Why Water Control Systems Matter More Than Ever

A water control system is infrastructure designed to regulate, monitor, and manage the flow, distribution, and quality of water. Combining hardware (sensors, valves, pumps) with software (SCADA platforms, IoT dashboards), these systems ensure efficient water use, prevent damage, and support sustainability goals.

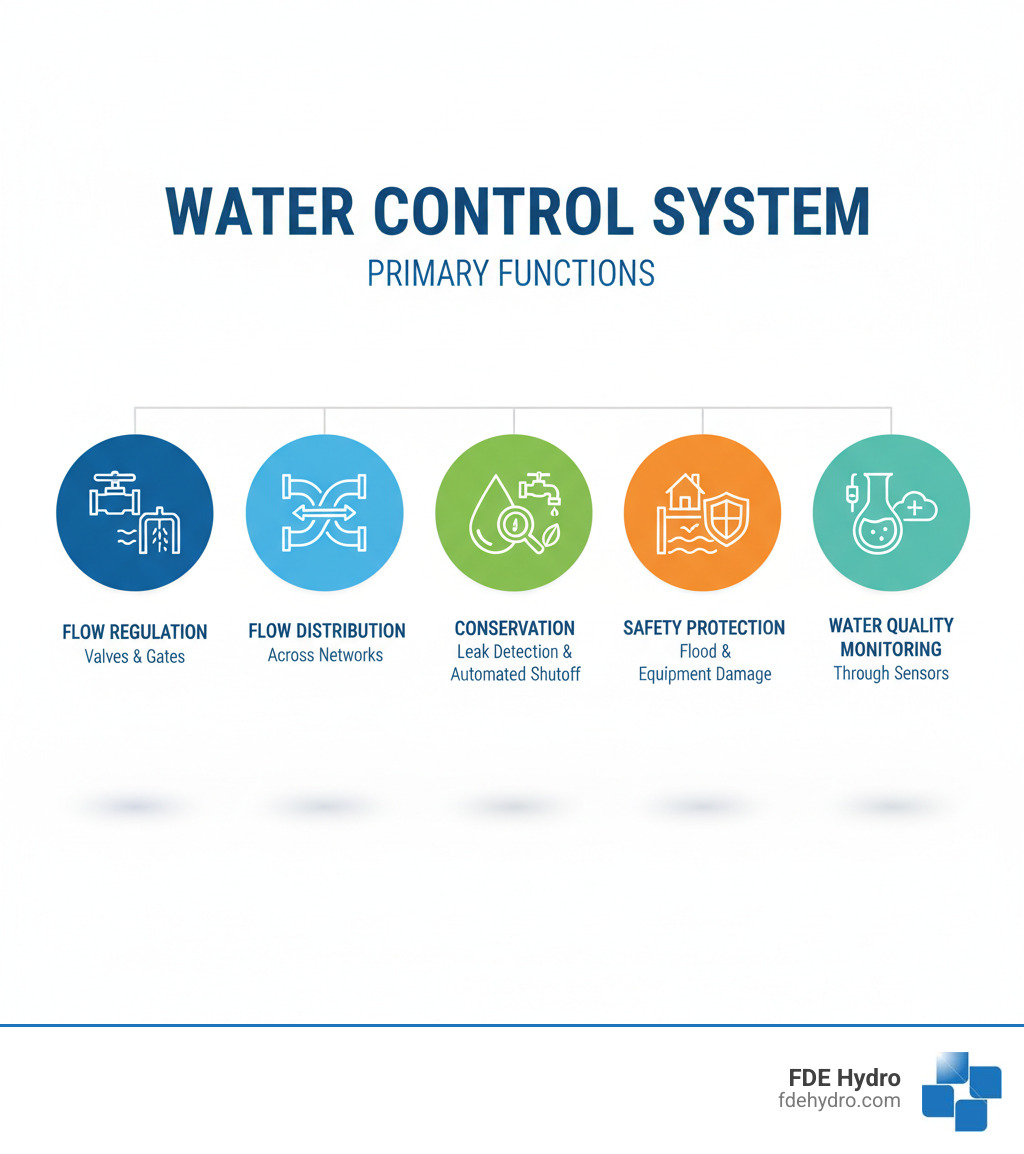

Key functions of water control systems include:

- Flow Regulation – Controlling water volume and pressure through pipes, canals, or reservoirs

- Distribution Management – Ensuring water reaches intended destinations efficiently

- Conservation – Reducing waste through leak detection, automated shutoff, and optimized usage

- Safety Protection – Preventing floods, equipment damage, and infrastructure failures

- Quality Monitoring – Tracking contamination, sediment, and chemical levels

The need for better water control is urgent. Water scarcity affects more than 40% of the world’s population—a figure expected to rise with climate change. Reflecting this, the global smart water management market is projected to reach $27.8 billion by 2030 as industries and municipalities invest in smarter systems.

These systems deliver significant savings: municipal water loss can be cut by up to 20%, agricultural water use by 15-30%, and industrial energy costs by 10-25%. For homeowners, automated shutoff systems can prevent an average of $10,000-$15,000 in leak-related damages.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, where we develop modular civil construction solutions for the hydropower industry. With over five decades in heavy civil construction, I’ve learned that efficient water management is the backbone of resilient infrastructure. At FDE Hydro, we focus on innovative water control systems that benefit both present and future environments.

What Are the Core Functions of a Water Control System?

A water control system’s core mission is to ensure water goes where it needs to, when it needs to, and in the right amount. Its primary functions work in harmony to achieve this.

Water regulation and distribution are the most fundamental jobs. This means controlling the volume and pressure of water flowing through pipes, canals, or reservoirs to meet demand precisely. Whether keeping pressure steady in a home or managing levels at Dams for hydropower, this control is essential for efficiency and reliability.

Conservation has become critical as water scarcity and climate change intensify. Modern water control systems tackle this through smart leak detection, automated shutoffs, and optimized scheduling. These technologies are vital for creating Sustainable Water Infrastructure and have a massive impact in agriculture, which accounts for 70% of global freshwater use.

Safety and protection are equally important. By monitoring water levels and controlling releases through gates and Spillways, these systems protect communities from floods. They also perform water quality management by using sensors to track contaminants and sediment. At the same time, they provide equipment protection by preventing pumps from running dry or safeguarding turbines from debris, extending the life of infrastructure investments. As scientific research on water resources and climate change highlights, such integrated management is essential for climate adaptation.

