Why Water Control Structures Matter for Modern Infrastructure

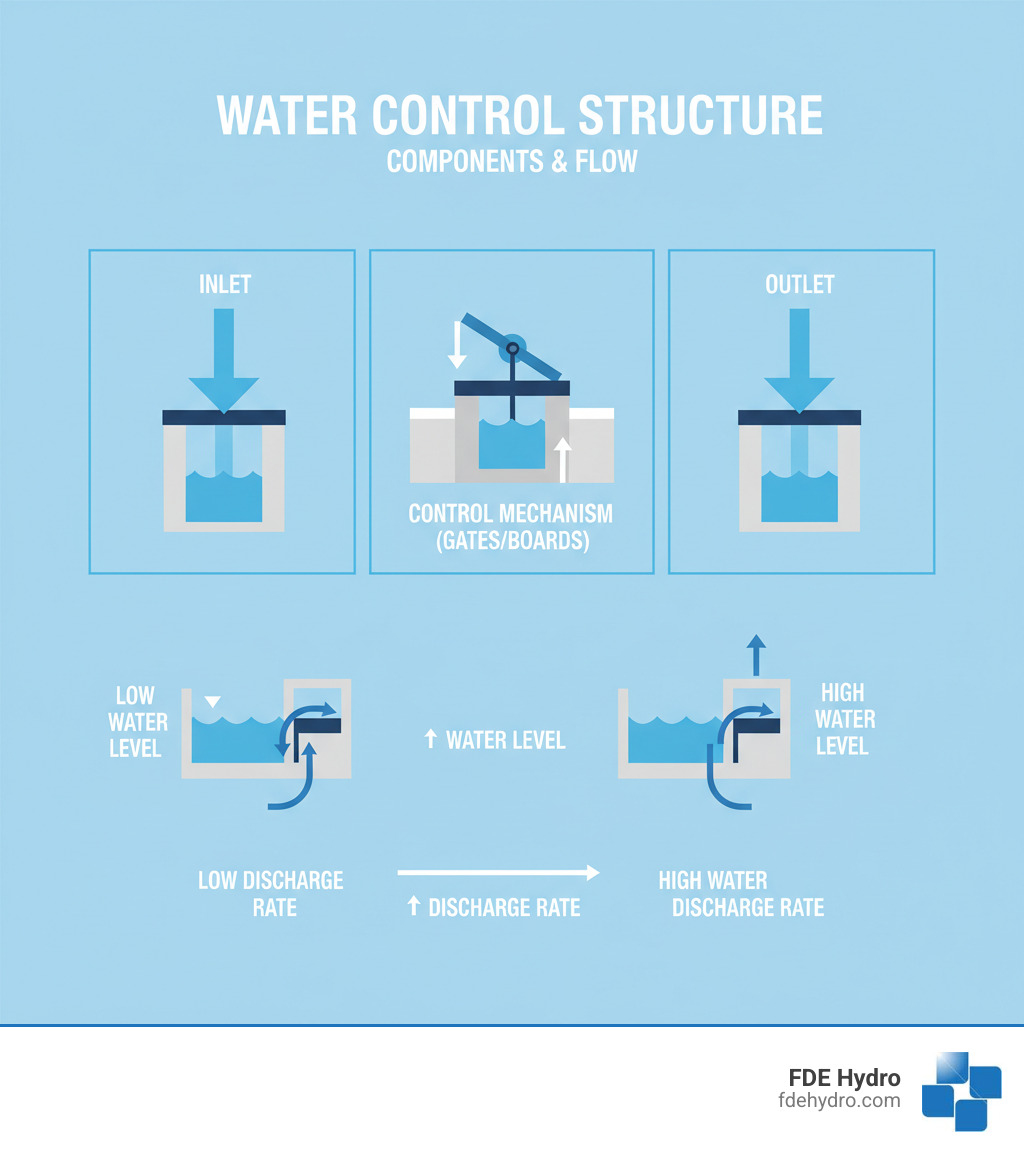

Water control structures are permanent installations that control the stage, discharge, and direction of water flow in channels, pipes, and waterways. These hydraulic devices serve critical functions, including:

- Flow Management – Controlling the rate and direction of water movement.

