Why Concrete Construction Methods Matter for Modern Infrastructure

Precast concrete advantages are reshaping how we approach large-scale infrastructure projects. In construction, concrete is a vital building material—but how and where it’s produced makes all the difference. The choice between precast, modular, and cast-in-place concrete directly impacts project timelines, costs, quality, and long-term performance.

Key Precast Concrete Advantages at a Glance:

- Superior Quality Control – Factory manufacturing ensures consistent mix design, precise curing, and minimal defects

- Faster Construction – Off-site fabrication allows parallel site work and just-in-time delivery, reducing timelines by months

- Lower Total Costs – Reduced on-site labor, less weather delay, and efficient material use cut overall project expenses

- Improved Durability – Controlled curing produces high-density concrete resistant to weather, fire, and corrosion

- Design Flexibility – Custom molds enable complex shapes, textures, and finishes for both structural and architectural applications

- Improved Safety – Fewer workers on-site and controlled factory conditions reduce workplace accidents

- Sustainability – Minimized waste, material recyclability, and energy efficiency support green building goals

Every construction project—whether it’s a hydroelectric dam, bridge, or commercial building—faces the same challenges: tight budgets, demanding schedules, and the need for structures that last generations. Traditional cast-in-place concrete, mixed and poured on-site, has served the industry for decades. But it’s vulnerable to weather delays, quality variations, and extensive labor requirements.

Precast concrete takes a different approach. Components are manufactured in controlled factory environments, then transported to the construction site for rapid assembly. This industrialized method delivers consistent quality while dramatically compressing construction schedules.

Modular construction extends these benefits even further, treating entire building sections or infrastructure components as prefabricated units. For water infrastructure and hydropower projects, this means changing months of on-site work into days of assembly.

The controlled environment where precast concrete is manufactured is key. Factory conditions eliminate weather as a variable. Quality inspections happen at every stage. Curing processes are optimized. The result? Concrete that’s stronger, more durable, and more reliable than most site-cast alternatives.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, where we’ve revolutionized hydropower construction through modular precast solutions including the patented French Dam. My five decades in heavy civil construction, including landmark projects like the I-93 Fast14 utilizing modular precast bridge construction, have shown me how precast concrete advantages deliver changeal value for large-scale infrastructure.

What is Precast Concrete and How Does It Compare?

At its heart, precast concrete is simply concrete that is cast somewhere other than where it will ultimately be used. Think of it as a carefully crafted component, manufactured in a dedicated factory, or “precast plant,” before being shipped to the construction site. This off-site manufacturing process allows for unparalleled control over every aspect of production, from the mix design to the curing conditions.

In contrast, traditional cast-in-place concrete is mixed and poured directly on the job site. While this method offers flexibility for unique, one-off designs, it’s inherently exposed to the whims of weather, site conditions, and the availability of skilled labor. This can lead to variability in quality and significant delays.

A specialized form of precast concrete, prestressed concrete, further improves its capabilities. Here, high-strength steel strands are incorporated and put under tension before the concrete is cast and cured. Once the concrete hardens and the tension is released, the concrete becomes compressed, significantly increasing its load-carrying capacity, allowing for greater spans, and reducing the potential for cracks. This makes it an incredibly robust option for demanding structural applications.

