The Construction Revolution You Need to Know About

Modular construction techniques are revolutionizing the building industry by shifting most of the work from chaotic job sites into controlled factory environments. Instead of traditional on-site assembly, this method involves manufacturing complete building sections—like entire rooms or wall panels—in a factory, then transporting and assembling them at the project location.

This approach isn’t new; a prefabricated home was shipped from London to Australia in the 1830s. But today’s modular construction is a convergence of manufacturing precision with construction at scale, powered by digital tools like Building Information Modeling (BIM).

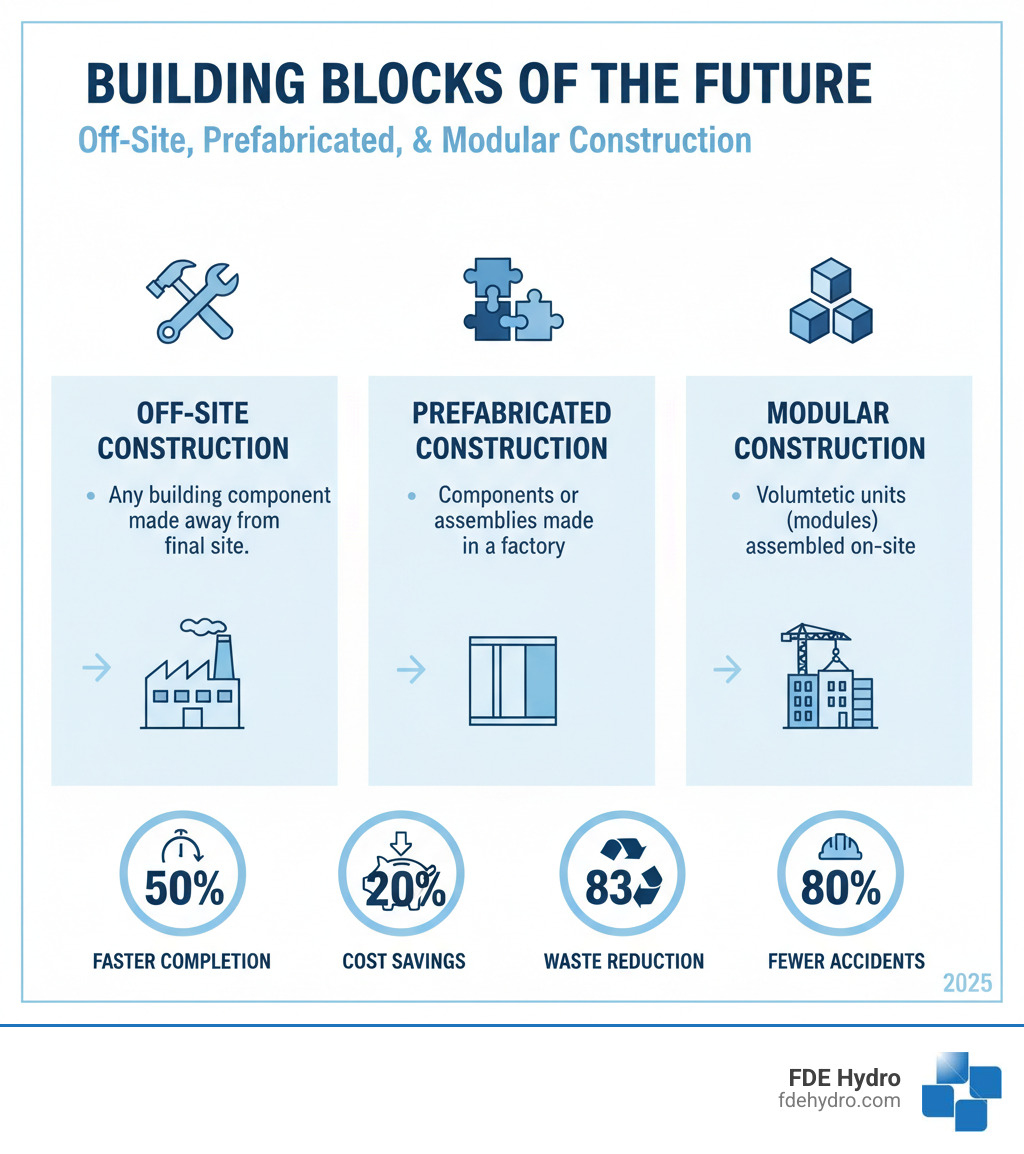

Why does this matter? The construction industry faces immense pressure. Projects routinely run over budget and behind schedule, the sector lags in digitization, and it produces nearly 40% of global carbon emissions. Modular construction addresses these challenges directly. Research shows it can reduce project timelines by 30-50%, cut costs by up to 20%, and slash material waste by 83%. Factory environments also improve quality control and reduce on-site accidents by over 80%.

For decision-makers managing large-scale infrastructure, modular approaches offer reduced capital expenditure, accelerated delivery, and minimized financial risk. I’m Bill French, Sr., Founder and CEO of FDE Hydro™, where we’ve pioneered modular construction techniques for the hydropower industry. My five decades in civil construction have convinced me that the future belongs to those who accept manufacturing principles in construction.

Defining the Terms: Modular vs. Prefabricated vs. Off-Site

While often used interchangeably, these terms have distinct meanings:

- Off-site construction is the broadest term, covering any component made away from the final building site.

- Prefabricated construction is a subset of off-site, involving specific components like wall panels or roof trusses made in a factory before transport.

- Modular construction is a specific type of prefabrication. It involves creating complete, self-contained units or “modules” in a factory—often with all interior finishes, plumbing, and electrical systems. Think of them as giant Lego blocks. All modular construction is prefabricated and off-site, but not all off-site or prefabricated construction is modular.

Why is Modular Construction Gaining Momentum?