- Water Level Control – Maintaining desired water levels in reservoirs and drainage systems.

- Quality Improvement – Reducing sediment and nutrient discharge.

- Habitat Creation – Supporting fish and wildlife through managed water conditions.

- Flood Risk Reduction – Impounding and releasing water to protect downstream areas.

- Agricultural Support – Managing drainage and irrigation for crop production.

These structures range from simple flashboard risers to complex automated gates, with costs varying from hundreds to many thousands of dollars for engineered systems.

The terminology has evolved from “flood control” to “flood risk management,” reflecting that structures reduce, not eliminate, water-related risks. This shift mirrors a broader understanding of working with natural systems instead of dominating them.

Modern water infrastructure faces mounting challenges from high costs, long timelines, and climate change, which requires adaptable structures. The need for innovation has never been greater.

I’m Bill French Sr., Founder and CEO of FDE Hydro. With over five decades in heavy civil construction, I’ve focused on developing modular water control structures for the hydropower industry that reduce construction time and costs while improving environmental outcomes.

The Core Functions of Water Control Structures

Water control structures are the workhorses of modern water management, performing essential tasks that touch nearly every aspect of our lives. From our food to the health of our rivers, these structures do the heavy lifting. Let’s explore how they make a difference across three critical areas.

Managing Water for Agriculture and Conservation

When you think about farming, you might picture tractors and combines, but beneath many productive fields lies an intricate network of drainage systems—and water control structures are the valves that make them work intelligently.

These structures excel in flatter landscapes where land slopes are less than 0.5 percent. Installed in farm canals, ditches, or subsurface drain tiles, they offer a dual benefit: helping crops thrive while protecting downstream water quality.

By raising the water table in fields with subsurface drainage, these structures slow drainage outflow and create conditions for denitrification—a natural process where bacteria convert harmful nitrates into harmless nitrogen gas. The result is cleaner water flowing into streams and rivers.

The precision is remarkable. For corn, farmers might maintain water levels 12 to 18 inches below ground in spring and fall, dropping them during peak growth. When managed correctly along at least 50 percent of a ditch, keeping water within 30 inches of the surface can drastically cut nitrate losses and often leads to improved crop yields.

In conservation areas like riparian buffers, water control structures help restore natural water flow patterns. Raising the water table in these vegetated zones boosts their ability to filter pollutants. The Conservation Practice Standard Structure for Water Control (Code 587) provides detailed guidance on implementing these systems for maximum environmental benefit.

Controlling Stormwater and Preventing Floods

The shift from “flood control” to “flood risk management” reflects that we can reduce flood risks, but not eliminate them. Water control structures are central to this reduction strategy.

A reservoir behind a dam captures storm runoff, which is then released gradually via water control systems at rates the downstream channel can handle. This process smooths a dangerous flow spike into a manageable stream.

The U.S. Army Corps of Engineers manages this balance across watersheds using reservoirs, levees, and diversions. Their Management of Water Control Systems manual details how they coordinate objectives like flood reduction, water supply, and environmental protection.

A properly designed structure must discharge the design flow rate with no more than a 0.5-foot head (the water level difference across the structure). In spillways, features like concrete piers slow water to prevent erosion.

In urban areas, smaller water control structures manage runoff from pavement, reducing downstream surges and sediment loads that would otherwise harm aquatic life.

Creating and Protecting Natural Habitats

Water control structures are powerful tools for environmental restoration and habitat preservation. With thoughtful design, these structures can revive degraded ecosystems.

Wetland restoration is a perfect example. By managing water levels to create saturated conditions, we can rebuild wetlands that mimic natural patterns, creating havens for wildlife while filtering pollutants.

Water temperature regulation through cold water release structures is vital for downstream fisheries. By drawing water from various reservoir depths, we can influence release temperatures to support species like trout and salmon.