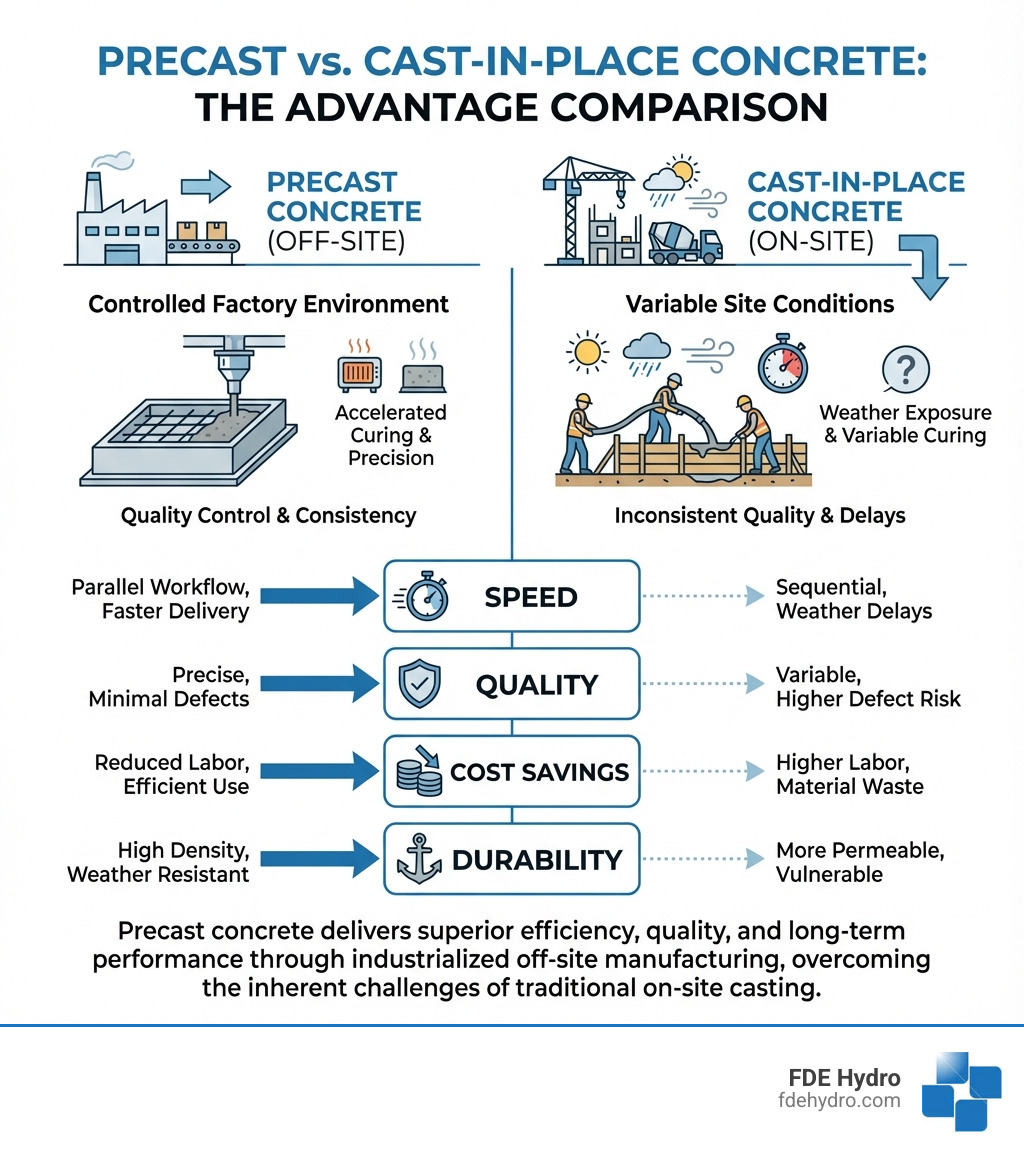

To illustrate the fundamental differences and why precast concrete advantages often tip the scales, let’s look at a quick comparison:

| Feature | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Quality Control | Superior, factory-controlled conditions | Variable, dependent on on-site conditions |

| Construction Speed | Faster assembly, simultaneous site work | Slower, sequential, requires on-site curing |

| Weather Dependency | Minimal impact on production, unaffected on-site | Highly susceptible to weather delays |

| Site Disruption | Reduced, less equipment and labor on-site | Higher, more equipment, materials, and labor on-site |

| Labor Requirements | Less on-site skilled labor needed | More on-site skilled labor for forming and pouring |

The modern construction landscape, particularly in North America, Brazil, and Europe where we operate, increasingly favors the efficiency and reliability that precast methods offer. This shift is driving innovation across the entire precast industry. For more detailed insights into this versatile material, you can explore comprehensive resources like About Precast.

The Core Precast Concrete Advantages: Quality, Speed, and Cost

When we talk about the transformative power of precast concrete, we’re really honing in on three pillars: unparalleled quality, accelerated timelines, and significant cost savings. This isn’t just about building faster; it’s about building smarter, with industrialized production leading to greater efficiency and reliability. The sum of these benefits is why precast offers superior value in modern construction.

Superior Quality and Durability from Controlled Manufacturing

One of the most compelling precast concrete advantages stems directly from its manufacturing environment. Imagine baking a cake: would you prefer to do it in a state-of-the-art, climate-controlled kitchen, or outdoors in unpredictable weather? It’s a bit like that with concrete.

In a factory-controlled environment, every variable is carefully managed. This means:

- Consistent Mix Design: We ensure the precise proportions of cement, water, aggregates, and admixtures every single time. This eliminates the guesswork and variability inherent in on-site mixing, leading to a consistently strong and uniform product.

