Why Precast Concrete Technology Matters Now

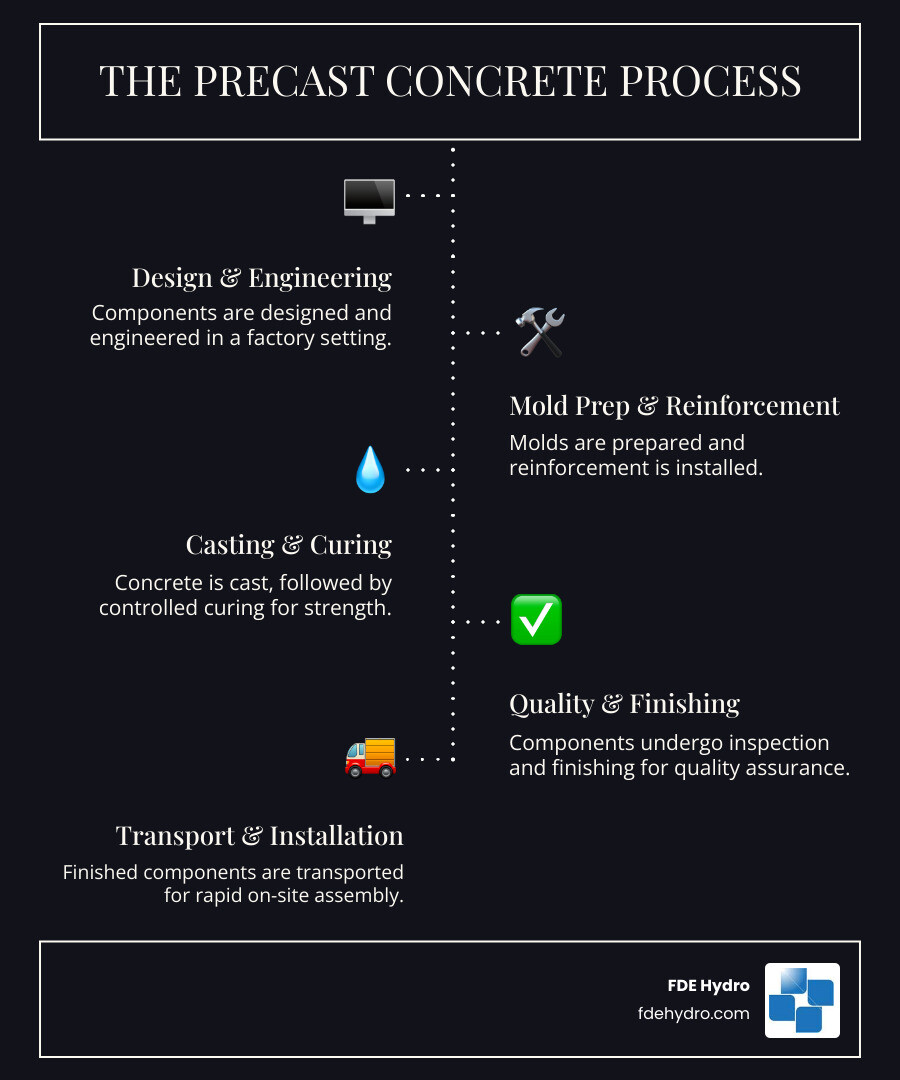

Precast concrete technology is an industrialized construction method that is changing how we build. Instead of pouring concrete on-site, components are cast in a controlled factory environment, cured to full strength, and then transported to the jobsite for rapid assembly.

Key Benefits of Precast Concrete Technology:

- Speed: Erect one floor of a multi-story building in as little as one week.

- Quality: Factory conditions ensure superior strength and durability, with design lifespans of 50-100 years.

- Cost: Uses less water, cement, steel, and labor than cast-in-place methods.

- Sustainability: Creates a smaller carbon footprint and reduces on-site waste.

- Safety: Moves most construction work from hazardous jobsites to controlled factory floors.

The global precast concrete market is projected to reach $168.17 billion by 2026, driven by the demand for faster, more cost-effective construction. This technology’s power comes from combining industrialized processes, advanced materials, and digital tools like Building Information Modeling (BIM) for unprecedented precision and efficiency.

