Why Non-Powered Dams Are the Next Frontier in Clean Energy

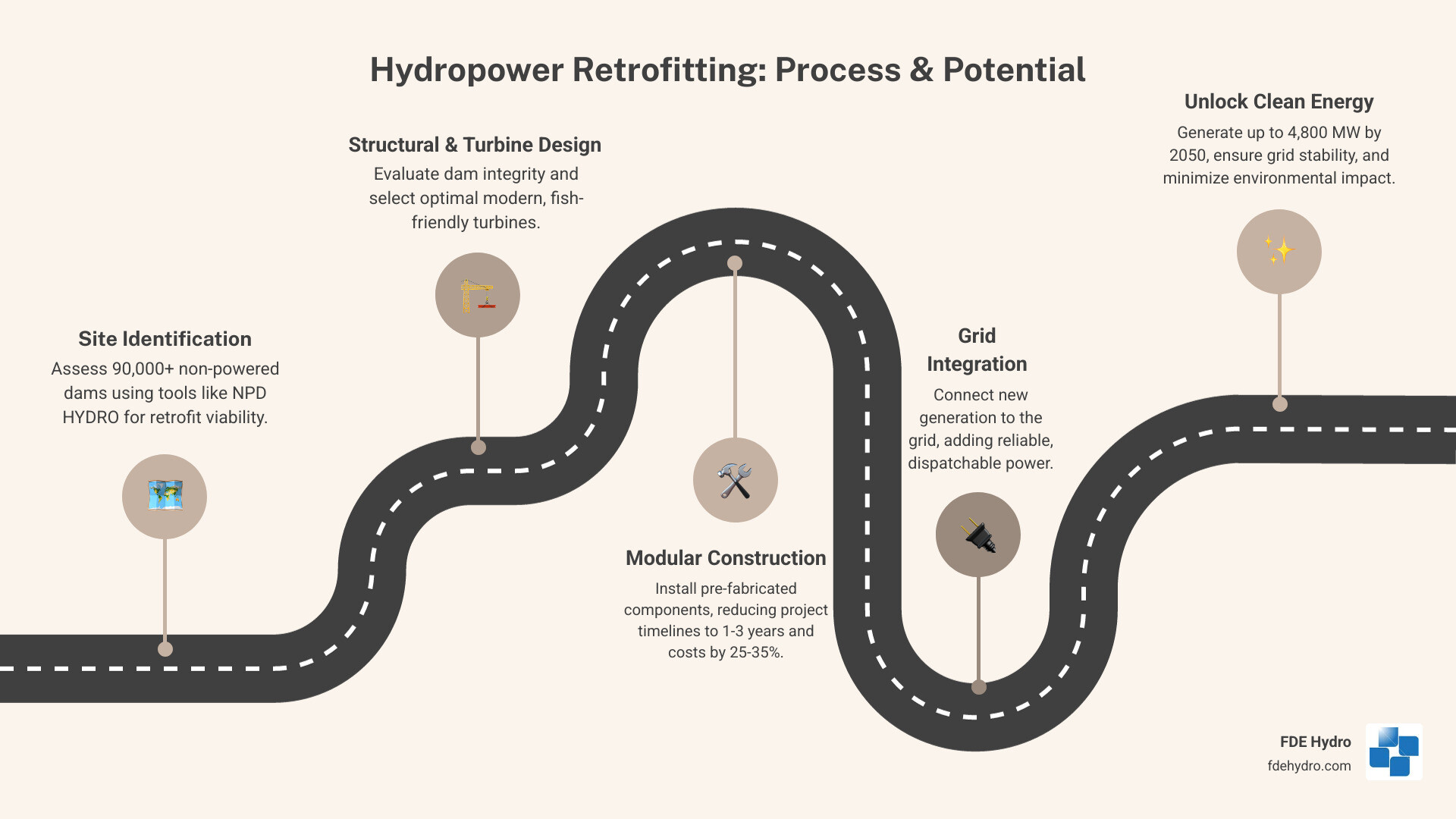

Hydropower retrofitting is the process of adding electricity generation to existing non-powered dams or upgrading aging hydropower facilities. This approach leverages existing structures to generate clean energy, avoiding the high environmental and financial costs of building new dams. Key benefits include minimal ecosystem disruption, 25-35% lower capital costs, and the addition of reliable power to stabilize a grid increasingly reliant on intermittent solar and wind.