The construction industry’s slow pace of innovation has created a productivity gap, leading to project delays and waste. This stagnation, combined with global demand for faster and more sustainable solutions, has fueled the rise of modular construction techniques. Key drivers include:

- Addressing Housing Shortages: Modular methods accelerate project timelines, offering a viable solution to the urgent need for affordable housing.

- Sustainability Goals: By inherently reducing waste and embodied carbon, modular construction aligns with green building principles.

- Technological Advancements: Digital tools like BIM and automation have revolutionized module design and production, ensuring higher quality and greater flexibility.

- Economic Demands: The potential for up to 20% cost savings and 50% shorter timelines makes modular construction economically attractive.

- Labor Shortages: Factory-based work helps mitigate skilled labor shortages by offering safer, more controlled working conditions.

An In-Depth Look at Modular Construction Techniques

Understanding how modular construction techniques work reveals their transformative potential. The core concept is to manufacture building components in a factory for rapid on-site assembly. This approach offers surprising variety and flexibility.

The beauty of modular construction lies in its flexibility. Projects can use volumetric modules (complete 3D rooms), panelized systems (flat 2D components), or hybrid approaches that combine both. The choice depends on project needs, and materials can range from steel and wood frames to durable concrete modules. Our work at FDE Hydro with Precast Models shows how precision-engineered concrete can deliver infrastructure that lasts for generations.

Volumetric Modular Construction (3D Modules)

Volumetric construction involves building complete, room-sized 3D units in a factory—often including fixtures, flooring, and paint. These finished modules are then transported, lifted into place, and connected on-site. This is the ultimate “plug and play” approach to building.

Because these modules are engineered to withstand transportation and craning, they are often stronger than traditionally built structures. Once positioned on the foundation, they are connected to each other and to utilities, allowing a building to take shape with incredible speed. This method is ideal for repetitive units found in hotels, multi-family housing, and student dormitories. Our Rapid Installment of Module Precast Civil Infrastructure projects apply these same principles to revolutionize large-scale infrastructure development.