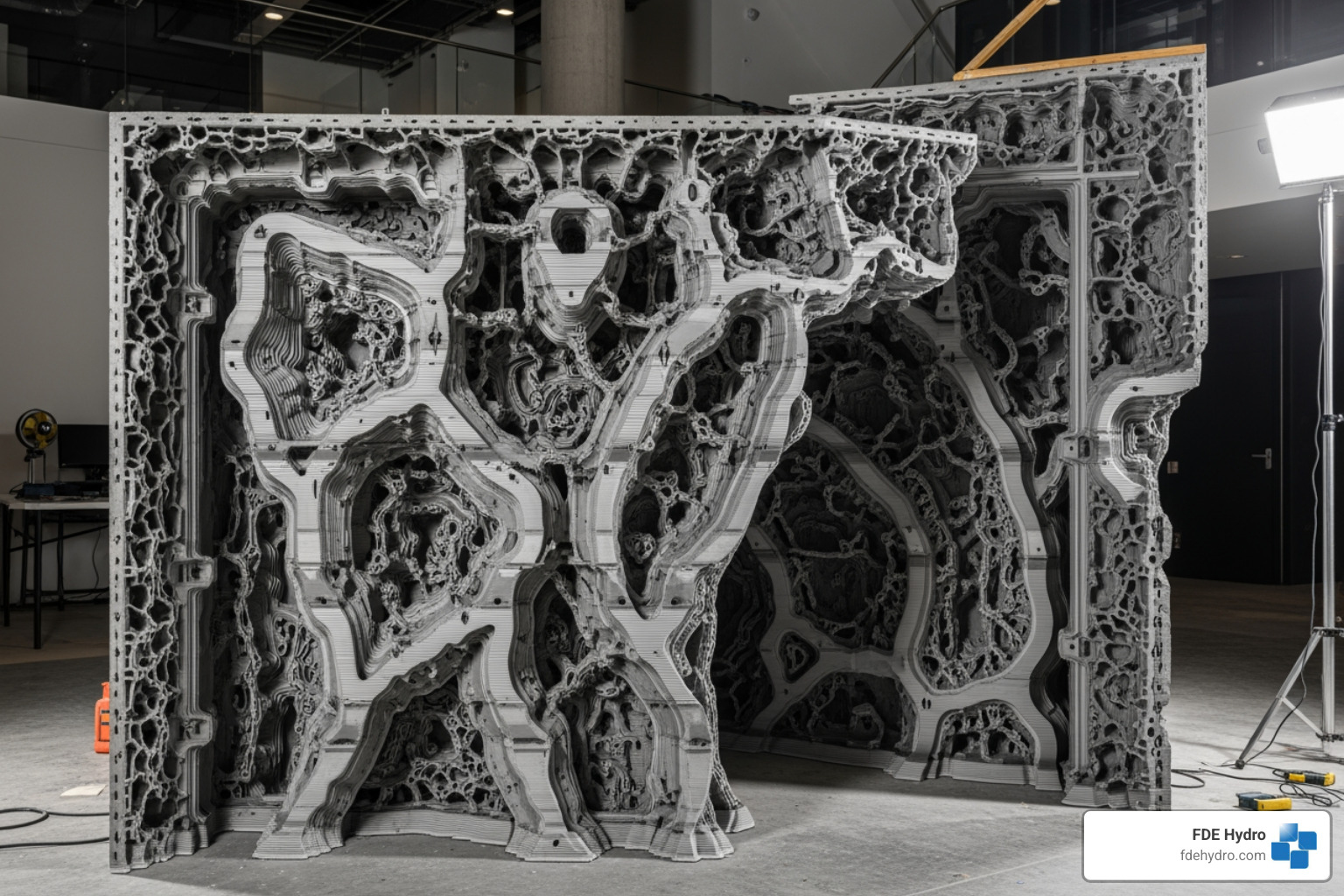

Modern precast has evolved far beyond simple blocks to include smart concrete with embedded sensors, 3D-printed formwork, and high-performance insulated panels. These innovations offer solutions to longstanding challenges in critical infrastructure, especially for industries like hydropower and water control systems.

I’m Bill French Sr., Founder and CEO of FDE Hydro. Over five decades in heavy civil construction, I’ve seen precast evolve from basic components to sophisticated modular systems. My company now holds patents in the US, Canada, Europe, and Brazil for modular precast solutions that dramatically reduce construction time and costs while benefiting the environment.

The Core Advantages: Why Precast is Reshaping Construction

Modern construction faces intense pressure to be faster, better, and more cost-effective. Precast concrete technology meets these demands in ways traditional methods cannot, representing a fundamental shift in how we build.

