Why Modern Water Control Systems Matter More Than Ever

Water control systems are essential technologies that monitor, measure, and manage the flow and quality of water in residential, commercial, industrial, and municipal applications. Whether you’re looking to optimize irrigation, protect equipment, or ensure water quality, modern systems offer proven solutions backed by advanced sensors, automated controls, and real-time monitoring.

Quick Buyer’s Guide – Water Control Systems by Application:

| Application | Key System Type | Primary Benefit | Typical Water Savings |

|---|---|---|---|

| Residential Irrigation | Weather-based or soil moisture controllers | Prevents overwatering | 15,000 gallons/year per home |

| Commercial Buildings | Integrated flow control with sensors | Prevents stagnation, protects equipment | 15-40% reduction |

| Industrial Processes | Automated monitoring with remote access | Leak detection, process optimization | 15-40% reduction |

| Municipal Water Supply | Battery-powered remote monitoring | Detects water loss, manages distribution | Varies by network size |

Water scarcity is a growing concern. In the United States alone, nearly 8 billion gallons of water are used daily for outdoor irrigation, and experts estimate that up to 50 percent of this is wasted due to inefficient systems. Climate change and drought accelerate these challenges, making efficient water management critical for everyone.

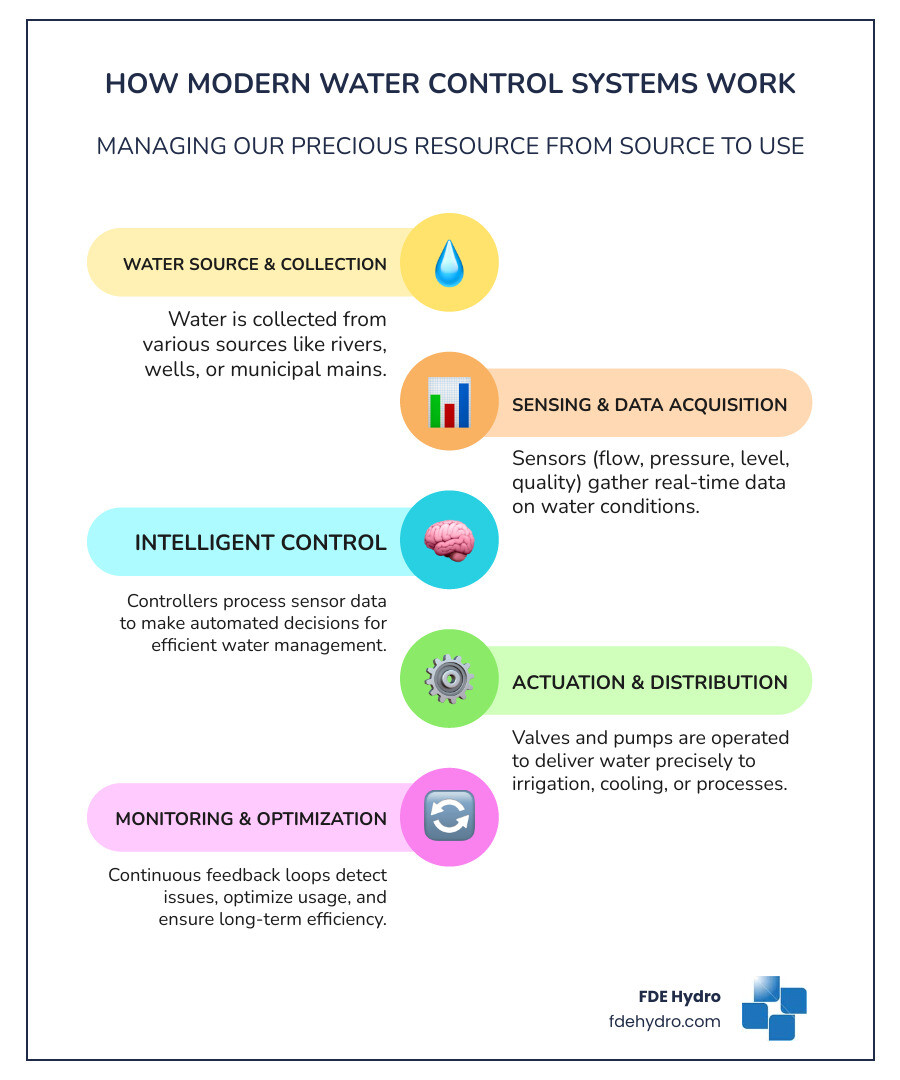

Modern water control systems address these issues through intelligent automation. Instead of relying on fixed timers, today’s systems use sensors to track weather, soil moisture, pressure, and flow rates in real time. Controllers process this data to automatically adjust valves and pumps, delivering exactly what’s needed—no more, no less.