Panelized and Sub-Assembly Systems (2D Modules)

For projects that don’t require complete room modules, panelized systems offer the efficiency of factory production for a building’s shell. Factory-produced wall panels, floor sections, and roof components arrive at the site ready for rapid assembly, often with windows, insulation, and cladding already installed.

Sophisticated options include Structural Insulated Panels (SIPs) for high thermal performance and precast concrete panels for durability. The real magic, however, often lies in specialized sub-assemblies. A factory-built bathroom pod arrives complete with all fixtures, plumbing, and finishes. Kitchen units and pre-assembled mechanical racks also streamline on-site work by allowing specialized trades to operate in a controlled environment where quality is easier to ensure.

This approach is exemplified by our Modular Sea Wall Systems, which use panelized precast components to create resilient coastal infrastructure. Panelized systems can be up to 70% complete before reaching the site, delivering significant time and cost savings.

Permanent vs. Relocatable Modular Construction

A common misconception is that modular construction is only for temporary buildings. In reality, it excels for both permanent and relocatable structures.

Permanent Modular Construction (PMC) creates buildings designed for long-term use, meeting or exceeding all building codes just like traditional construction. The final appearance is indistinguishable from a site-built structure; the only difference is the efficient process. Our patented “French Dam” system is an example of permanent modular infrastructure, engineered with precast components designed to last for generations.

Relocatable Buildings (RBs) are designed for disassembly, transport, and reuse. This makes them ideal for construction site offices, temporary classrooms, and disaster relief housing. RBs embody circular economy principles, serving multiple purposes over their lifespan rather than being demolished. Both approaches showcase the adaptability of modular construction, offering solutions for permanent infrastructure and flexible, temporary spaces.

The Transformative Benefits of Modular Construction

The shift to modular construction techniques is about building better. By addressing the inefficiencies of traditional methods, modular construction delivers measurable improvements in speed, cost, quality, safety, and sustainability.

Contrast a chaotic, weather-exposed construction site with a clean, organized factory floor. The difference is transformative, offering solutions to problems that have plagued the industry for generations.

Speed, Cost, and Quality Advantages

Time is money, and modular construction techniques save both. By building modules in a factory while site preparation happens simultaneously, projects can finish 20% to 50% faster than traditional builds. This parallel processing is the key to accelerated timelines.

This speed leads to significant financial benefits. McKinsey’s research shows modular construction can deliver up to 20% in total cost savings, with potential annual savings of $22 billion in the U.S. and Europe. Savings come from reduced labor costs, fewer weather delays, and faster occupancy. At FDE Hydro™, our analysis shows Why Precast Cost Less for infrastructure projects.

Quality control is another game-changer. With up to 90% of construction occurring in a factory, variables like weather are eliminated. Every module undergoes rigorous quality checks, reducing rework and ensuring consistent standards. This reliability turns hopeful estimates into dependable timelines.

Key Benefits of Adopting Modular Construction Techniques for Sustainability

Construction accounts for nearly 40% of global CO2 emissions and a third of the world’s waste. Modular construction techniques directly address this environmental impact.

In a factory, material waste can drop by up to 90%. This is due to precise cutting, efficient inventory management, and immediate recycling of excess materials. The WRAP Report on Modern Methods of Construction documents these benefits extensively.

Embodied carbon—emissions from manufacturing and installing materials—also decreases significantly. This stems from efficient material use and reduced transportation. Furthermore, shifting most activity off-site minimizes local environmental disruption, including noise, dust, and traffic.

Modular construction also accepts circular economy principles. Relocatable modules can be disassembled and reused, giving building components multiple lifespans and changing them from disposable structures into long-term assets.

Enhancing Safety and Minimizing Community Disruption

Construction is one of the most dangerous industries. By moving up to 80% of construction activity into controlled factory environments, modular construction techniques dramatically improve worker safety. Reportable accidents can drop by over 80%.

Factory workers operate in well-lit, climate-controlled spaces, eliminating many risks common to outdoor job sites. This safer environment also helps attract a more diverse workforce, addressing labor shortages.