By manufacturing concrete components in a factory, everything changes. Consistent temperature, regulated humidity, and precise mixes result in denser, stronger concrete. This factory advantage extends beyond quality. While site preparation occurs, components are manufactured simultaneously, dramatically accelerating project timelines. Less on-site labor means lower costs and fewer delays, improving ROI.

Safety is also significantly improved. Moving labor-intensive work from hazardous jobsites to controlled factory floors protects workers from falls, weather, and other dangers. The finished product is also safer, offering excellent fire resistance and durability against impacts.

Surprisingly, precast concrete technology offers remarkable aesthetic flexibility. Modern techniques enable virtually any color, texture, or finish. Formliners create intricate patterns, and graphic concrete can embed photographic images into facades. For a detailed look at the cost advantages, explore our insights on Why Precast Cost Less.

How does precast stack up against traditional cast-in-place concrete? Here’s a clear comparison:

| Feature | Precast Concrete | Cast-in-Place Concrete |

|---|---|---|

| Cost | Lower overall cost due to less labor, faster completion, and less waste. | Higher labor costs and risk of overruns from weather and delays. |

| Quality | Superior and consistent due to controlled factory environment and rigorous testing. | Variable quality dependent on site conditions, weather, and skill. |

| Construction Time | Significantly faster due to off-site manufacturing and rapid on-site assembly. | Slower due to sequential on-site forming, pouring, and curing. |

| Sustainability | Lower carbon footprint with less water, cement, and on-site waste. | Higher resource use and on-site waste generation. |

| Durability | Exceptional, with a design life of 50-100+ years. Resistant to mold and harsh weather. | Good, but can be compromised by inconsistent quality and curing. |

| Safety | Safer, with most work performed in a controlled factory, reducing on-site hazards. | Higher on-site risk from formwork, pouring at heights, and weather. |

| Aesthetics | Highly flexible with a wide range of colors, textures, and custom shapes. | Limited by on-site finishing capabilities; consistency is a challenge. |

Best Speed and Efficiency

Speed changes everything in construction. Precast concrete technology delivers this advantage through industrialized manufacturing. By requiring fewer workers on-site, precast projects can proceed even when skilled labor is scarce in the US, Canada, and Europe.

Parallel processing is key. While foundation work happens at the site, structural components are manufactured at the plant. This just-in-time delivery means components arrive cured and ready for installation, eliminating weather delays during the critical setting period. The results are dramatic: one floor of a multi-story building can be erected in a week, and highway repairs can be completed overnight, minimizing traffic disruption.

Superior Quality and Durability

A building that lasts 100 years is a better investment than one needing repairs in 30. Precast concrete technology excels here. The controlled factory environment—with consistent temperature, humidity, and precise mix designs—is impossible to replicate on a jobsite. This produces high-strength concrete that is denser and more uniform.

The result is exceptional longevity, with design lives of 50 to 100 years, and sometimes up to 200. Precast concrete’s dense composition resists moisture, preventing mold and mildew, and it naturally resists fire and impact. For more background, the article on Precast concrete | Reinforced, Structural & Prefabricated provides excellent technical detail.

Aesthetic and Design Flexibility

Concrete doesn’t have to be plain. Modern precast concrete technology offers architects unprecedented design freedom. Architectural precast panels can achieve nearly any appearance, from smooth and polished to textured with exposed aggregate. Reusable molds make complex shapes and patterns practical and cost-effective.

Techniques like formliners can replicate the look of natural stone or brick, while graphic concrete can embed photographic images into facades. This design freedom allows buildings to be both functional and beautiful, changing urban landscapes from New York to Europe.

A Spectrum of Solutions: Types and Applications of Precast Concrete

Precast concrete technology is incredibly versatile, found in everything from skyscraper skeletons to the bridges we drive on. It’s not a one-size-fits-all material; it adapts to the specific challenges of a project.

The same technology that creates architectural panels for an office in New York can produce massive bridge girders. We use precast for structural components, architectural elements, and infrastructure products that keep cities running.

At FDE Hydro, we’ve adapted this versatility for our specialized modular precast systems for hydropower and water control. The ability to be rapidly installed changes the game for civil infrastructure. You can learn more in our article on Rapid Installment of Module Precast Civil Infrastructure.