Beyond conservation, these systems protect equipment like pumps from damage, detect leaks before they become disasters, and integrate with Building Management Systems (BMS) for centralized control. The returns are measurable: replacing a basic timer with a smart irrigation controller can save 15,000 gallons per household annually, while commercial and industrial installations routinely achieve 15-40% water use reductions.

From residential landscapes to hydropower facilities, water control systems are critical for managing one of our most precious resources. They combine sensors (flow meters, pressure transducers), actuators (valves, pumps), and intelligent controllers into integrated systems that operate autonomously, alert users to problems, and provide data for continuous improvement.

As Bill French Sr., Founder & CEO of FDE Hydro™, I’ve spent decades on large-scale civil construction and hydropower projects where effective water control systems are fundamental to success and safety. My work has reinforced that whether you’re managing a small well or a major treatment facility, the principles of smart, reliable water control remain the same.

Key Applications Across Sectors

Water control systems touch nearly every part of our lives, adapting to meet the unique demands of each sector—whether that’s keeping a lawn green without waste, maintaining water quality in a hospital, or managing millions of gallons in an industrial facility.

Let’s look at where these systems make the biggest difference.

Residential & Landscape Applications

If you’ve ever seen sprinklers watering the sidewalk during a rainstorm, you’ve witnessed the problem of inefficient irrigation firsthand. Up to 50 percent of outdoor water use is wasted through overwatering and poorly timed systems.

Advanced irrigation controllers have changed this completely. Instead of running on a fixed schedule, these smart systems think about what your landscape needs. Weather-based controllers adjust watering based on local conditions like temperature and rainfall. Soil moisture-based controllers go further, using in-ground sensors to stop irrigation the moment your soil has enough water.

The EPA’s WaterSense program certifies controllers that meet strict efficiency standards. Swapping an old timer for a WaterSense model can save the average home 15,000 gallons per year. If every U.S. home with automatic sprinklers made this switch, we’d save 390 billion gallons of water and $4.5 billion annually.

Beyond irrigation, water control systems manage other critical home needs. They provide reliable automation for sump pumps to prevent flooding and monitor well water systems to keep pumps from running dry and burning out. Modern systems use durable stainless steel sensors with no moving parts, delivering 99% uptime over a 15-year lifecycle.

Commercial & Building Systems

Commercial buildings face complex water management challenges, balancing efficiency with health and safety codes.

In plumbing system design, specialty valves are crucial for preventing water stagnation, which can lead to the growth of bacteria like Legionella. These systems ensure water keeps moving and maintains safe temperatures.

For cooling towers, old mechanical float switches are unreliable. Electronic sensors solve this by integrating seamlessly with Building Management Systems (BMS), providing real-time level monitoring to prevent costly overflows or downtime.

For fire protection systems, reliability is non-negotiable. Modern water control systems designed for fire protection tanks maintain less than 1% failure rates over 15 years, ensuring water is always available in an emergency.

HVAC systems and high-purity water applications in labs require equally precise control for heating and cooling loops or maintaining purity standards for research. We understand how these systems integrate into large-scale projects, which is why we approach every installation with careful planning. You can learn more about our process on our Means and Methods page.

Industrial & Municipal Water Control Systems

The stakes get even higher at industrial and municipal scales, where water control systems impact public health, environmental compliance, and economic productivity.