Consider the Red Rock Dam in Iowa. For 50 years, it served only for flood control. After a recent retrofit, it now generates enough electricity to power 18,000 homes annually—without building a single new structure.

This is the promise of hydropower retrofitting: changing dormant infrastructure into clean energy assets. Across the United States, more than 90,000 dams exist, but less than 3% generate power. Retrofitting these structures could add 4,800 megawatts of economically feasible capacity by 2050, helping the nation meet ambitious renewable energy targets. As of January, 88 such projects were in the Federal Energy Regulatory Commission’s (FERC) development pipeline.

However, challenges like aging infrastructure, lengthy regulatory processes, and difficult financing must be addressed. Innovation is key to overcoming these problems. New assessment tools, modern turbine designs, and modular construction are making projects faster and more cost-effective.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, where we’ve pioneered modular civil construction solutions for hydropower retrofitting. After five decades in heavy civil construction and participation in the Department of Energy’s Hydropower Vision Technology Task Force, I’ve seen how innovation can dramatically reduce project timelines and costs while expanding clean energy capacity.

The Untapped Potential: Why Retrofit Non-Powered Dams?

Of the 90,000+ dams in the United States, fewer than 3% generate electricity. The rest manage floods, store water, or support irrigation, but produce zero power. These non-powered dams (NPDs) represent a massive, overlooked opportunity in our clean energy transition. As LeRoy Coleman of the National Hydropower Association notes, the industry’s focus has shifted to “develop on what’s out there.” This is the core of hydropower retrofitting: working smarter with existing assets.

This approach allows us to meet clean energy goals, strengthen grid reliability, and create economic benefits with minimal environmental impact. It’s not about building more dams; it’s about making existing ones work harder.

Meeting Clean Energy Demands

As pressure to decarbonize intensifies, hydropower retrofitting is a game-changer. The DOE Hydropower Vision report estimates that retrofitting could add up to 12,000 megawatts (MW) of capacity to the U.S. grid, with 4,800 MW being economically feasible by 2050. That’s enough to power millions of homes without building a single new dam. The potential is global, with modernization in Europe projected to boost generation by over 8%.

Retrofitting is attractive because it leverages existing infrastructure. The dam, reservoir, and often transmission lines are already in place. Even environmental groups, typically skeptical of hydropower, often see retrofits as a pragmatic solution because they work within an existing footprint, avoiding the impacts of new construction. This aligns with sustainable development by maximizing past investments and contributing to carbon reduction goals.

For more on how hydropower fits into our clean energy future, the U.S. Department of Energy hydropower resources offer detailed information.

Enhancing Grid Stability and Reliability

Solar and wind power are vital but intermittent. Hydropower provides the dispatchable, on-demand power needed to ensure a stable grid 24/7. It is the perfect partner for integrating renewables, ramping up when solar drops off and down when wind surges.

The most powerful example is pumped storage hydropower (PSH)—essentially a giant water battery. When electricity is cheap and abundant, water is pumped to an upper reservoir. When demand spikes, the water is released through turbines to generate power. PSH accounts for over 94% of the world’s long-duration energy storage capacity, providing critical services like frequency control and black-start capability.

The Bath County PSH example in Virginia can power 750,000 homes and has been a stabilizing force on the grid for decades. Even smaller, conventional retrofits contribute by adjusting their output in real-time to balance the grid—a flexibility that becomes more valuable as we add intermittent renewables.

Economic and Community Benefits

Retrofitting an existing dam is far more economical than building a new one. Research shows that converting existing plants to pumped storage can cost 25-35% less than new installations. These savings are attracting significant private investment and are further encouraged by federal funding in the bipartisan infrastructure package and state-level incentives like those in Colorado.

Retrofitting delivers a “trifecta” of benefits: new clean energy, construction and operations jobs, and the modernization of aging infrastructure. The NPD HYDRO tool, developed to prioritize retrofit opportunities, considers community and industry factors to ensure projects align with local needs. Modern automation and digitalization are also making smaller projects economically viable for municipalities and local utilities, fostering energy independence and keeping energy dollars in the community.