Timing also matters. Managing water levels for spawning might mean maintaining stable reservoir levels during critical breeding periods or using timed drawdowns to improve feeding opportunities for juvenile fish.

We ensure aquatic animal and recreational passage around our structures with fish ladders and other facilities. These allow migrating species to move freely, changing potential barriers into supportive structures.

The goal is always balance—meeting human needs while protecting the natural systems that sustain us.

An In-Depth Look at Common Types of Water Control Structures

Water control structures come in many shapes and sizes, each designed for specific functions and environments. Think of them as tools in a toolbox—you wouldn’t use a hammer to turn a screw, and you wouldn’t use a gate where a simple weir would do the job better.

The key distinction is between passive structures, which work without any intervention once installed, and active structures, which require manual or automated adjustments to function properly. Understanding these differences helps you choose the right solution for your specific water management challenge.

Here’s a comparison of some common types:

| Feature | Flashboard Risers | Gates & Valves | Weirs |

|---|---|---|---|

| Control Type | Manual, passive | Active, manual/automated | Passive, fixed |

| Adjustability | Step-wise (board removal) | Continuous | Limited (fixed crest) |

| Primary Use | Water level management, drainage | Flow regulation, shut-off | Flow measurement, level control |

| Flow Impact | Gravity flow, adjustable | Regulated flow, on/off | Fixed overflow, flow measurement |

| Complexity | Low-moderate | Moderate-high | Low-moderate |

Flashboard Risers and Inline Structures

Flashboard risers are workhorses in agricultural settings and pond management. The design is neatly simple: a vertical structure with grooves that hold removable boards called stoplogs. Need to drain a pond for maintenance? Remove some boards. Want to raise the water level for irrigation? Add them back. It’s like adjusting the height of a dam one board at a time.

Pond risers provide the vertical conduit through which water flows, and they’re typically designed for gravity flow systems—meaning water moves naturally downhill without pumps. This simplicity is both a strength and a limitation. While these systems are reliable and require no power, they’re not pressure-rated, and you should expect some seepage. That’s just physics at work.

Inline structures take this concept underground. These are installed directly within subsurface drainage conduits like drain tiles or tubes, managing water levels beneath your fields. Installation requires replacing at least 20 feet of perforated drain pipe with non-perforated pipe connected to the structure. For single drain lines, you’ll want the drain pipe upslope of the structure to exceed 500 feet for maximum effectiveness.

A smart cost-saving approach is installing water control structures on submains where multiple drain lines discharge. This reduces the number of structures needed while maintaining control over a larger area—assuming your topography cooperates. Our Water Control Infrastructure Guide 2025 dives deeper into these design strategies and helps you make the right choices for your specific site.

Gates, Valves, and Weirs

When you need more dynamic control over water flow, gates and valves step up to the plate. Sluice gates are commonly used for managing silt in ditches and canals—slide them open or closed to control flow. Screw gates offer even finer control, allowing you to dial in precise flow rates by turning a threaded mechanism. It’s the difference between a light switch and a dimmer.

Flap gates and tide gates serve specialized roles. Flap gates act as one-way valves, letting water flow out but preventing backflow. Tide gates are particularly valuable in coastal areas, where they prevent tidal surges or high water from pushing back into freshwater channels. Nobody wants saltwater contaminating their irrigation system.

Weirs represent the passive end of the spectrum. These structures force water to flow over a crest or through a notch, and they excel at flow measurement and maintaining specific upstream water levels. V-notch weirs are perfect for measuring low flows with precision, while outlet weirs and broader designs handle larger volumes. Concrete hump weirs create a smooth, predictable overflow pattern that’s ideal for certain applications.

The beauty of weirs is their simplicity—no moving parts, no maintenance headaches. Water hits the crest and flows over in a predictable pattern that engineers can measure and calculate with remarkable accuracy. These components often integrate into larger systems, including those covered in our Hydroelectric Dam Components Ultimate Guide.