Anatomy of a Modern Water Control System

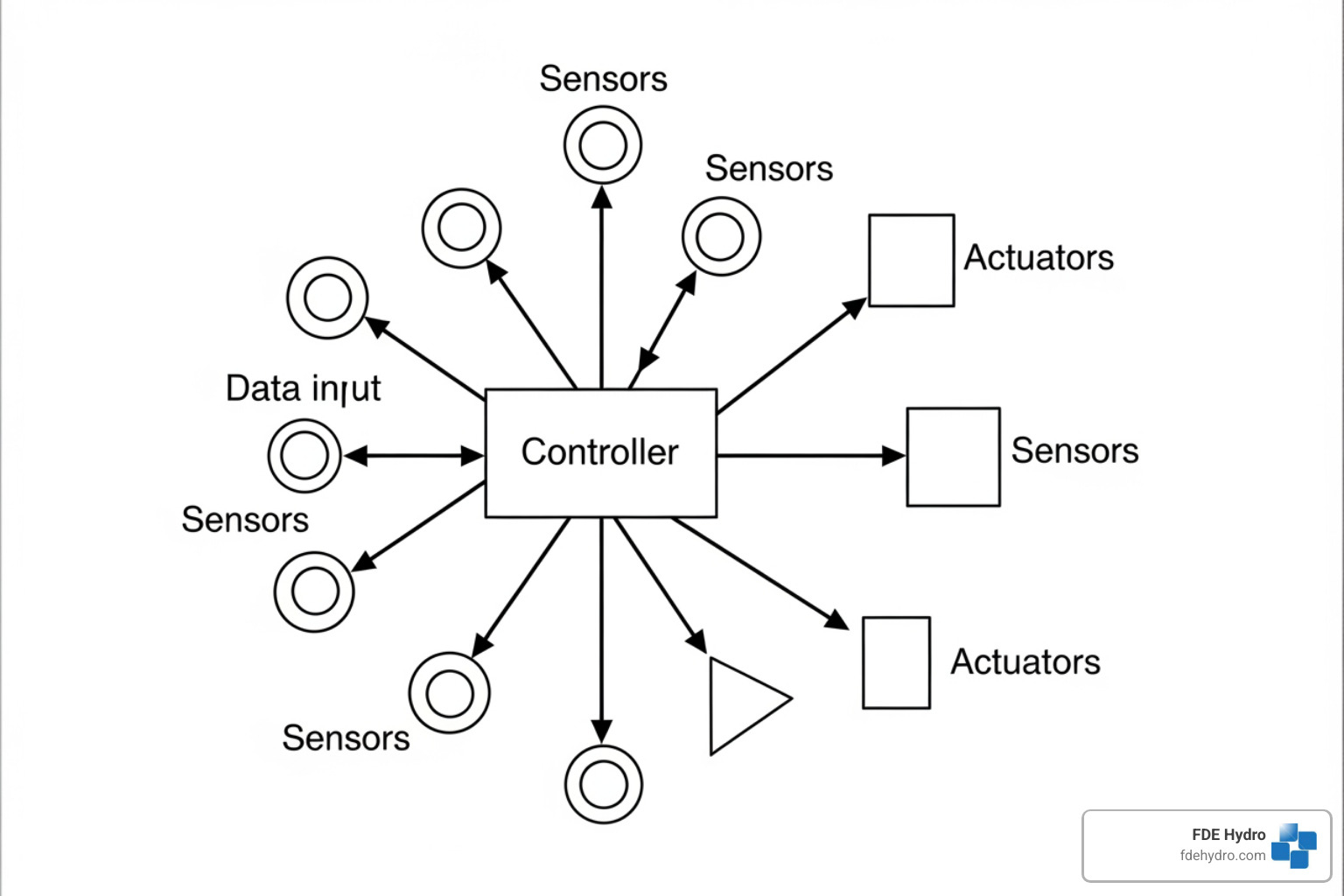

A modern water control system integrates hardware and software to manage water with precision.

This section explains the key components of a modern water control system, showing how they work together to achieve optimal water management.

Key Hardware Components

Hardware components are the physical parts of the system that perform sensing and control actions.

- Sensors gather critical data. Flow sensors measure water speed, while pressure sensors monitor pressure and can even detect minute leaks. Level sensors, such as reliable pressure transducers or simpler float switches, track water levels in tanks and reservoirs. Quality sensors monitor pH, turbidity, and chemical composition.

- Actuators perform the physical work. Valves control flow and pressure, ranging from manual to sophisticated automatic control valves. Pumps move water where it needs to go. Control gates are massive structures that manage large water flows at Water Control Structures and hydroelectric facilities.

- Controllers are the system’s brain. Programmable Logic Controllers (PLCs) handle complex industrial automation, while smaller Microcontrollers (like the ESP32) are ideal for IoT applications. Remote Terminal Units (RTUs) enable remote monitoring and control.

- Communication Networks like radio, cellular, or wired connections link these components, enabling real-time management.

Software and Intelligent Control

Software transforms the hardware into a truly smart water control system.

Centralized control platforms (often SCADA systems) provide a complete, real-time overview of the entire water network. IoT dashboards make this data accessible from anywhere, allowing an operator to check a well’s water level or monitor industrial usage from a phone.

Data analytics and predictive modeling analyze historical data to spot trends, predict equipment failures, and optimize operations. For example, comparing rainfall data with well recovery rates provides powerful information for planning.