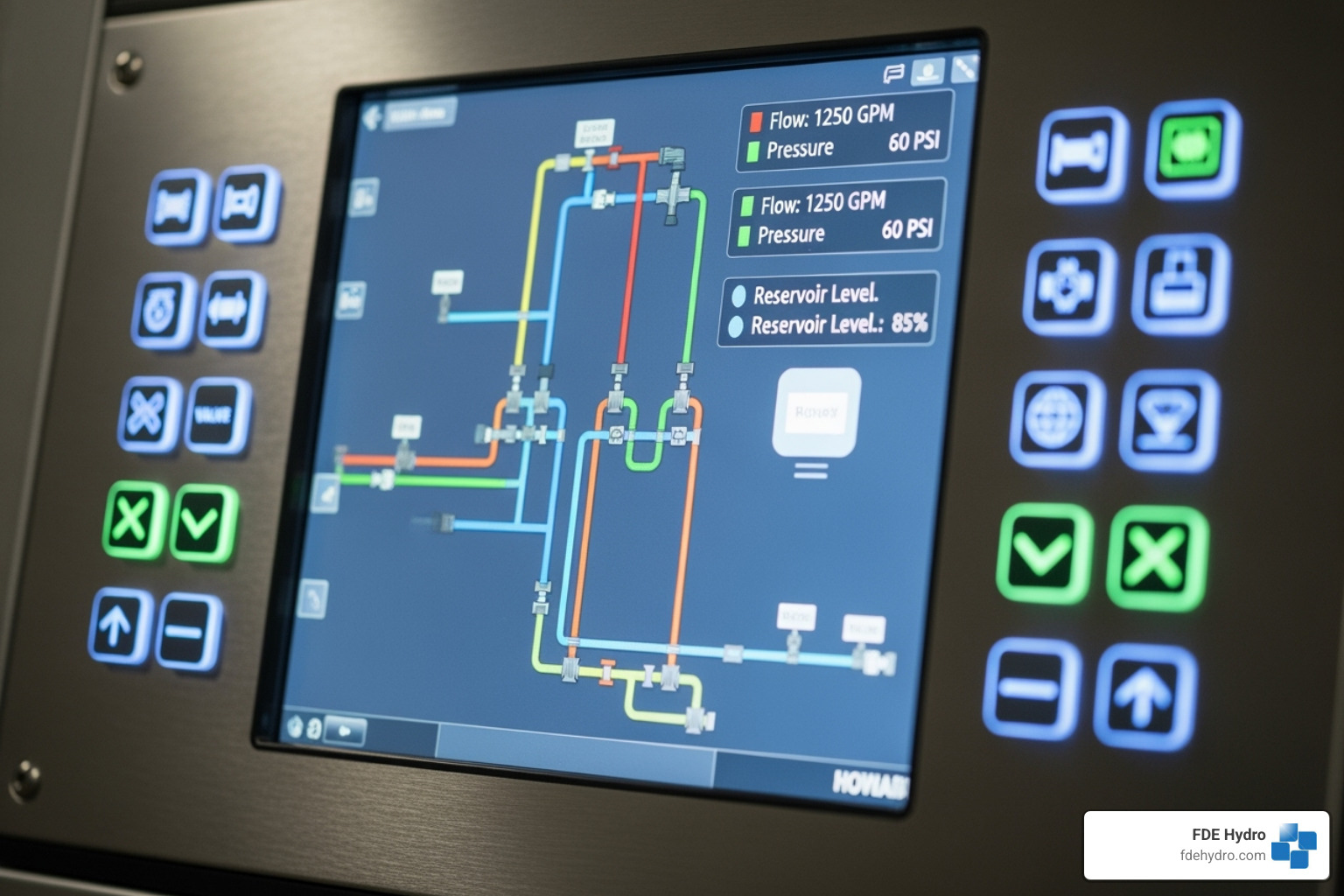

Wastewater treatment plants and process water systems rely on sophisticated controls to manage everything from intake to discharge, ensuring regulatory compliance while optimizing efficiency. These systems track flow rates, pressure, and chemical levels, making real-time adjustments.

Many industries use build-own-operate models for their water systems, letting specialists handle reverse osmosis, water softening, and ultrapure water production. Preventative maintenance programs are key to avoiding catastrophic failures.

Municipal water networks benefit enormously from remote monitoring. Battery-powered systems can operate for up to five years, transmitting data via cellular networks. Operators can track consumption in real time, spotting leaks between valves before they waste thousands of gallons and ensuring water levels in tanks and sewers stay within optimal ranges.

Water reclamation, seawater desalination, and condensate polishing all depend on precise flow control managed by regulators, restrictors, and sensors across diverse applications.

At FDE Hydro, our work extends to the largest scale of water management. We design and build Water Control Structures and Spillways that manage massive water volumes for flood control and hydropower, representing water control systems at their most critical.

Core Components of Modern Water Control Systems

Every effective water control system relies on three elements working together: sensors that gather information, actuators (like valves and pumps) that take action, and controllers that make intelligent decisions. This integration enables the automation, real-time monitoring, and equipment protection that keeps systems running smoothly.