The return on investment for hydropower retrofitting is measured not just in kilowatt-hours, but in jobs, improved infrastructure, and a more stable, sustainable grid.

Navigating the Challenges of Hydropower Retrofitting

While the potential of hydropower retrofitting is enormous, the path is not without obstacles. From aging concrete to complex regulations, these challenges are significant but solvable. Every existing dam is both an opportunity and a puzzle to be solved with careful engineering and planning.

Overcoming Technical and Structural Problems

Many hydropower plants are over 40 years old, meaning we are working with infrastructure that predates modern engineering standards. Dam structural integrity is the first concern. At FDE Hydro™, our modular precast concrete technology addresses this directly. Our dam rehabilitation encapsulation approach strengthens existing structures while adding power generation capabilities, extending their lifespan and usefulness.

Water availability is another challenge, as climate change creates less predictable flows. California, for example, faces projections of reduced hydropower output due to droughts. This requires flexible turbine designs that operate efficiently across a wide range of conditions. Sediment management is also critical, as decades of buildup can impact a dam’s structure and turbine efficiency. Modern technologies like 3D modeling and advanced, adaptable turbines help tackle these site-specific engineering problems before construction begins.

Clearing Policy and Financial Roadblocks

Regulatory and financial barriers can be as challenging as technical ones. The FERC licensing process in the U.S. is notoriously lengthy, sometimes taking over a decade. As of January, 88 retrofit projects were waiting in the FERC hydropower development pipeline, representing a significant amount of stalled clean energy potential.

High upfront capital costs and declining power purchase agreement (PPA) rates make financing difficult. For pumped storage projects, the market often fails to properly value their critical grid-stabilizing services. We need supportive policies that recognize the full value of hydropower’s flexibility and storage.

Fortunately, help is on the way. The 21st Century Dams Act and the $1.2 trillion bipartisan infrastructure package aim to expand funding and incentives for retrofitting. Other proposed solutions include extending tax credits and streamlining the permitting process. States like Colorado are also creating models for de-risking projects through low-cost financing. The path forward requires both patience and advocacy to open up the full potential of hydropower.

Innovative Approaches and Modern Technologies

The landscape of hydropower retrofitting is being reshaped by innovation. We are seeing fundamental changes in how we identify, design, and build projects, making them faster, cheaper, and more environmentally sound.

A Spectrum of Hydropower Retrofitting Approaches

No two dams are alike, so hydropower retrofitting requires a spectrum of solutions. For non-powered dams, simple turbine addition is the most direct path, with modern, submerged designs minimizing construction. For existing power-generating dams, upgrading turbines can boost output by up to 20%, while refurbishing civil works can yield increases of 50% or more.

Pumped storage conversion is an exciting frontier, turning existing plants into long-duration energy storage assets. The boosterpump concept makes this more affordable, costing 25-35% less than installing new reversible units. Other operational improvements, like optimizing reservoir levels and modernizing waterways, can also yield significant gains. Our FDE Hydro™ modular precast concrete technology, the “French Dam,” was designed to streamline these approaches. By drastically reducing construction costs and timelines, we make more retrofitting projects economically viable.

The Role of New Tools in Hydropower Retrofitting

Sophisticated digital tools are replacing the guesswork of the past. The NPD HYDRO tool, developed by national laboratories and consultants, analyzes hundreds of non-powered dams across grid, community, industry, and environmental factors. This helps decision-makers focus on the most promising projects.

Digitalization is also revolutionizing plant operations. While hydropower has lagged, it’s catching up fast. IoT platforms enable remote monitoring and control, while AI-powered predictive maintenance helps avoid costly failures. These digital advances can improve overall efficiency and increase annual generation by up to 11% by optimizing water use. Before construction, advanced simulation and modeling provide certainty, using 3D models and fluid dynamics to verify designs and give investors confidence.

Balancing Power with Environmental Protection

If hydropower retrofitting isn’t environmentally responsible, it isn’t sustainable. Fortunately, innovation is making it possible to generate clean energy while protecting aquatic ecosystems. Fish-friendly turbines are a major advance, engineered to allow safe passage and reduce the need for costly exclusion screens.