This intelligence is improved by integration with industrial automation, creating an interconnected framework that improves overall efficiency. At FDE Hydro, we advance these capabilities through AI-Driven Development, using artificial intelligence to make systems smarter. The Design and Implementation of an Automated Water Monitoring and Control System shows how microcontrollers can create autonomous systems that ensure reliable supply without constant human intervention.

Applications Across Sectors: From Homes to Hydropower

The versatility of a water control system allows it to be adapted for vastly different applications, from a single home to a massive hydroelectric facility. While the principles of monitoring and managing water remain the same, the scale and goals vary by sector.

| Sector | Primary Goals | Common Technologies | Scale |

|---|---|---|---|

| Residential | Leak prevention, water conservation, comfort | Smart shut-off valves, leak detectors, smart irrigation, water softeners | Single home to apartment complex |

| Agricultural | Efficient irrigation, crop yield optimization | Smart irrigation controllers, soil moisture sensors, automated canal gates, flow meters | Small farm to large-scale irrigation district |

| Industrial | Process efficiency, equipment protection, compliance | Water level controls (cooling towers), flow control systems, wastewater treatment controls | Single plant to multi-site operations |

| Municipal | Distribution, quality, flood control, resource management | SCADA systems, smart meters, pressure regulation, dam controls, flood sensors | City-wide to regional water authority |

Residential and Commercial Systems

In homes and commercial buildings, water control systems work quietly to protect property and conserve resources. Leak detection with automated shutoff valves is a key feature, immediately closing the main water supply when a burst pipe is detected to prevent catastrophic water damage. In colder climates like Canada and the northern U.S., some systems also monitor temperature to prevent pipes from freezing and bursting.

Smart irrigation timers adjust watering schedules based on local weather data, conserving water while keeping landscapes healthy. In commercial buildings, sub-metering tracks usage by tenant to promote accountability, while water softeners and filtration systems improve water quality.

Agricultural Water Control

With agriculture being the largest consumer of freshwater, efficient water control systems are essential for global food security. Precision irrigation uses data from soil moisture sensors to deliver water directly to crop root zones, minimizing waste and maximizing yields. This technology is a genuine win-win for farmers and the environment.

Canal automation scales up this efficiency. Instead of manual gate adjustments, automated systems coordinate gates along entire canal networks to ensure consistent flow and eliminate spillage, making open canals nearly as precise as pressurized pipes at a fraction of the cost. For more insights, explore our page on irrigation control systems.

Industrial and Municipal Infrastructure

At the industrial and municipal scale, water control systems are feats of engineering managing enormous volumes of water. In process water management, they maintain exact water levels and flow rates critical for cooling towers, refineries, and manufacturing. Optimized controls can significantly reduce energy consumption from pumping.

Wastewater treatment plants rely on these systems to regulate chemical dosing and biological processes to meet strict environmental regulations. Municipal distribution networks use advanced SCADA systems to monitor thousands of miles of pipes, manage pressure, detect leaks, and ensure reliable service to millions of customers.

Flood control infrastructure, including dams and Spillways, protects communities by managing extreme water flows. At FDE Hydro, we contribute our expertise to these critical Water Control Structures, as detailed in our Hydroelectric Dam Components Ultimate Guide.

The Advantages of Automation and Smart Technology

The shift toward automated water control systems is a practical pathway to efficiency, sustainability, and significant cost savings.

This section details the benefits of implementing an automated water control system.

Cost Savings and Efficiency

The financial case for automated water control systems is compelling. They lead to significant cost savings through reduced water loss, as every gallon saved is money that doesn’t need to be spent on sourcing, treating, and pumping. This leads directly to lower energy consumption, as pumps run only when needed and at optimal speeds.

Automation also minimizes labor costs by freeing personnel from manual monitoring and adjustments to focus on more complex tasks. Perhaps most importantly, these systems help prevent costly equipment failures. By continuously monitoring equipment health and detecting anomalies early, they can shut down machinery before catastrophic damage occurs, saving far more than the initial investment. Our work at FDE Hydro demonstrates this principle, using efficient methods like those in Why Precast Cost Less to build more resilient and cost-effective infrastructure.