Ancillary Components and Their Roles

The stars of water control might be gates, weirs, and risers, but the supporting cast deserves recognition too. These ancillary components keep everything running smoothly and extend the life of your infrastructure.

Trash racks and debris screens are your first line of defense against clogging. They catch leaves, branches, weed seeds, and other debris before it enters pipelines or jams control mechanisms. Think of them as the bouncer at the door—keeping the troublemakers out so the party inside can continue uninterrupted.

Bar guards take this protection a step further, blocking large debris from inlets while also deterring rodents from entering pipes. A beaver or muskrat can cause surprising damage to a water control system, and prevention is far cheaper than repair.

Speaking of beavers, beaver guards are specialized structures designed to prevent these industrious animals from building dams around or within your water control structures. Beavers are remarkable engineers in their own right, but their construction projects rarely align with your water management goals.

Stilling basins appear downstream of many structures, where they serve a critical but often overlooked function. Fast-moving water carries tremendous energy, and when it exits a pipe or flows over a weir, that energy needs somewhere to go. Stilling basins dissipate this energy gradually, preventing erosion and protecting channel beds and banks from damage.

Turnouts are simple but essential for irrigation systems. These structures divert water from main channels into smaller laterals or directly into fields. They’re the traffic directors of agricultural water management.

Finally, pump boxes protect pumps and associated equipment from weather and vandalism while allowing for controlled water transfer. They might not be glamorous, but they’re practical—and in water management, practical solutions often matter most.

Design, Materials, and Installation Best Practices

Getting a water control structure right from the start makes all the difference. At FDE Hydro, we’ve learned that proper design, smart material choices, and careful installation aren’t just nice-to-have—they’re the foundation of structures that actually work for decades.

The truth is, designing these systems isn’t always straightforward. Simple prefabricated structures for subsurface drainage might not need an engineer’s stamp, but anything more complex—especially structures going into ditches or channels—absolutely requires professional engineering oversight. We’ve seen too many well-intentioned projects fail because someone skipped this step.

Here’s something critical to understand: the effectiveness of water control structures varies dramatically from site to site. What works beautifully in one location might struggle in another, even if the structures look identical on paper. That’s why we start every project with thorough engineering design, examining topography, soil conditions, and the specific hydrological outcomes you’re trying to achieve.

Before breaking ground, you’ll need permits. This isn’t red tape for its own sake—it’s about ensuring your structure meets federal, state, and local regulations that protect water quality and public safety. We always secure all required permits before construction begins. Our Hydroelectric Dam Design Complete Guide walks through many of these considerations in detail.

Common Materials and Their Impact

The materials you choose today will determine whether you’re maintaining your structure every few months or barely thinking about it for years. We’ve worked with every material imaginable, and here’s what actually performs in the field.

PVC has become our go-to for many applications, and for good reason. It resists corrosion, stays lightweight for easier installation, and holds up remarkably well in water. Our inline structures use rugged half-inch-thick PVC with anodized aluminum corner profiles and stainless steel screws. For larger structures, we increase the bottom sheet thickness to a full inch. One important note: skip plastic risers anywhere fire is a concern.

Steel brings best strength, especially for larger gates, risers, and structural supports. Corrugated steel pipes often get an asphalt coating for extra corrosion protection. We can adapt steel designs to fit directly onto various culvert pipes, which saves time and money during installation.

Concrete used to dominate the flashboard riser market, though the old designs were often expensive and labor-intensive to build. But concrete isn’t going anywhere—it remains essential for robust foundations, larger dams, and specific weir types like concrete hump weirs. The stability of a concrete control in a channel far exceeds what you’d get in sandy, flood-prone areas.

Geotextiles might not look impressive, but these specialized fabrics do heavy lifting in filtration, separation, reinforcement, and erosion control around structures. They’re often the unsung heroes that keep everything else working properly.

We design all our water control structures to last at least 20 years, balancing upfront investment with long-term performance and minimal maintenance headaches.

Key Design Considerations for Water Control Structures

Every successful water control structure starts with careful attention to several critical design elements. Miss any of these, and you’re setting yourself up for problems down the road.

