Precast Concrete Application in Related Industries

Precast Models

Precast modules can be prefabricated with your choice of molds that create the desired architectural finish to your project. Customize the appearance of the modules according to region specific attributes, add features to the facade, make it modern.

Cast-in-Place Vs. Precast

Benefits of Precast

Cast-in-Place

Concrete poured on site presents costly risks to projects. The final product may be impacted by weather fluctuations, speed of curing, lack of vibration, pouring adversities and more.

Precast Concrete

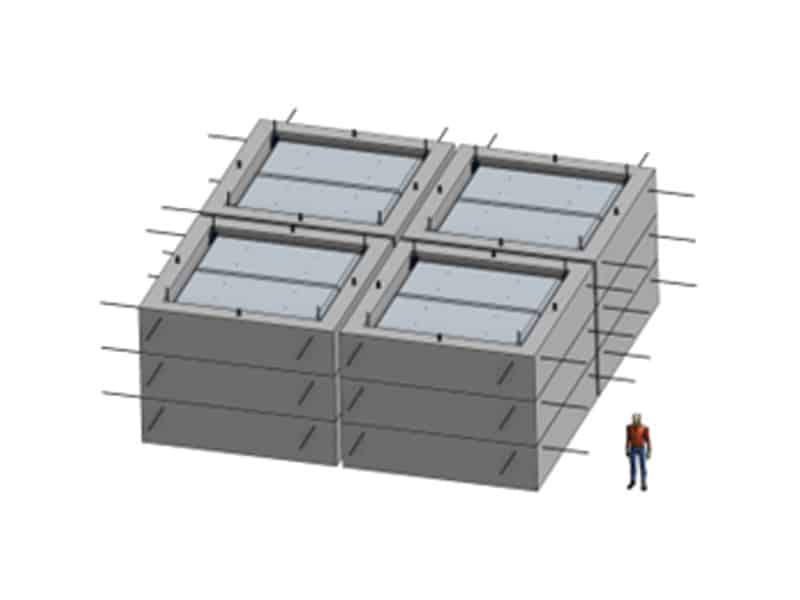

Precast concrete modules eliminate most risks associated with cast-in-place. The quality control implemented in the manufacturing process ensures engineered high strength mixing batches, fast curing process, solid finish without defects, serialized production according to schedule activities, inspection and acceptance of each module before deployment, and 100+ years lifespan.

We Are the Leader of Modular Civil Water Infrastructure

IP Portfolio

With an impressive portfolio of over 40 patents in the hydropower industry, FDE Hydro™ stands at the forefront of innovation in modular precast technology. Dominating market segments across North America, Europe, and Brazil, our cutting-edge solutions have revolutionized the way hydropower projects are designed and executed. Our patented advancements ensure unparalleled efficiency, sustainability, and durability in every project, setting new standards in the industry. Join us as we lead the change towards a more sustainable and resilient future with our groundbreaking modular precast solutions.

Historic Uses of Precast

Since its inception in the early 20th century, precast concrete has revolutionized the construction industry with its versatility and reliability. Initially employed in the construction of bridges and buildings, it quickly proved its worth in a variety of applications due to its durability and efficiency. Over the decades, precast concrete has been used in everything from seismic-resistant structures in earthquake-prone areas to hurricane-proof buildings in storm-hit regions, as well as flood-resistant infrastructure and fireproof constructions. Its enduring legacy highlights its pivotal role in creating resilient and sustainable structures worldwide.

Gov. Mario M. Cuomo Bridge/Tappan Zee Bridge, NY | SoFi Stadium, CA | Harry W. Nice Memorial/Senator Thomas “Mac” Middleton Bridge

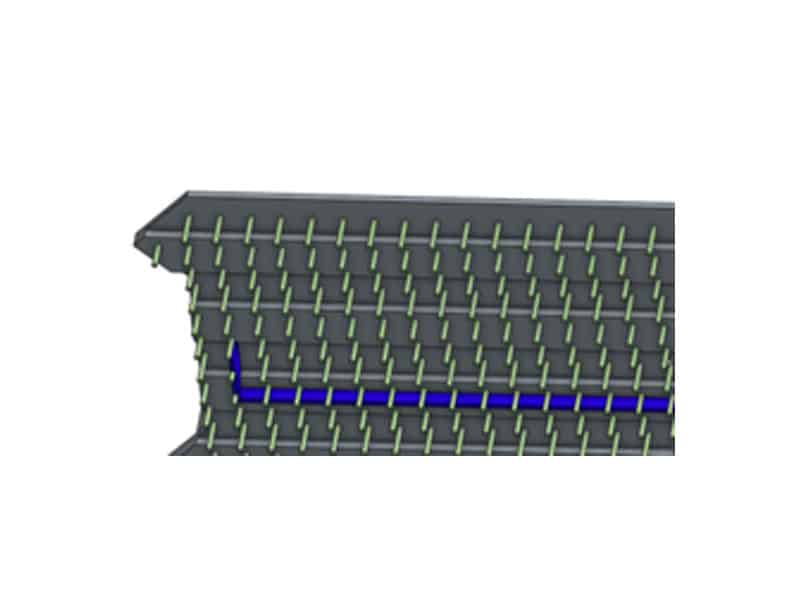

Precast Model

Any Size. Any Shape.