Structural and Architectural Systems

For buildings, precast concrete technology offers a toolkit combining structural strength with architectural beauty.

- Columns and Beams: These factory-made elements form the skeleton of countless buildings, manufactured to exact specifications for consistent, high load-bearing capacity.

- Hollow-Core Slabs: Lightweight yet incredibly strong, their hollow channels reduce weight and provide conduits for electrical and plumbing systems.

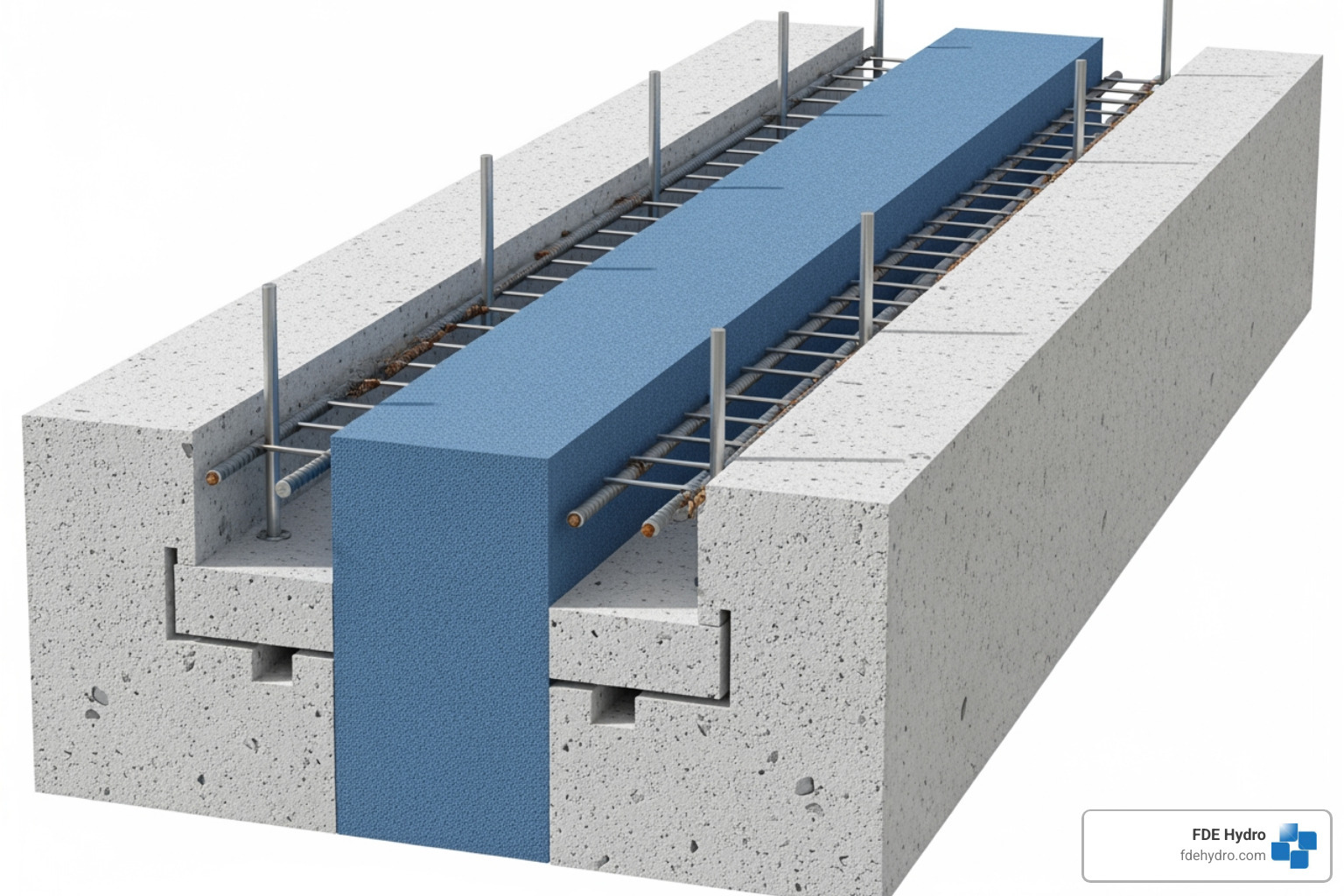

- Wall Panels: Available as solid structural panels, architectural cladding, or insulated sandwich panels, they offer thermal performance and noise control while enabling rapid enclosure of a structure.