Pipe sizing matters more than many people realize. We typically work with pipes from 4 inches to 12 inches in diameter, matching the required flow capacity of your drainage system. Go too small and you create bottlenecks; too large and you waste money on unnecessary capacity.

Structure height depends entirely on your water level control needs. When risers exceed six feet, we add a 3-inch by 3-inch channel for lateral support. Wider risers—from 48 inches up to 96 inches and beyond—get 3-inch wide H-beams for improved stability. These aren’t optional extras; they’re structural necessities.

Head limitations require careful calculation. The structure’s capacity must discharge the design flow rate with no more than a half-foot of head. Under cropped conditions, exceeding this 0.5-foot design head can harm your crops and reduce the structure’s effectiveness.

Anti-seep collars prevent one of the most common failure modes: pipe washout from seepage along the outside of the pipe. These rubber collars, typically 2 feet by 2 feet or 3 feet by 3 feet, work with any smooth-wall pipe or corrugated plastic tubing. Installation requires cutting a round hole about 33 percent smaller than the pipe diameter to ensure a tight seal. We always recommend using anti-seep collars with inline structures—they’re inexpensive insurance against expensive problems.

Structural reinforcement becomes critical as structures grow larger. H-beams and channels provide the lateral support and stability that keeps everything aligned and functional year after year. Cutting corners here is penny-wise and pound-foolish.

Safety measures aren’t afterthoughts—they’re designed in from the start. We incorporate features like safety railings and clear operational instructions to prevent serious injury or loss of life. Our approach aligns with proven Dam Construction Methods that prioritize both effectiveness and safety.

Installation and Maintenance Requirements

Even the best-designed water control structure will fail if installed poorly or maintained haphazardly. Here’s what actually works in the field.

Installation starts with stable base preparation. We excavate and grade the base, inlet, and outlet pipes, then create a solid, stable foundation on compacted soil or fill sand. Shortcuts here lead to settling and misalignment that only get worse over time.

Backfilling requires patience and care. We hand-tamp in 6-inch lifts around the structure, avoiding mechanical compaction or direct contact with heavy machinery that could crack or damage components. Yes, it takes longer. Yes, it’s worth it.

Pipe connections use flexible couplers secured with stainless steel clamps, creating watertight yet flexible joints that accommodate minor ground movement. The structure must be leveled vertically before backfilling—trying to adjust it afterward rarely works well.

Once installed, regular maintenance keeps everything running smoothly. Debris removal tops the list—trash, leaves, branches, and algae can dramatically alter how your control manages water. We recommend checking pipe inlets and trash racks regularly and clearing them promptly.

For structures with movable components like stoplogs, seal lubrication with a product like Lubriplate Grease ensures smooth operation and minimizes seepage. This simple step takes minutes but prevents hours of frustration later.

Vegetative protection around structures prevents erosion and stabilizes soil. Seed or sod all disturbed earth surfaces with appropriate vegetation. Where permanent vegetation struggles, mulches or gravels provide reliable protection. Don’t let bare areas persist—they’re erosion waiting to happen.

Routine inspections should happen at least twice yearly, with additional checks after major storms. Look at structures, embankments, spillways, and appurtenances for damage or blockages. Catching small problems early prevents big failures later.

Finally, create a detailed operation and maintenance plan and review it with your land manager. This plan should cover maximum, minimum, and normal water control elevations, inspection schedules, clean-out procedures, and vegetated border use. Keep operational records of structure adjustments—they’re invaluable for troubleshooting and optimization.

Neglecting maintenance doesn’t just reduce efficiency—it increases costs and risks structural failure. Our expertise in Dam Rehabilitation Encapsulation reinforces our commitment to keeping water infrastructure healthy for the long haul.

The Future of Water Management

The landscape of water management is continuously evolving, driven by the increasing demands of a growing population and the unpredictable impacts of climate change. The design and technology of water control structures are adapting to meet these challenges, moving towards more resilient, efficient, and sustainable solutions.

