Why Project Costs Spiral Out of Control

Project cost reduction is the strategic process of decreasing expenses while maintaining or improving quality and scope. Here’s how to achieve it:

Top Strategies for Project Cost Reduction:

- Improve estimation accuracy – Involve your team and use historical data

- Establish clear baselines – Set firm scope, schedule, and cost benchmarks

- Control scope creep – Implement formal change control processes

- Optimize resources – Use capacity planning and strategic allocation

- Manage risks proactively – Identify and mitigate potential cost drivers early

- Leverage technology – Automate processes and improve collaboration

- Adopt modern methods – Use prefabrication and lean principles

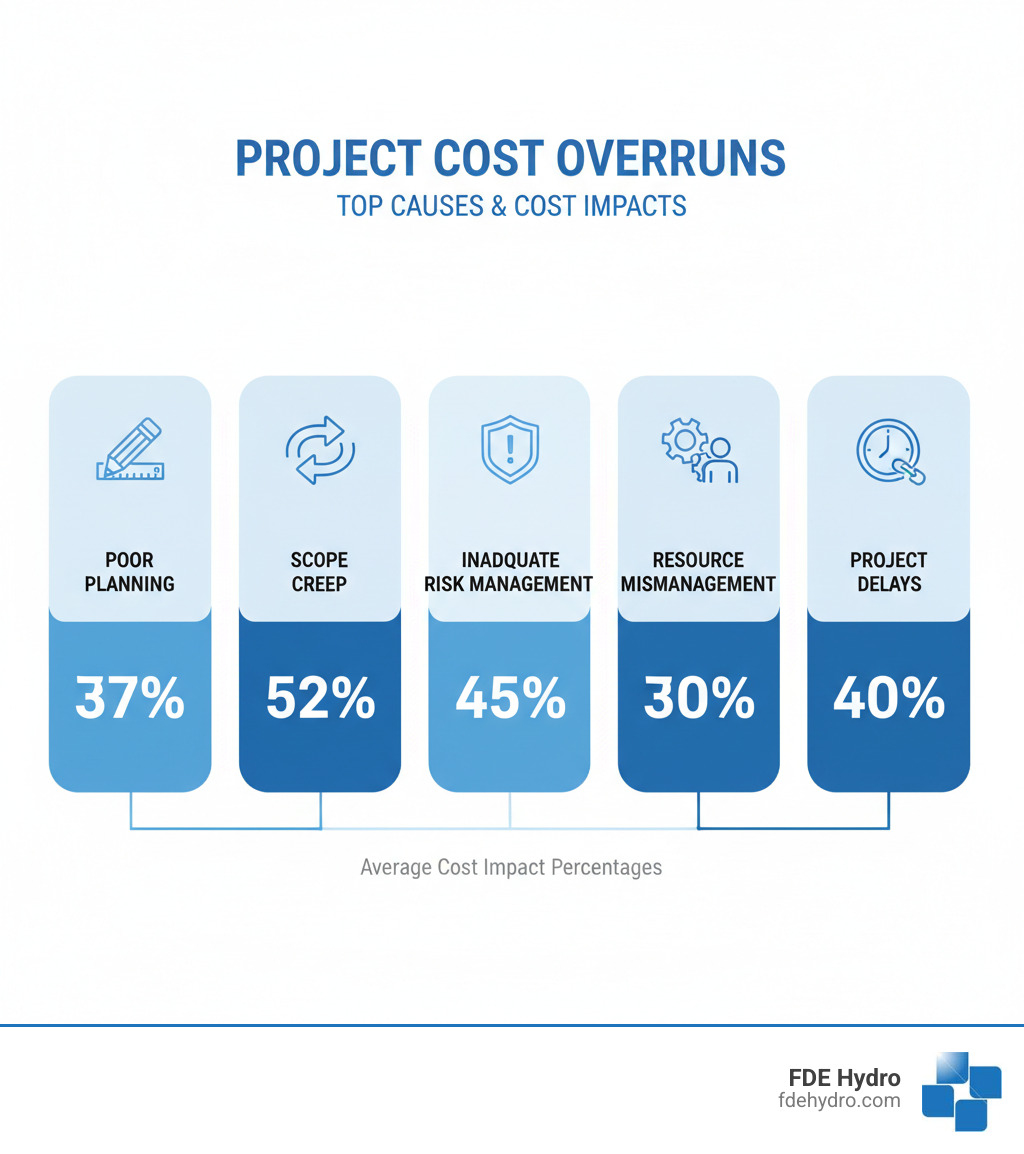

The harsh reality is that most projects exceed their budgets. Research shows 37% of projects fail due to poor planning, and 52% experience scope creep. These are fundamental breakdowns in cost control that can derail even the most promising infrastructure projects.

The construction industry faces unique pressures, where materials and equipment can represent over 70% of expenses. Combined with project delays and resource mismanagement, you have a perfect storm for budget overruns.

But cost reduction isn’t about cutting corners; it’s about working smarter. Cost-cutting is a reactive, temporary fix (like freezing hiring) that often damages a project’s long-term health. Cost reduction is a strategic, permanent improvement (like streamlining workflows) that strengthens it.