Communities benefit from less disruption. With fewer deliveries and a shorter on-site construction phase, there is less traffic, noise, and pollution. This is critical for projects in dense urban areas or sensitive locations. Our work replacing aging infrastructure with next generation civil solutions relies on this minimal-impact approach to maintain public support while delivering essential upgrades.

Navigating the Challenges and Key Considerations

While the benefits are substantial, modular construction techniques require a different approach to planning and execution. Successfully implementing modular methods means anticipating and managing a unique set of challenges related to logistics, design, and industry adaptation.

Executing projects like A National Example of Rapid Bridge Construction Using Modular Precast Elements requires a shift in mindset. Instead of managing on-site trades, the focus moves to factory schedules and transportation logistics, demanding close collaboration from all stakeholders from day one.

Logistical and Design Constraints

Transportation logistics are a primary challenge in modular construction and influence the entire project plan.

- Transportation: Moving large modules requires careful route planning to account for bridge clearances, sharp turns, and overhead lines. Manufacturing plants are typically located within 500 miles of the job site to keep transport costs manageable.

- Size Limitations: The size of a module is constrained by what roads and bridges can accommodate. Designers must work within these parameters from the start.

- Early Design Freeze: Unlike traditional construction, designs must be finalized before factory production begins. Changes become costly and time-consuming once manufacturing is underway. This requires more upfront investment in the design phase, often using Design for Manufacturing and Assembly (DfMA) principles.

- Site Access: The final assembly site must have adequate space and access for large cranes to lift and position modules.

Regulatory, Financial, and Industry Adaptation

Modular construction also faces systemic challenges rooted in traditional industry practices.

- Regulatory Problems: Building codes and permitting processes can vary significantly between jurisdictions. While the International Building Code (IBC) provides a foundation, a lack of standardized approvals for factory-built components can create complexity. Progress is being made toward state-level or third-party certification, but it’s not yet universal.

- Financial Models: Traditional construction loans are often tied to on-site progress. Modular projects require significant upfront capital for factory production, creating a mismatch with conventional financing. Specialized lending models are emerging but are not yet standard.

- Industry Mindset: The greatest challenge is shifting ingrained practices. Architects, contractors, and developers must learn to collaborate in new ways, embracing integrated supply chains and factory-to-site logistics. This transition also requires training and upskilling for the labor force.

At FDE Hydro™, we steer these challenges by working closely with regulatory bodies and educating stakeholders, proving through real-world projects that these methods deliver on their promises.

The Future is Modular: Technology and Market Trends

The journey of modular construction techniques from niche solution to mainstream method is being propelled by rapid technological advancements. We are witnessing a fundamental change in how buildings are conceived, produced, and assembled, making modular not only more efficient but also capable of greater design complexity and quality.

Digital tools and manufacturing principles are converging to pave the way for widespread adoption across sectors, open uping new possibilities for the built environment.

Technologies Driving the Modular Revolution

Several breakthrough technologies are leading the charge in modern modular construction:

- Building Information Modeling (BIM): This 3D modeling system integrates all architectural, structural, and MEP details into a single coordinated model, allowing designers to identify clashes and optimize for manufacturing before production begins.

- Design for Manufacturing and Assembly (DfMA): This approach guides designers to create components that are easy to manufacture in a factory and simple to assemble on-site, maximizing efficiency and quality.

- Automation and Robotics: Robotic arms perform repetitive tasks like welding, cutting, and material handling with speed and precision, improving safety and consistency.

- Digital Twins: These virtual replicas of physical assets track modules through their entire lifecycle, enabling predictive maintenance and smarter logistics. The Global Infrastructure Hub’s Infratech Use Case library showcases how these tools are reshaping infrastructure.

- IoT and Supply Chain Technology: Embedded sensors track location and condition during transit, ensuring quality control across the supply chain.

- 3D Printing: While still emerging for large structural elements, this technology is increasingly used for complex non-structural components and custom molds, offering greater design freedom.