Looking back, the shift from labor-intensive concrete flashboard risers to prefabricated steel inlet boxes happened because we needed something more practical and affordable. Today, we’re seeing another change—one focused on adaptability and intelligent monitoring. We’re building climate change preparedness and resilience planning into everything we do, recognizing that our structures need to handle much greater variability in water levels and flow patterns.

The rise of smart water systems and remote monitoring is revolutionizing how we manage water resources. These systems use sensors and data analytics to deliver real-time information about water levels, flow rates, and quality. This means we can respond faster and optimize control like never before. The U.S. Army Corps of Engineers, for instance, uses Water Management Enterprise Systems to integrate data and improve operational decisions across their vast network. These technological advances are fundamental to building truly Sustainable Water Infrastructure.

The Future of Water Control Structures

At FDE Hydro, we’re not just watching this evolution—we’re driving it. Our patented modular precast concrete technology, known as “French Dam” technology, represents a fundamental shift in how we construct and retrofit water control structures and hydroelectric dams.

This modular approach delivers tangible benefits that matter. Reduced construction time comes from prefabricating components off-site, which can slash project schedules dramatically. Significant cost reduction follows naturally when you minimize on-site labor and equipment needs—we’re talking about substantial savings that make projects financially viable. Improved durability is built into every engineered precast concrete component, ensuring structures can withstand harsh environmental conditions for decades.

Manufacturing components in a controlled factory environment also means better quality control. You get more reliable structures because every piece is built to exact specifications, not cobbled together on a muddy construction site. And perhaps most importantly, the modular nature of our components provides real flexibility—you can design with greater freedom and expand or modify structures later without starting from scratch.

We’re already deploying this innovative technology across North America, including the United States and Canada, as well as in Brazil and Europe. It’s a scalable and sustainable approach that works in diverse environments. We believe that leveraging advanced manufacturing techniques like modular precast concrete isn’t just about building better structures—it’s about open uping what could be The Biggest Untapped Solution to Climate Change is in the Water.

The future of water management demands structures that are smarter, stronger, and faster to build. That’s exactly what we’re delivering.

Conclusion

Throughout this guide, we’ve explored how water control structures serve as the backbone of modern water management, quietly performing essential work that touches nearly every aspect of our lives. These permanent installations manage the stage, discharge, and direction of water flow, supporting everything from productive farmland to thriving ecosystems.

We’ve seen how these structures lift water tables to reduce nutrient runoff in agricultural settings, regulate stormwater flows to protect communities from flooding, and create the precise conditions needed for fish spawning and wetland restoration. The diversity of available solutions—from simple flashboard risers with removable stoplogs to sophisticated gate systems and precisely calibrated weirs—demonstrates the adaptability of these technologies to meet specific site needs.

The technical details matter deeply. Selecting appropriate materials like corrosion-resistant PVC, robust steel, and durable concrete directly impacts how long a structure will serve its purpose. Design considerations such as proper pipe sizing, anti-seep collar installation, and adequate head capacity determine whether a structure will function effectively or require costly repairs. And perhaps most importantly, the commitment to regular maintenance—clearing debris, lubricating seals, and conducting semiannual inspections—separates structures that last decades from those that fail prematurely.

The future of water management is arriving faster than many realize. Climate change demands structures that can handle more extreme variability in rainfall and drought. Growing populations need solutions that work harder while costing less. At FDE Hydro, our modular precast concrete technology addresses these challenges head-on, cutting construction timelines and costs while delivering improved durability and quality control. This approach isn’t just about building better infrastructure—it’s about creating resilient systems that can adapt to whatever challenges tomorrow brings.

Water management has always required us to balance competing needs: economic development against environmental protection, immediate costs versus long-term value, human needs alongside ecosystem health. The most successful water control structures are those designed with this balance in mind, serving multiple purposes while remaining flexible enough to adapt as conditions change.

We invite you to explore how innovative solutions can transform your water management challenges into opportunities. Learn more about advanced hydropower solutions and find how modern technology is reshaping what’s possible in water infrastructure.