Think of it as a coordinated team: sensors watch and measure, controllers process information and decide, and valves and pumps do the work. When all three work in harmony, the system responds instantly to changing conditions and uses only the water truly needed.

Sensors and Monitors

Sensors are the eyes and ears of a water control system, gathering data on water flow, pressure, level, and quality.

Flow meters and turbines, like those from Signet or Autotrol, measure water volume and velocity, which is essential for detecting leaks and optimizing irrigation. Level sensors, such as the robust stainless steel models from Waterline Controls, monitor tanks and wells to prevent overflows or dry-running pumps. Pressure transducers identify blockages and protect equipment like hydrophores from damaging pressure fluctuations. Water quality monitors, including Hach hardness monitors, assess parameters like pH or conductivity to ensure regulatory compliance and prevent equipment damage. Finally, temperature sensors are key for managing health risks like Legionella in building systems.

Valves, Pumps, and Regulators

If sensors are the eyes and ears, then valves, pumps, and regulators are the muscles. They take action based on commands from the controller.

Control valves and automatic valves, such as reliable Fleck/Pentair models, regulate water flow in response to controller signals, especially in water treatment processes.

Backflow preventers are a critical safety feature, protecting potable water supplies by preventing contaminated water from flowing backward into the clean system.

Flow restrictors and regulators from companies like Cannon Water Technology manage fluid dynamics in industrial applications, ensuring consistent flow rates regardless of pressure changes.

Hydrophore pumps are often used with storage tanks or alternative water sources. Intelligent water control systems protect these pumps by ensuring they never run dry.

Solenoid valves are electrically operated components that quickly open or close to control water flow, making them a go-to choice for automated systems.

Controllers and Software

The controller is the brain of the operation. It interprets sensor data, makes decisions, and sends commands to the valves and pumps.

Electronic controls and microcontrollers are the core processing units. The ESP32 microcontroller is a versatile choice for custom systems due to its built-in Wi-Fi and Bluetooth capabilities.

Programmable Logic Controllers (PLCs) are industrial-grade computers that automate complex processes in municipal and industrial settings, built for 24/7 reliability.

Remote monitoring and IoT integration have transformed water management. Systems like MTA Messtechnik’s WCS use battery-powered units and mobile networks to allow remote access from any web browser. Data logging tools, such as Cannon Water Technology’s Carlon Car-Logger, enable historical analysis for continuous optimization.

Battery-powered systems solve a critical challenge for remote locations without reliable power, with some units operating for up to five years on a single charge.

User interfaces, whether a local display or a web portal, make this technology accessible, allowing you to configure and manage your water control system without needing an engineering degree. A study on modern system design explores how these components integrate to create robust, user-friendly solutions.

Designing for Efficiency and Conservation

The real magic of water control systems isn’t in any single component—it’s in how they come together. A thoughtfully designed system is a powerful tool for conservation, delivering measurable water and cost savings.

The System Design & Implementation Process

Creating an effective water control system requires careful planning, as each application has unique needs demanding a custom approach.

An effective system follows a clear process: an initial design phase to define requirements, documentation and submittals for clarity, system fabrication of custom-built components, and finally, on-site commissioning and startup to test and fine-tune the system. Clear documentation and proper commissioning are crucial for preventing costly mistakes and ensuring long-term performance.

Sizing calculators are invaluable tools during the design phase, helping engineers select the right equipment capacity for applications like industrial reverse osmosis or water softeners. Correct sizing prevents wasting money on oversized equipment or suffering from inadequate performance with undersized systems.

At FDE Hydro, we’ve seen how construction efficiency impacts the success of water infrastructure. Our modular precast concrete technology—”French Dam” technology—dramatically reduces construction time and costs for large-scale water control structures. This efficiency extends to the water control systems themselves, making the entire project more cost-effective. It’s one of the key reasons Why Precast Cost Less.

Maximizing Water Savings with Advanced Technology

The numbers tell a compelling story about what modern water control systems can achieve.

A home that switches to a WaterSense labeled irrigation controller saves 15,000 gallons of water annually. For commercial properties, the savings scale dramatically. For example, a Dallas office complex cut water use by 40%, saving 12.5 million gallons and achieving a 1.5-year payback on its smart irrigation system. Another installation achieved a 66% water savings by connecting smart controls to the building’s automation system. These are sound financial investments with rapid returns.