Environmental flow management—maintaining sufficient downstream water flow to support river health—is now standard practice. Water quality monitoring has also advanced, with technologies like environmental DNA (eDNA) allowing for precise biodiversity tracking. This data enables adaptive management, where operations can be adjusted based on real-time ecological conditions. For projects seeking to prove their credentials, the Low Impact Hydro Institute certification provides rigorous third-party verification.

Research shows that when modernization doesn’t worsen the physical characteristics of rivers, it creates little conflict with environmental objectives. The goal is to generate more power from existing infrastructure without increasing environmental impact. This isn’t just good ethics; it’s good business.

Success Stories and the Future Outlook

The best way to understand the power of hydropower retrofitting is to look at real projects. These aren’t just possibilities—they’re working dams generating clean electricity, proving we can breathe new life into aging infrastructure.

Case Study: Powering a U.S. Dam

The Red Rock Dam in Iowa, once used only for flood control, now powers 18,000 homes after a retrofit. It’s not alone. Since 2000, 36 U.S. dams have been successfully retrofitted, adding over 500 megawatts of renewable capacity. These projects often succeed through public-private partnerships, which bring together the right expertise and financing. For example, long-term power purchase agreements for facilities at existing U.S. Army Corps of Engineers dams create stable revenue streams that make projects financially viable.

Private investment is also flowing into this sector, with hundreds of millions of dollars being licensed for retrofits at dozens of sites. These numbers show that hydropower retrofitting isn’t just environmentally sound; it makes economic sense. These success stories create replicable models that can be scaled up nationwide.

Modernization Efforts in North America and Beyond

The retrofitting revolution is global. Canada is actively pursuing “made-in-Canada solutions” to update its large hydropower fleet, while cross-border collaboration with the U.S. helps share knowledge and technology. In Europe, modernization is projected to increase energy generation by 8.4% for the European Union. The EU-funded ReHydro project, with partners from seven countries, exemplifies this spirit by demonstrating pumped-storage conversions and developing eel-friendly turbines.

Our work at FDE Hydro™ contributes to these efforts by bringing our modular precast concrete technology to projects. We’ve seen how innovative construction approaches can accelerate timelines and make modernization economically feasible.

The Future of Dam Retrofitting

Looking ahead, the trajectory for hydropower retrofitting is exciting. The U.S. Department of Energy projects potential for more than 30 gigawatts of pumped storage hydropower capacity—the “water batteries” critical for a renewable-heavy grid. Globally, 600 GW of pumped storage projects are in development, signaling strong momentum.

Continued innovation will drive this growth. Fish-friendly turbines, AI-powered control systems, and modular construction techniques—like our FDE Hydro™ precast technology—are slashing project timelines and costs. While modernization requires upfront capital, the benefits are clear: decades of reliable clean energy and critical grid services. With a 50-to-100-year asset life, the return on investment for hydropower is very attractive. Events like the World Hydropower Congress reinforce the consensus that retrofitting existing infrastructure plays a strategic role in the energy transition.

Conclusion

Hydropower retrofitting is not just a smart idea—it’s an essential component of our clean energy future. By adding power to non-powered dams and upgrading existing facilities, we can meet ambitious energy targets, strengthen grid stability, and create economic opportunities, all while using infrastructure that is already in place.

While challenges like aging structures, lengthy regulations, and complex financing are real, innovation is providing the solutions. Success stories from Iowa’s Red Rock Dam to Europe’s ambitious modernization programs prove that retrofitting works. New tools, fish-friendly turbines, and advanced digital controls are making projects more efficient and environmentally sound.

At FDE Hydro™, we are at the forefront of this change. Our patented modular precast concrete technology—the “French Dam”—fundamentally alters the economics and timelines of retrofitting. We can reduce construction time from a decade to as little as one to three years, with cost reductions of 25-35% compared to conventional methods. This makes a critical difference when every year of delay is a missed opportunity for clean energy.

Those 90,000+ non-powered dams in the U.S. represent thousands of megawatts of untapped potential. The path forward requires partnership between innovative companies, supportive policymakers, and forward-thinking communities. We are committed to being your partner in this transition, bringing five decades of experience and cutting-edge modular technology to your project.

The future of hydropower is about working smarter with what we have. It’s about turning dormant concrete into productive clean energy assets. Let’s build that future together.

Learn more about our innovative hydropower solutions