Our solutions are adaptable according to your project specifications. Designed by licensed engineers using structural, geotechnical, hydrological and other reports the modules are optimized to maximize the lifespan of your civil project while minimizing project risk and costs. Means and methods ensure fast installation, quality control assurance and safer environment – in and out of site quicker than compared to cast-in-place.

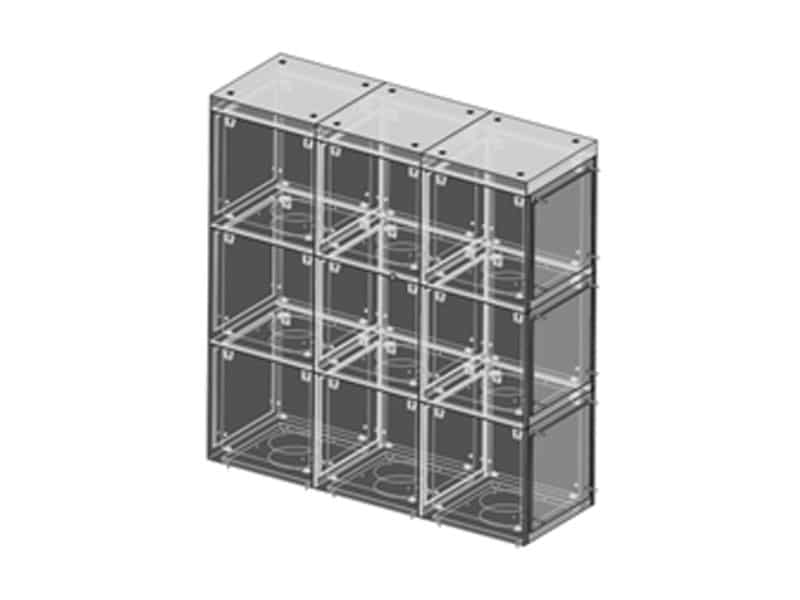

Precast model: Step-By-Step

Precast modules are manufactured in a quality-controlled environment, staged on project location and ready for assembly. All modules are serialized enabling a rapidly deployable system, optimizing predictable and scalable production rates, and lowering overall project risk.

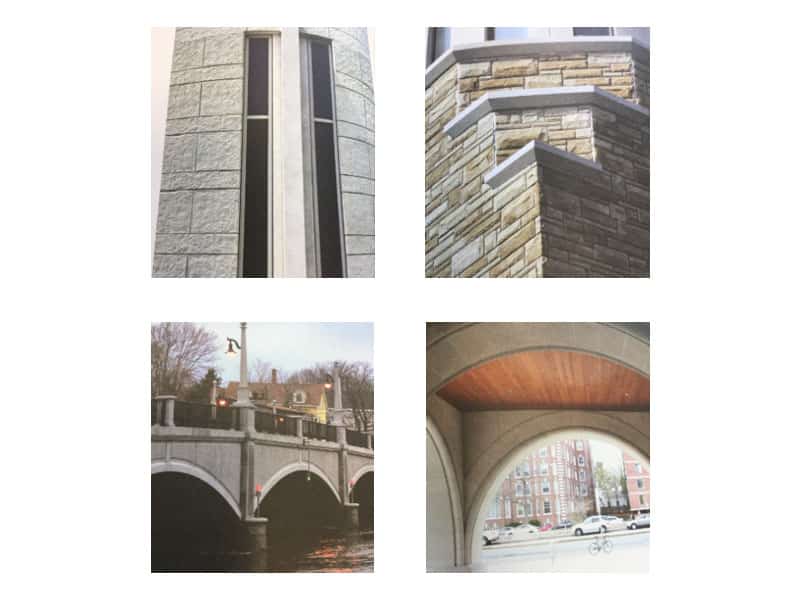

Exterior Finishes

Multiple Exterior Finishes Based on your Environment

Precast modules can be prefabricated with your choice of molds that create the desired architectural finish to your project. Customize the appearance of the modules according to region specific attributes, add features to the facade, make it modern.