&M | Major Overhaul | Equipment Failure |

|---|---|---|---|

| Direct Expenses | Regular inspections, parts replacement, lubrication, minor repairs—budgeted and predictable | Planned equipment upgrades, turbine refurbishment, generator rewinding—scheduled during low-revenue periods | Emergency repairs, expedited shipping, overtime labor—unpredictable and premium-priced |

| Lost Revenue | Minimal—brief scheduled outages during low-demand periods | Moderate—4-6 months shutdown, but planned to minimize impact | Severe—unexpected outage duration unknown, occurring at worst possible times |

| Long-term Impact | Extends asset life to 100+ years, maintains peak efficiency | Modernizes facility for another 50 years of operation, may increase capacity 1-2% | Cascading failures, shortened equipment lifespan, reputation damage with grid operators |

| Typical Cost Range | 2-3% of annual revenue (industry standard) | $50-500 million depending on facility size | 3-10x higher than planned maintenance, plus opportunity costs |

The numbers are clear: routine maintenance is a predictable expense, while emergency repairs can cost up to ten times more, not including lost revenue. The long-term ROI overwhelmingly favors proactive maintenance. At FDE Hydro, our modular precast technology builds durability into the structure from day one, reducing future maintenance burdens and supporting the century-plus lifespan that makes hydropower so valuable.

The Digital Frontier: Enhancing Maintenance with Technology

The world of hydro power plant maintenance is shifting from a reactive approach to intelligent, data-driven management that anticipates problems before they happen.

The Role of Asset Performance Management (APM)

APM solutions act as the nervous system of a hydropower plant, integrating digital monitoring with advanced analytics for a real-time view of every critical component. Sensors continuously collect data, which is then processed by APM platforms to identify patterns and anomalies.

The most impressive feature is AI-powered predictions. Machine learning algorithms analyze historical and current data to forecast potential equipment failures. These advanced APM solutions are designed to identify issues early, providing warnings that allow maintenance teams to act before a small problem becomes a major crisis. This early fault detection transforms maintenance into a planned, strategic operation and helps optimize performance across the board.

Innovations in Maintenance Technology

The technological revolution extends beyond software to physical inspections and repairs, making the work safer and faster.

- Drones and Robotic Crawlers: Drones are invaluable for visual inspections of large structures like dams and spillways, capturing high-resolution imagery without putting personnel at risk. Inside penstocks, robotic crawlers can perform detailed inspections and minor repairs without needing to dewater the pipe.

- Advanced Sensors: Miniaturized wireless sensors provide increasingly granular data on vibration, temperature, and pressure, feeding APM systems to create a detailed picture of equipment health.

- Eco-Friendly Cleaning: Innovative techniques like Dry Ice Blast Cleaning use frozen carbon dioxide pellets to clean generators and other equipment. This method leaves no residue, doesn’t damage delicate components, and is non-toxic.

The pace of innovation continues, with institutions like the National Renewable Energy Laboratory pushing the boundaries of hydropower technology. Their research helps ensure the future of hydropower will be even more reliable and sustainable. At FDE Hydro, we believe modern construction methods reduce maintenance from day one, helping facilities achieve a 100-year lifespan with maximum performance.

Compliance and Best Practices: Safety and Environmental Stewardship

Effective hydro power plant maintenance is about more than keeping turbines spinning; it’s about working safely and protecting the environment. As stewards of both energy and natural resources, we prioritize worker safety and minimal ecological impact.

Regulatory Standards and Safety Protocols

Hydropower plants can be dangerous, involving high voltage, massive machinery, and immense water pressure. Safety is woven into every aspect of our maintenance operations.

- Key Standards: In the U.S., OSHA standards form the backbone of safety programs. Guidelines from the U.S. Army Corps of Engineers (USACE) and the Bureau of Reclamation (FIST manuals) provide detailed, practical safety criteria for hydropower facilities.

- Energy Control & Arc Flash: Robust lockout/tagout programs are fundamental to prevent accidental equipment startup during maintenance. Arc flash assessments are also critical to identify electrical hazards and establish safe work practices.

- Fire Prevention: Comprehensive firefighting and prevention strategies, including detection and suppression systems, are essential to protect personnel and assets from electrical and oil-related fire risks.

For more on the infrastructure supporting these systems, see our Water Control Infrastructure Guide 2025.

Environmental Considerations and Best Practices

Our commitment to clean energy requires that our maintenance activities protect surrounding ecosystems.

- Eco-Friendly Materials: We use Environmentally Acceptable Lubricants (EALs) in areas with any risk of discharge into water. Unlike petroleum-based oils, EALs biodegrade rapidly and pose minimal environmental risk.

- Water Quality & Fish Passage: We manage dissolved oxygen (DO) levels to protect aquatic life downstream, sometimes using auto-venting turbine technology. We also ensure fish passage systems like ladders and bypass channels remain clear and functional.

- Spill Prevention & Impact Minimization: Strict oil spill prevention protocols are non-negotiable. During major repairs, we employ measures like waste management and erosion control to minimize ecological impact, often timing work to avoid sensitive periods for local wildlife.

At FDE Hydro, our modular precast technology also minimizes environmental disruption during construction and future retrofits, a benefit that extends throughout the facility’s long lifespan.

Conclusion: Securing the Future of Hydropower

The story of hydro power plant maintenance is one of continuous investment in the future of clean energy. A well-maintained hydropower facility is a legacy asset, capable of generating clean electricity for 100 years or more. This remarkable longevity doesn’t happen by accident; it requires dedication.

Successful maintenance relies on a strategic blend of preventive, predictive, and corrective approaches. Modern tools like Asset Performance Management systems, drones, and AI-powered analytics make this work more effective than ever. However, technology alone is not enough. Safety for technicians and communities must always come first, and environmental stewardship is a core responsibility. Using Environmentally Acceptable Lubricants and maintaining fish passages are not just regulations—they are commitments to being good neighbors to the natural world.

Here at FDE Hydro™, we know that innovation in construction sets the stage for easier, more cost-effective maintenance. Our modular precast technology creates durable structures that reduce the maintenance burden for decades. As explored in our article on Financing Long-Term Hydropower Requires Mitigating Risks Prior to ROI, considering the full lifecycle from day one is key to economic viability.

The future of hydropower is bright. With proper maintenance, strategic modernization, and continued innovation, these remarkable facilities will continue to be a reliable, flexible, and clean cornerstone of our energy supply for generations to come. We’re not just maintaining equipment; we’re securing a cleaner, more sustainable energy future.