Leak detection is the unsung hero of water conservation. Systems with flow and pressure sensors can spot hidden leaks almost immediately by detecting abnormal flow patterns or pressure drops, alerting you before they become expensive disasters.

Pressure management also plays a key role. High water pressure stresses plumbing and increases consumption. Pressure reducing valves lower inlet pressure to optimal levels, protecting the system and reducing waste.

For irrigation, automated scheduling has revolutionized water use. Smart controllers adjust based on real-time weather data or soil moisture readings, eliminating the wasteful overwatering common with fixed timers.

In industrial settings, precise flow control enables more efficient chemical dosing. By knowing the exact volume of water being treated, you can add the precise amount of chemicals needed, reducing costs and improving effectiveness.

The broader impact of these technologies is profound. As we face increasing climate challenges, water management becomes critical infrastructure. At FDE Hydro, we believe that The Biggest Untapped Solution to Climate Change is in the Water. Smart water control systems are about building a sustainable future where every drop counts.

Frequently Asked Questions about Water Control Systems

You’ve learned a lot about water control systems, but you might still have some practical questions. Let’s tackle the most common ones.

How do smart water control systems conserve water?

Smart systems use real-time data to make intelligent decisions. Instead of fixed timers, weather-based controllers check for rain and humidity, while soil moisture sensors measure water levels directly at the plant roots. This precision eliminates overwatering. In larger facilities, they also provide immediate leak detection and pressure optimization, preventing waste and saving money. A typical home can save 15,000 gallons annually, with commercial sites often seeing 40-70% reductions in water use.

What are the main components I need for a basic water control setup?

Every water control system follows a basic sense, think, act logic.

- Sensors to measure what’s happening (e.g., a water level sensor in a tank or a flow meter in a pipe).

- A controller (the brain) to process that information and decide what to do.

- Actuators (e.g., a valve or pump) to carry out the controller’s decision.

For example, a level sensor in a tank tells a controller when the water is low. The controller then activates a valve to refill the tank and tells it to close when the sensor signals the tank is full. It’s a simple, reliable, and automatic process. More complex systems add more specialized sensors for pressure or water quality, but the basic framework remains the same.

Can these systems be integrated into an existing building or facility?

Absolutely. Modern water control systems are designed with retrofitting in mind. You don’t need to start from scratch.

Wireless sensors eliminate the need to run new wiring, and modular controllers can be added to existing setups. Most importantly, standard communication protocols allow new components to talk to your existing Building Management Systems (BMS) or industrial control networks. For example, electronic sensors can use dry contacts to integrate seamlessly with a BMS for centralized monitoring.

Remote monitoring systems that connect via mobile networks are another easy integration, sending data to a web server you can access from anywhere. The key is working with experienced professionals who can ensure the new water control systems work harmoniously with what you already have, resulting in a more efficient system that delivers measurable savings.

Conclusion

From smart irrigation in a backyard to sophisticated systems managing municipal water networks, the message is clear: water control systems are essential infrastructure. They are no longer a ‘nice-to-have’ but a necessity for a sustainable future.

The numbers represent real conservation and cost savings. A single household can save 15,000 gallons annually, while commercial facilities often reduce water use by 15-40% or more. When multiplied across thousands of sites, the impact is profound.

Reliability is just as important as savings. Modern water control systems protect expensive equipment, detect leaks before they become disasters, and ensure water quality through continuous monitoring. They work around the clock, making small adjustments that lead to major improvements in efficiency.

The future of water management is smart and connected. Battery-powered sensors, remote monitoring, and IoT integration are changing how we interact with water infrastructure, moving us from reactive management to proactive stewardship.

At FDE Hydro, we see this change daily. Our innovative modular precast concrete technology—”French Dam” technology—creates the physical structures that support these sophisticated water control systems. Whether it’s a new hydropower facility or a retrofitted dam, the principles are the same: efficiency, reliability, and sustainability built from the foundation up.

Water is our most precious resource, and managing it wisely is not optional. We have the technology and knowledge to do it right. From residential landscapes to renewable energy projects, water control systems prove that conservation and performance go hand in hand.

If you’re interested in learning how we’re applying these principles to renewable energy and large-scale water management, I invite you to explore our innovative solutions for Hydropower. Together, we can build a future where every drop counts.