- Precise Curing Process: Curing is crucial for concrete strength. In our plants, we control temperature and humidity, often employing accelerated curing methods. This ensures the concrete reaches its optimal strength faster and more reliably than traditional site-cured concrete. This controlled curing environment, coupled with an optimized water-to-cement ratio, significantly reduces the likelihood of cracking.

- High-Density Concrete: The rigorous control over mixing, placement, and consolidation (often using advanced vibration techniques) results in high-density concrete. This dense structure is less porous, making it incredibly resistant to acid attack, corrosion, and impact.

- Reduced Cracking: Because precast concrete is cured under ideal conditions, it’s far less prone to the shrinkage and thermal cracking that can plague site-poured concrete exposed to fluctuating outdoor conditions.

- A1 Fire Rating: Precast concrete is inherently non-combustible. It doesn’t catch fire, give off toxic fumes, or add fuel to a blaze, earning it a top A1 fire rating. This provides superior fire resistance, enhancing safety for occupants and protecting structural integrity.

- Excellent Weather and Corrosion Resistance: Its high density and controlled composition make precast concrete incredibly durable against the elements. It stands up to freeze-thaw cycles, moisture, and corrosive agents, performing exceptionally well even in harsh marine or coastal environments.

- Long Service Life: All these factors—superior materials, precise manufacturing, and inherent resilience—contribute to an exceptionally long service life. Precast concrete structures are often designed to last 100 years or more with minimal maintenance.

Accelerated Construction Timelines and Reduced Project Costs

Time is money in construction, and this is where precast concrete advantages truly shine. We’ve all seen projects stalled by unexpected rain, freezing temperatures, or simply waiting for concrete to cure. Precast largely sidesteps these issues.

Here’s how we accelerate timelines and reduce costs:

- Off-site Fabrication: Components are manufactured in our plants while site preparation, foundation work, and other parallel tasks are completed concurrently. This means no wasted time waiting for one phase to finish before the next can begin. It’s like building with high-precision LEGOs!

- Just-in-Time Delivery: Finished components are delivered to the site precisely when needed for erection. This minimizes on-site storage requirements and streamlines logistics. Our focus on rapid installment of module precast civil infrastructure exemplifies this efficiency.

- Reduced On-site Labor: A significant portion of the work is shifted from the busy, often cramped, construction site to the controlled factory environment. This means fewer workers are needed on-site, which not only reduces labor costs but also helps mitigate skilled labor shortages.

- Less Site Congestion: With fewer materials, equipment, and personnel on-site, the construction area is cleaner, more organized, and easier to manage. This leads to smoother operations and fewer logistical headaches.

- Minimal Weather Delays: Since manufacturing happens indoors, production isn’t halted by rain, snow, or extreme heat. On-site, the erection of precast components is also far less susceptible to weather, unlike pouring and curing traditional concrete. An unexpected downpour might stop an on-site pour, but it won’t stop a crane from lifting precast slabs into place.

- Earlier Project Completion: The combined effect of parallel workflows, faster assembly, and fewer delays means projects are completed sooner. This can lead to earlier occupancy, quicker return on investment, and significant savings on project financing.

The efficiency and predictability of precast construction translate directly into cost savings. This is why precast costs less in the long run, making it an economically sound choice for diverse projects across the United States, Canada, Brazil, and Europe.

Design Versatility and Performance in Demanding Environments

One of the often-underestimated precast concrete advantages is its incredible adaptability. It’s not just a workhorse material; it’s a chameleon, capable of changing into an almost limitless array of aesthetic forms and performing robustly in the most challenging conditions. This makes it ideal for everything from architectural masterpieces to high-performance infrastructure. To understand the possibilities, one only needs to look at the diverse range of precast models available.

Opening up Aesthetic and Structural Flexibility

Precast concrete offers designers an expansive palette to work with, limited only by imagination. We can mold concrete into virtually any shape, size, or form, bringing architectural visions to life with precision and consistency.

- Custom Molds and Complex Shapes: Our controlled factory setting allows for the creation of intricate custom molds, enabling us to cast complex shapes and detailed designs that would be difficult, if not impossible, to achieve with on-site pouring. From graceful curves to sharp angles, precast delivers.

- Variety of Sizes: Whether it’s a massive bridge beam spanning a river or a delicate architectural facade panel, precast components can be custom to meet specific project requirements with a wide range of weights and thicknesses.

- Architectural Finishes, Textures, and Integral Colors: Precast concrete isn’t just gray! We can incorporate a vast array of architectural finishes, from smooth polished surfaces to exposed aggregate, ribbed, or sandblasted textures. Integral colors, pigments mixed directly into the concrete, allow for a permanent and consistent hue throughout the material, offering a rich aesthetic without the need for additional coatings. This means we can deliver building exteriors that are both beautiful and durable.