- Total Precast Systems: For maximum speed, entire buildings—floors, walls, beams, and stairs—are constructed from precast elements, ensuring consistent quality.

- Cladding and Facades: These exterior walls are opportunities for creative expression, customized with virtually any color, texture, or pattern to create unique, durable, and energy-efficient building envelopes.

The Canadian Precast Concrete Institute showcases the wide range of Products and Systems – Canadian Precast Concrete Institute available for building applications.

Civil Infrastructure and Transportation

Precast proves its worth in civil infrastructure, where durability and speed are paramount.

- Bridge Construction: Precast girders, deck panels, and abutments are central to Accelerated Bridge Construction (ABC), which minimizes traffic disruption. We’ve documented examples like this National Example of Rapid Bridge Construction Using Modular Precast Elements.

- Culverts and Walls: Precast box culverts for drainage and retaining walls for earth retention are installed quickly with less site disruption.

- Precast Concrete Pavement (PCP): These durable panels are installed overnight and designed to last over 40 years, making them invaluable for busy highways in California, New York, and Kansas.

- Water Management: Stormwater systems rely on robust precast catch basins, manholes, and pipes.

- Hydropower and Water Control: At FDE Hydro, our patented “French Dam” technology is a specialized evolution of precast. We build and retrofit hydroelectric dams and water control systems faster and more cost-effectively across North America, Brazil, and Europe.

The Technological Leap: How Innovation is Advancing Precast Concrete Technology

Today’s precast concrete technology would seem like science fiction to builders just twenty years ago. We’ve moved beyond simple molds to integrate digital intelligence, robotics, and advanced materials science, creating solutions that are smarter, faster, and more precise.

This marriage of concrete expertise with cutting-edge technology is making projects possible that were once prohibitively expensive or time-consuming.

Digital Integration: BIM and Digital Twins

The digital revolution has transformed the precast plant. Building Information Modeling (BIM) acts as a central digital blueprint, allowing teams to collaborate in real-time. At FDE Hydro, BIM lets us model every detail with precision, spot potential clashes, and coordinate with architects and engineers from New York to Brazil. This reduces on-site surprises and smooths project delivery.

Digital twin technology takes this further by creating a virtual replica of a manufacturing process or a finished structure. This allows us to monitor concrete curing, simulate production workflows, and track components from factory to site. This level of visibility helps us create more accurate Precast Models and deliver projects with unprecedented predictability.

Key Innovations in precast concrete technology

Breakthroughs are happening in the concrete itself and the molds that shape it.

Smart concrete, with embedded sensors and IoT devices, can monitor its own health. These sensors track structural integrity, temperature, and moisture, providing real-time feedback that is invaluable for critical infrastructure like bridges and dams in Canada, Europe, and the United States.

3D printing and additive manufacturing are revolutionizing custom formwork. While not yet used for entire girders, 3D printing excels at producing complex, custom molds for intricate architectural details. This approach reduces waste and speeds up the production of specialized components, offering geometric freedom for unique projects in places like California.

High-Performance Materials and Components

The concrete mix itself has evolved. Modern precast concrete technology incorporates advanced materials for superior performance.

- High-performance insulated panels sandwich insulation between concrete layers, creating structural, thermally efficient walls with R-values of R-28.2 or higher. This cuts energy costs in climates from Canadian winters to Brazilian summers.

- Advanced finishing techniques can polish concrete to a mirror shine or texture it to mimic stone or wood, improving both aesthetics and durability.

- Lightweight concrete mixes make components easier and cheaper to transport and install without sacrificing strength.

- Supplementary cementitious materials (SCMs) like fly ash and slag improve strength and durability while reducing the cement needed, lowering the carbon footprint.

- Ultra-High Performance Concrete (UHPC) achieves compressive strengths over 9,000 psi in just 10 hours, making it ideal for creating strong connections in rapid bridge construction.

Explore how these materials come together in our page on Modular Construction Techniques.

Building a Greener Future: Sustainability in Precast Concrete

The construction industry must consider its environmental consequences. Precast concrete technology offers a path forward that reduces waste, conserves resources, and creates structures that perform efficiently for generations.

What makes precast sustainable is the entire approach, from the factory to the building’s full lifecycle. This matters everywhere, from Canada to Europe, and organizations like Sustainable Precast are advancing these green practices. At FDE Hydro, our modular precast systems for hydropower build dams faster and with less environmental disruption.