For large-scale infrastructure like hydropower systems, the stakes are even higher. Traditional methods involve enormous capital and long timelines, where every delay multiplies costs. As Bill French Sr., founder of FDE Hydro, I’ve spent five decades in heavy civil construction managing over $200M in annual projects. I’ve seen how strategic cost reduction separates success from failure. Through innovative approaches like modular precast construction, we’ve helped clients dramatically reduce capital costs and project timelines in hydropower development.

Project cost reduction terms to learn:

Master the Blueprint: Planning and Estimation for Cost Control

Effective project cost reduction begins long before work starts. It’s rooted in thorough planning—the blueprint phase that sets a project up for financial success.

1. Sharpen Your Estimates for Ultimate Accuracy in Project Cost Reduction

Inaccurate estimates are a primary cause of cost overruns. The problem often starts when estimates are made by people disconnected from the actual work. As Bryan Berthot notes, accuracy improves dramatically when the people doing the work are involved in estimating it.

By using bottom-up estimating, you tap into your team’s direct knowledge of task complexity and potential roadblocks. This not only improves accuracy but also increases commitment to the estimates. Supplement this expertise with historical data analysis. Reviewing past projects provides a data-driven reality check on how long tasks took and what resources they required, turning guesswork into informed projection.

Every estimate must be supported by a Basis of Estimate (BoE). This document is your financial roadmap, defining the scope, assumptions, exclusions, and methodology behind your numbers. For large-scale work like Hydropower Project Costs, a detailed BoE is essential for preventing budget-busting surprises.

2. Establish a Rock-Solid Project Baseline

With accurate estimates in hand, lock them into a project baseline. This fixed reference point is your project’s North Star, telling you if you’re on course. Without it, you’re navigating blind.

A complete baseline includes three parts: the scope baseline (the “what”), the schedule baseline (the “when”), and the cost baseline (the “how much”). Together, these components are essential for performance measurement.

Baselines are powerful tools for project cost reduction because they provide an early warning system. Regularly comparing actuals against the baseline highlights deviations immediately, letting you fix small problems before they escalate. For complex projects, we use a detailed Cost Breakdown Structure (CBS) to map every expense, from materials to labor. This granular approach, tied to our Means and Methods, ensures every step aligns with our financial goals.

A baseline isn’t rigid; it’s a standard for evaluating changes. When a change is proposed, you can assess its true cost impact against the baseline, enabling strategic decisions instead of reactive scrambling.

Execute with Precision: Managing Scope, Resources, and Risks

Even the best plan can fail during execution. To keep your project cost reduction efforts on track, you must master three critical elements: managing scope, optimizing resources, and preparing for risks.

3. Tame Scope Creep Before It Bites Your Budget

Scope creep—the slow addition of unplanned features or tasks—is a notorious budget killer. Research shows that 52% of projects experience scope creep, leading to cost overruns from added labor, materials, and timeline extensions.

The antidote is twofold. First, create crystal-clear documentation of all requirements and deliverables, agreed upon by all stakeholders. This becomes your project’s constitution. Second, implement a formal change control process. Every requested change, no matter how small, must be reviewed for its impact on cost, schedule, resources, and risk. This allows stakeholders to make informed decisions.

This process isn’t about saying “no”; it’s about being transparent about the true cost of changes. Regular stakeholder communication reinforces this discipline, turning clients into partners in protecting the project’s scope.

4. Optimize Your Resource Allocation

Poor resource management is a silent budget drain. Over-staffing, unnecessary overtime, and misuse of skilled personnel all lead to inefficiency and cost overruns.

Smart resource allocation starts with capacity planning to gain visibility into team availability and skills. From there, focus on:

- Strategic allocation: Match the right person to the right task. Don’t assign senior experts to routine work or junior members to critical challenges.

- Cross-training: Build a versatile team to reduce dependence on expensive external specialists and eliminate bottlenecks.

- Strategic outsourcing: Use external experts for limited, specialized tasks when it’s more cost-effective than hiring or training in-house.

Finally, engaged employees are more productive. As Business News Daily notes, valued employees work more efficiently and make fewer mistakes, directly supporting project cost reduction. For complex projects like Energy Infrastructure Development, optimizing resources is critical to finishing on time and within budget.

Leverage Modern Methods for Maximum Project Cost Reduction

To achieve maximum project cost reduction, you must move beyond traditional methods. This means anticipating problems, using technology, and rethinking the fundamentals of how projects are built.

5. Proactively Manage Risks to Avoid Costly Surprises

Projects rarely go exactly as planned. Proactive risk management prepares you for the inevitable surprises, turning potential crises into manageable issues. As the PMBOK Guide on risk management suggests, the goal is to decrease the impact of negative events and increase the impact of positive ones.

The process is straightforward:

- Identify risks early and continuously throughout the project.

- Analyze their likelihood and potential cost impact to prioritize your focus.

- Develop mitigation strategies to reduce the most significant threats, such as lining up backup suppliers or creating contingency plans.

This analysis informs your contingency funds—calculated buffers designed to absorb the cost of unforeseen events. For complex hydropower projects, this proactive approach is essential for financial viability, as discussed in Financing and Mitigating Risks.