- Structural Components and Heavy Load-Bearing Capacity: Beyond aesthetics, precast excels structurally. Our components, especially prestressed elements, can achieve exceptional load-bearing capacity. This allows for long, clear spans and fewer internal columns, offering greater flexibility in interior layouts for buildings and robust support for heavy infrastructure. Prestressed panels, for instance, can handle loads exceeding 100,000 pounds, with even higher capacities achievable through specialized design and reinforcement.

High-Performance Resilience: A Key Precast Concrete Advantage

When it comes to enduring the test of time and resisting environmental stressors, precast concrete is like a superhero for your building. Its inherent properties make it incredibly resilient, making it a preferred choice for structures that need to withstand the toughest conditions.

- Superior Fire Resistance: As an A1 fire-rated material, precast concrete is non-combustible. It won’t ignite, doesn’t spread flames, and won’t release toxic fumes during a fire. This provides crucial passive fire protection, giving occupants more time to evacuate and helping to preserve the structural integrity of the building.

- Excellent Noise Reduction and Sound Insulation: The high density of precast concrete makes it an outstanding sound barrier. It effectively blocks out external noise and reduces sound transmission between rooms, making it ideal for residential complexes, hotels, schools, and commercial buildings where acoustic comfort is paramount. Think of how quiet a concrete basement can be!

- Moisture and Rot Resistance: Unlike organic building materials, precast concrete is impervious to moisture-related issues. It won’t rot, mold, or mildew, even in damp environments like basements or water control structures.

- Pest Resistance: Termites, rodents, and other pests can’t chew through concrete, making precast structures naturally resistant to infestations and reducing the need for chemical treatments.

- Ideal for Harsh Environments: From the corrosive salt air of coastal regions to the extreme temperature fluctuations of inland climates, precast concrete performs exceptionally. Its inherent durability makes it a reliable choice for infrastructure projects that face constant exposure to aggressive elements.

- Multi-Hazard Resilience: These combined properties contribute to precast concrete’s multi-hazard resilience. It stands strong against wind, seismic activity, fire, and flood, providing long-term safety and security for buildings and infrastructure. This focus on endurance is critical for modern construction, as highlighted in discussions around innovation and resilience with precast concrete.

The Future is Modular: Safety and Sustainability in Precast Construction

As we look towards the future of construction, modern methods are increasingly prioritizing environmental responsibility and worker safety. The integration of modular and precast technologies represents a significant leap forward in achieving these goals, especially for large-scale infrastructure projects in the United States, Canada, Brazil, and Europe. Our work at FDE Hydro, particularly with modular precast solutions for water control systems, exemplifies this commitment.

Building a Greener Future with One of the Top Precast Concrete Advantages

Sustainability is no longer an option; it’s a necessity. Precast concrete offers a robust pathway to greener construction practices throughout a project’s lifecycle.

- Reduced On-site Waste: Manufacturing in a controlled factory environment drastically minimizes waste. Scraps, excess concrete, and other materials can often be recycled or reused within the plant, leading to far less debris heading to landfills from the construction site.

- Material Efficiency: The precision of factory production ensures that materials are used efficiently, reducing over-ordering and cutting down on waste. This meticulous approach contributes to a lower overall carbon footprint for the project.

- Recyclability of Concrete: Concrete is a natural building material, and at the end of its exceptionally long service life, it’s almost entirely recyclable. Up to 95% of concrete and its reinforcement can be crushed and reused as aggregate in new concrete mixes or as fill material, closing the loop on construction waste.

- Thermal Mass for Energy Savings: Precast concrete’s inherent thermal mass allows it to absorb and store heat, then release it slowly. This property helps regulate indoor temperatures, reducing the demand for heating and cooling. This passive energy efficiency can lead to significant long-term energy savings for buildings and contribute to a lower operational carbon footprint. Its excellent thermal insulation properties also help in limiting energy use.

- LEED Certification Points: Due to its durability, recyclability, energy efficiency, and local sourcing potential, precast concrete products can contribute significantly to achieving LEED (Leadership in Energy and Environmental Design) certification points. Some projects have even seen up to 26 LEED points attributed to the use of precast concrete. This makes it an excellent choice for sustainable water infrastructure projects. The overall precast concrete’s sustainability is a key factor in its growing adoption.