Resource Efficiency and Waste Reduction

Unlike a typical construction site, a precast factory is a model of efficiency. Mix designs are optimized to use the exact amount of water, cement, and aggregates. This precision means precast uses significantly less water, cement, and steel than cast-in-place construction.

Modern precast plants also operate as recycling centers. Excess concrete is reused as aggregate, water is recirculated, and steel molds are reused hundreds of times. When components arrive on-site, they are ready to install, eliminating the waste associated with on-site concrete work.

An exciting innovation is CO2 mineralization, where recycled carbon dioxide is injected into fresh concrete. The CO2 becomes a permanent mineral, sequestering carbon and improving strength, which allows for even less cement. This technology is gaining traction across North America and Europe.

Energy Performance and Building Lifecycle

A building’s environmental impact is dominated by its operational energy use. Precast concrete technology addresses this through its inherent thermal mass, which absorbs and releases heat to moderate indoor temperatures, reducing heating and cooling costs.

Insulated sandwich panels take this further, creating highly efficient building envelopes with R-values up to R-28.2. This can cut heating and cooling costs by 30% or more in a building in New York or California, reducing greenhouse gas emissions for decades.

Durability is also a key sustainability factor. Precast structures last 50 to 100 years with minimal maintenance, conserving the resources that would be spent on repeated repairs and reconstruction. At the end of its life, a precast structure can often be deconstructed and its components reused, supporting a circular economy. At FDE Hydro, we apply these principles to create hydropower infrastructure that generates clean energy for a century or more.

From Past to Future: The Evolution and Trajectory of Precast

The story of precast concrete technology is one of constant evolution, from ancient building techniques to today’s digital manufacturing.

A Brief History of Prefabrication

The idea of off-site construction is ancient. The Romans, masters of engineering, used standardized concrete elements for aqueducts and tunnels, many of which still stand. The principles they used were the foundation for modern precast.

Modern precast concrete technology emerged in the early 1900s. In 1905, Liverpool, England, constructed the first precast panelled buildings, proving the method’s potential for rapid assembly. You can explore more about prefabrication’s evolution in Prefabricated and Modular Architecture: Aligning Design with Manufacture and Assembly. The post-war era of the 1950s saw further refinement, as housing shortages drove innovation in manufacturing and quality standards for reinforced concrete | building material, establishing precast as a reliable, scalable construction method across Europe and North America.

Future Trends in precast concrete technology

The future of precast concrete technology is smart, sustainable, and digitally integrated. We are already seeing these trends emerge.

- Automation and AI: Robotics are handling repetitive tasks like rebar placement and pouring, improving safety and consistency in plants across the US, Canada, and Brazil. AI algorithms monitor curing in real-time to ensure optimal strength and spot potential defects.

- Renewable Energy Integration: Precast panels are being designed with embedded solar cells or thermal systems that work with geothermal energy, turning passive building materials into active energy systems.

- Circular Economy: With lifespans of 50-100 years, precast is already durable. The next step is designing for deconstruction, allowing components to be repurposed rather than demolished. This is crucial as we tackle Aging Infrastructure Being Replaced With Next Generation Civil Solutions.

At FDE Hydro, our patented “French Dam” system embodies this future, combining concrete’s strength with modern innovation to revolutionize hydroelectric projects.

Conclusion

We’ve journeyed through precast concrete technology, from its core advantages to the innovations shaping its future. This isn’t just another building method; it’s a fundamental shift in how we approach construction, addressing the critical challenges of speed, cost, quality, and sustainability all at once.

The controlled factory environment delivers superior quality, while parallel processing allows projects to be completed in a fraction of the time. Aesthetically flexible and inherently durable, precast is a genuinely sustainable choice that reduces waste and lowers energy consumption over a building’s long lifespan.

As the global precast market grows toward $168.17 billion by 2026, its applications are expanding, from highways assembled overnight to high-rises erected in record time. At FDE Hydro, we are at the forefront of this evolution. Our patented “French Dam” modular precast technology applies these principles to hydropower and water control systems, building and retrofitting critical infrastructure faster and more affordably for communities in North America, Brazil, and Europe.

The future of construction is here, and it’s built on a foundation of precast concrete. If you’re interested in seeing how these innovations can transform critical infrastructure projects, we invite you to Explore advanced precast solutions for hydropower infrastructure with us.