6. Accept Technology and Automation

Construction has been slow to digitize, but technology is a powerful lever for project cost reduction. Modern project management software provides real-time visibility into budget utilization, allowing for immediate course correction.

Automation can free up teams from repetitive work; studies show up to 45% of tasks could be automated, and accounting automation alone can yield a 200% ROI in the first year. Additionally, optimizing software licenses can save up to 30%, according to Gartner.

Building Information Modeling (BIM) is transformative, creating a digital twin of the project to identify clashes and errors before construction begins. At FDE Hydro, technology is central to our modular approach. We use digital design and advanced manufacturing to produce high-precision components off-site, which is Why Precast Costs Less. This method reduces errors, cuts labor costs, and minimizes waste.

7. Innovate with Modern Construction and Manufacturing Techniques for Project Cost Reduction

The most dramatic project cost reduction comes from innovating how we build. Traditional methods are prone to expensive rework, which can consume 5% of a total project’s cost.

Lean manufacturing principles, which focus on eliminating waste, can cut costs by 5% to 20% in the first year. But the biggest game-changer is modular construction and prefabrication. By manufacturing components in a controlled factory setting and assembling them on-site, you gain immense benefits:

- Reduced on-site labor and weather delays.

- Improved quality control.

- Dramatically shorter construction times, saving on overhead.

- Lower material waste.

- Predictable costs locked in early.

Studies show this approach can save 10-20% on infrastructure projects. Our patented “French Dam” technology at FDE Hydro is a prime example. We manufacture modular precast components and use Rapid Installment of Module Precast Civil Infrastructure to build and retrofit dams with significantly lower costs and faster timelines. These Modular Construction Techniques deliver proven, real-world value.

Frequently Asked Questions about Project Cost Reduction

What’s the difference between cost reduction and cost-cutting?

This is a critical distinction. Cost-cutting is a reactive, short-term measure, like freezing hiring or delaying maintenance. It provides immediate savings but often harms quality, morale, and long-term project health.

Project cost reduction, on the other hand, is a strategic, long-term approach focused on improving efficiency. It involves optimizing processes, eliminating waste, and improving productivity to achieve permanent decreases in cost without sacrificing quality. One is a desperate fix; the other is a sustainable improvement.

What are the most common causes of project cost overruns?

The most frequent causes of budget overruns are preventable through better management. They include:

- Poor estimates: Unrealistic initial budgets set the project up for failure. As noted earlier, 37% of projects fail due to poor planning.

- Scope creep: Uncontrolled changes and additions cause costs to balloon. This affects 52% of projects.

- Ineffective risk management: Failing to plan for potential problems leaves the budget exposed to costly surprises.

- Project delays: Every delay extends costs for labor, equipment, and overhead.

- Poor resource management: Inefficient use of personnel and equipment leads to waste and higher expenses.

Addressing these issues is the foundation of effective project cost reduction.

How can technology help in reducing project costs?

Technology is a powerful tool for project cost reduction by improving efficiency and providing critical insights. Key benefits include:

- Improved Accuracy: Tools like Building Information Modeling (BIM) and analytics software lead to more precise estimates and help detect design clashes before they become expensive on-site rework.

- Automation: Automating repetitive tasks (up to 45% of them, according to research) frees up human resources for higher-value work. Accounting automation alone can deliver a 200% ROI in the first year.

- Real-Time Data: Modern software provides instant visibility into project spending, allowing managers to address budget deviations immediately instead of waiting for month-end reports.

- Better Collaboration: Cloud-based platforms ensure all stakeholders are working from the same, up-to-date information, which reduces miscommunication and errors.

At FDE Hydro, technology is integral to our modular approach and is a key reason Why Precast Costs Less. By leveraging digital design and advanced manufacturing, we achieve sustainable cost savings.

Conclusion: Building a Culture of Cost-Consciousness

The strategies outlined in this guide provide a powerful toolkit for changing your project’s financial health. However, true project cost reduction is more than a checklist; it’s a culture of continuous improvement that should permeate every decision in your organization.

When everyone on your team understands how their choices impact the bottom line, they become partners in efficiency. This mindset isn’t about being cheap; it’s about being smart, resourceful, and deliberate with every dollar spent.

At FDE Hydro, this philosophy is at our core. Our innovative modular precast concrete technology, the “French Dam,” was born from a relentless focus on building better, faster, and more cost-effectively. By prefabricating components and rapidly assembling them on-site, we have dramatically cut construction timelines and costs for clients across North America, Brazil, and Europe. The result is predictable costs, faster delivery, and exceptional quality—turning cost-consciousness into a competitive advantage.

So where do you go from here? Start by implementing one strategy tomorrow. Formalize your change control process, invest in better software, or refine your estimation process with your team. Small, consistent steps compound into significant savings over time.

Every dollar saved through strategic project cost reduction is a dollar that can be reinvested in innovation, people, and growth. It strengthens your competitive position and builds a more resilient future.

Ready to see how modern construction techniques can transform your next hydropower project? Learn more about our innovative dam solutions and find how we’re helping clients build smarter, faster, and more economically.