Enhancing Site Safety and Addressing Challenges

Safety is paramount on any construction site. By shifting a large portion of the work off-site, precast concrete fundamentally changes the safety profile of a project, significantly reducing risks for workers.

- Fewer On-site Workers: With components manufactured in a factory, fewer personnel are required on the actual construction site. This directly translates to less congestion, fewer opportunities for accidents, and a generally safer working environment.

- Reduced Workplace Accidents: Factory environments are inherently more controlled, predictable, and ergonomic than dynamic construction sites. Workers operate in stable conditions, often with specialized machinery designed for safety, leading to a substantial reduction in workplace accidents compared to traditional on-site methods.

- Controlled Factory Conditions: Fabrication happens at ground level, eliminating many of the risks associated with working at heights, exposure to severe weather, and uneven terrain. This proactive approach to safety is a major precast concrete advantage.

While precast concrete offers undeniable safety benefits, we also acknowledge and manage its unique challenges:

- Transportation Logistics: Precast components, especially large ones, can be heavy and require careful planning for transport from the plant to the job site. This involves specialized heavy haulage and detailed route planning to ensure safe and timely delivery.

- Heavy Lifting Equipment: Once on-site, the installation of precast elements requires robust lifting equipment, such as tower cranes or mobile cranes. While this equipment is crucial, its use is concentrated on the assembly phase, not continuous pouring and framing.

- Connection Detailing: Ensuring strong and precise connections between precast elements is critical for structural integrity. This requires careful design and installation, but advancements in connection technology continue to simplify and strengthen these interfaces.

These challenges are well-understood and carefully managed within the industry. Through careful planning, advanced engineering, and the use of specialized equipment, the benefits of precast concrete, including its safety advantages, far outweigh these logistical considerations. This systematic approach aligns perfectly with modern modular construction techniques that prioritize efficiency and safety.

Frequently Asked Questions about Precast Concrete

We understand that adopting new construction methods can bring up questions. Here are some of the most common inquiries we receive about precast concrete.

Are precast concrete walls load-bearing?

Absolutely! Precast concrete walls and columns are specifically engineered to be load-bearing. In fact, many precast systems are designed to form the primary structural system of a building. Prestressed panels, for instance, are renowned for their immense strength and can handle loads exceeding 100,000 pounds. With appropriate reinforcement and design, even higher capacities can be achieved, making them ideal for everything from multi-story buildings and parking structures to large-scale Water Control Structures that bear the immense forces of water.

Is precast concrete more expensive than traditional concrete?

This is a common misconception! While the initial unit cost of a precast component might sometimes appear higher than raw materials for cast-in-place concrete, the overall project cost often ends up being lower. This is because precast concrete advantages drive significant savings in other areas. We see reductions in labor costs due to fewer on-site workers and faster assembly. There are fewer costly weather delays, and the accelerated construction schedule means earlier project completion and reduced financing costs. When you factor in the long-term durability and minimal maintenance requirements, precast concrete often provides a superior return on investment. You can find more on why precast costs less by exploring our detailed analysis.

How is precast concrete used in large infrastructure like dams?

Precast concrete is revolutionizing the construction and retrofitting of large infrastructure projects, particularly in the hydropower sector, where we at FDE Hydro are at the forefront. For projects like dams, precast allows for highly efficient modular construction. Instead of pouring massive amounts of concrete on-site in challenging conditions, individual components—such as sluice gates, spillway sections, or structural elements—are manufactured with extreme precision in our controlled factory environments. These modules are then transported to the site and rapidly assembled, drastically reducing construction time and costs. This modular approach is a core principle of innovative Hydroelectric Dam Construction methods, allowing for faster deployment, higher quality, and reduced environmental impact on critical water infrastructure projects across our operational regions.

Conclusion

As we’ve explored, the precast concrete advantages are numerous and impactful, making it a superior choice for modern construction. From the inherent quality and durability born from controlled factory environments to the accelerated timelines and significant cost savings, precast concrete offers a compelling value proposition. Its versatility in design, exceptional resilience against environmental stressors, and contributions to both site safety and environmental sustainability further solidify its position as a leading building material.

At FDE Hydro, we’ve harnessed these benefits to revolutionize hydropower construction. Our innovative use of modular precast technology, including the patented French Dam, demonstrates how these advantages translate into tangible results—significantly reducing construction costs and time for hydroelectric dams and water control systems across North America, Brazil, and Europe.

By embracing precast concrete, we’re not just building structures; we’re building a more efficient, sustainable, and resilient future. We invite you to learn more about how modular precast is transforming the hydropower industry and find the difference it can make for your next project.