Future Trends in Modular Construction Techniques

The future of modular construction techniques is dynamic, with several exciting trends shaping the industry:

- Greater Customization: Early modular was often seen as uniform, but digital design and flexible manufacturing now allow for unique, aesthetically striking buildings that still benefit from factory efficiency.

- High-Rise Modular Buildings: The precision and strength of factory-built modules are ideal for vertical construction, and modular towers are rising higher each year, proving the method’s scalability.

- Smart Building Integration: Modules can arrive on-site pre-equipped with smart home systems and energy management solutions, ensuring higher quality and better performance from day one.

- Disaster Relief and Emergency Housing: The ability to rapidly deploy safe, functional housing and infrastructure is critical in a crisis. Modular units can be stockpiled and deployed within days.

Applications for modular construction techniques continue to expand into specialized sectors. At FDE Hydro™, our Modular Powerhouses demonstrate how these methods can handle complex energy infrastructure. Other growing applications include data centers, healthcare facilities, affordable housing, hotels, schools, and retail spaces.

By 2030, the market for modular construction could reach $130 billion in Europe and the United States. This reflects growing confidence that modular methods are central to addressing global challenges like housing shortages and climate change.

Frequently Asked Questions about Modular Construction

How much faster is modular construction than traditional building?

Yes, modular construction techniques are significantly faster. Projects typically finish 20% to 50% faster than traditional methods. The speed advantage comes from parallel processing: modules are fabricated in a factory at the same time site preparation and foundation work are being done. This eliminates sequential dependencies and weather delays, allowing for assembly in days or weeks instead of months.

Is modular construction cheaper?

While upfront material costs can be similar, modular construction techniques can deliver up to 20% in total project cost savings. The savings are realized through several factors:

- Reduced Labor Costs: Factory efficiency is higher than on-site labor.

- Less Waste: Factory precision reduces material waste by up to 90%.

- Faster Completion: A shorter construction timeline reduces financing costs and allows for a quicker return on investment.

Across the US and Europe, modular methods could generate annual savings of up to $22 billion. Our experience at FDE Hydro™ also shows Why Precast Cost Less for large-scale infrastructure.

Are modular buildings as strong and durable as traditional ones?

Yes, permanent modular buildings are just as strong and durable as traditionally built structures—and often stronger.

Every modular building must meet the same local, state, and national regulations as its site-built counterpart, including the International Building Code (IBC).

Furthermore, modules are engineered with extra structural integrity to withstand the stresses of transportation and craning. The factory environment also ensures higher quality control, as materials are protected from weather and every component is built to precise standards under rigorous inspection. The result is construction quality that often surpasses what is achievable on an exposed job site.

Conclusion: Building a Smarter, More Sustainable Future

We have reached a pivotal moment in construction. Modular construction techniques address the industry’s most persistent challenges: chronic delays, spiraling costs, safety risks, and environmental harm.

The evidence is compelling. Projects completed 20-50% faster, with cost savings up to 20%. Material waste slashed by 83%, and on-site accidents reduced by over 80%. These are not just statistics; they are solutions.

By shifting construction into controlled factory environments, we are fundamentally improving how we build. This approach delivers superior quality, safer working conditions, and a dramatically lower environmental impact. Given that construction generates nearly 40% of global carbon emissions, the sustainability advantages of modular are essential.

Challenges in logistics, regulation, and finance remain, but technology is accelerating our ability to overcome them. BIM, robotics, and digital twins are making modular construction more precise and efficient than ever, as noted in McKinsey’s analysis on construction’s digital future.

At FDE Hydro™, we have seen this change in the demanding hydropower sector. Our patented “French Dam” system proves that modular precast technology can deliver critical infrastructure faster, more affordably, and with less disruption. We are committed to Aging Infrastructure Being Replaced with Next Generation Civil Solutions.

The construction industry can continue with century-old methods or accept a smarter approach. Modular construction techniques are the strategic path forward for any organization serious about efficiency, sustainability, and quality.

The future of construction is here. It’s modular, it’s digital, and it’s ready to transform how we build our world.

Learn more about our innovative modular dam solutions