Improved Conservation and Compliance

Beyond financial gains, automated systems are powerful tools for environmental stewardship. They make meeting regulatory standards in regions like the United States and Europe almost effortless by providing precise, consistent control and detailed records for reporting.

By reducing water waste and energy use, these systems directly contribute to achieving sustainability goals. This aligns with our mission at FDE Hydro to develop sustainable solutions like hydropower, which offers many environmental advantages as detailed in the Benefits of Hydropower Plant. The accurate usage data they provide transforms water management from guesswork into a science, enabling informed planning and demonstrating a commitment to reducing environmental impact.

Challenges, Maintenance, and Future Innovations

While modern water control systems offer incredible benefits, they require thoughtful planning, ongoing maintenance, and adaptation to new challenges.

The initial investment costs can be substantial, particularly for large-scale projects. However, the long-term savings from reduced water loss, lower energy bills, and prevented failures often provide a clear return on investment. Another growing concern is cybersecurity vulnerabilities. As critical infrastructure becomes connected, robust security protocols are essential to protect communities from service disruptions or safety hazards. Finally, system integration complexity requires expert implementation, especially when upgrading Aging Infrastructure Being Replaced with Next Generation Civil Solutions with a mix of old and new components.

Installation and Maintenance Considerations

Proper installation and maintenance are key to a system’s longevity and performance. This begins with a thorough site assessment to understand existing infrastructure and environmental challenges. Component selection is also critical; sensors and actuators must be rated for the specific operating environment to ensure reliability.

Ongoing tasks include periodic sensor calibration to maintain accuracy and managed software updates to patch vulnerabilities and add features. Despite automation, regular physical inspections by trained personnel remain irreplaceable for spotting leaks, corrosion, or physical damage. For major infrastructure, specialized approaches like Dam Rehabilitation Encapsulation offer innovative solutions for extending service life.

The Future of Water Control Technology

The future of water control system technology is being shaped by powerful innovations.

Digital twins, virtual replicas of physical water systems, allow engineers to simulate scenarios and optimize strategies without real-world risk. AI for predictive maintenance is evolving to analyze complex data patterns and anticipate equipment failures weeks in advance, minimizing downtime. At FDE Hydro, our work with AI-Driven Development explores how these technologies can optimize both construction and operations.

Advanced non-invasive sensors promise easier and more reliable monitoring without direct water contact, reducing installation costs. Decentralized control systems are also emerging, creating more resilient networks where segments can operate autonomously. At FDE Hydro, we focus on Using Technology to Minimize the Duration of Impacts to build smarter systems faster, more affordably, and with less environmental impact.

Conclusion

We’ve seen how water control systems are essential for regulating flow, distributing water, conserving resources, and ensuring safety. From the hardware of sensors and actuators to the intelligence of modern software, these systems are versatile tools with applications in our homes, on our farms, and across our cities.

The benefits are compelling. Intelligent automation leads to significant savings in water and energy, reduces operational costs, and prevents costly disasters. More importantly, this technology represents a collective commitment to managing water more responsibly. With a large portion of the world’s population facing water scarcity, we cannot afford to waste this vital resource.

At FDE Hydro, this mission is personal. Our innovative, patented modular precast concrete technology—the “French Dam”—is designed to make building and retrofitting hydroelectric dams and water control infrastructure faster, more cost-effective, and more sustainable across North America, Brazil, and Europe.

The future is bright, with innovations like digital twins, AI-driven predictive maintenance, and advanced sensors set to make our water systems even smarter and more resilient. We are embracing these technologies to deliver reliable, efficient, and sustainable water management.

Whether you’re managing a farm, an industrial facility, or municipal infrastructure, understanding water control systems is crucial. To learn more about how advanced water control contributes to renewable energy and sustainable infrastructure, explore our resources on Hydropower and our comprehensive guide to Water Control Systems.