Why Hydropower Innovation Case Studies Matter More Than Ever

Hydropower innovation case studies reveal how the renewable energy sector is changing to meet dual demands: generating more clean electricity while protecting river ecosystems. Here’s what you need to know:

Key Innovation Areas:

- Modernization of aging plants – Nearly 40% of global hydropower facilities are over 40 years old and need upgrades

- Fish-friendly turbines – New designs achieve 98%+ survival rates while maintaining efficiency

- Retrofitting existing infrastructure – Reusing dams, canals, and weirs cuts costs by 20-30%

- Digital twins and AI – Real-time monitoring improves efficiency by 1.2% and prevents failures

- Community-centered development – Projects like Tina River create 440+ local jobs while reducing CO2 by 49,500 tonnes annually

The global hydropower fleet faces a critical moment. With investment declining to $50 billion in 2023 (down from previous years) and generation decreasing by over 100 TWh, the industry must innovate or risk falling behind solar and wind. Yet hydropower remains essential—it provides more than 90% of global energy storage capacity and offers best grid stability.

The challenge isn’t just technical. Hydropower projects must balance decarbonization goals with ecosystem protection, satisfy local communities, and deliver returns despite long development timelines. Traditional construction methods—slow, expensive, and environmentally disruptive—no longer meet these demands.

That’s where innovation makes the difference. From modular construction that cuts installation time from 9 years to 6 to turbines that let fish pass safely through, these case studies show practical solutions that work today.

I’m Bill French Sr., Founder and CEO of FDE Hydro, where I’ve spent years developing modular precast concrete solutions that reduce both construction time and environmental impact for hydropower projects. Through analyzing hydropower innovation case studies from Europe to the Pacific Islands, I’ve seen how the right technologies can transform project economics while protecting the rivers we depend on.

Terms related to hydropower innovation case studies:

The Dual Challenge: Modernizing an Aging Fleet While Protecting Ecosystems

Hydropower faces a dual challenge: modernizing its aging infrastructure to meet growing clean energy demands while protecting the river ecosystems it impacts.

The aging infrastructure problem is significant. Nearly 40% of the global hydropower fleet (476 GW) is over 40 years old, with many plants in North America and Europe now facing reduced efficiency, higher maintenance, and outdated environmental protections. Modernization is essential for reliable, sustainable energy.

This challenge is compounded by declining investment, which fell to around USD 50 billion in 2023. This is concerning given hydropower’s unique role in providing grid stability and flexibility. Pumped storage alone offers over 90% of the energy storage in the EU, balancing intermittent renewables like solar and wind. Without investment in modernization, this vital grid stability is at risk.

Environmentally, traditional hydropower can alter river flows, harm aquatic life, and block fish migration. Climate change exacerbates these issues with erratic rainfall affecting water availability and production. However, these challenges are driving innovation.

For example, digitalization can improve efficiency by 1.2%, potentially adding 42 TWh to global production annually. Retrofitting existing non-powered dams and upgrading facilities offers even greater promise, cutting costs by up to 277 €/kW and reducing investment periods from nine years to six by reusing existing infrastructure.

Modernization gains are substantial, with potential generation increases of 8.4% in Europe and 8.8% in the U.S. from upgrades alone. These retrofits also improve a plant’s flexibility to support grids with high solar and wind penetration. Furthermore, upgrading facilities improves their multipurpose benefits, such as irrigation, flood management, and potable water supply. Addressing these challenges requires new technologies, construction practices, and policies to secure hydropower’s role in a clean energy future.

Pioneering Hydropower Innovation Case Studies

The future of clean energy isn’t just about building new—it’s about building better. Around the world, we’re seeing hydropower innovation case studies that prove we can meet our climate goals while protecting the rivers and ecosystems we depend on. These projects show what’s possible when innovation meets determination.

Case Study: The Tina River Project – A Model for Sustainable Development

The Tina River Hydropower Project in the Solomon Islands is a global blueprint for sustainable development. Previously reliant on expensive imported diesel, the nation’s capital now receives 68% of its electricity from this clean energy source. The project reduced diesel dependence from 97% to 30% and cuts CO2 emissions by 49,500 tonnes annually.

What makes the project a standout case study is its focus on community. It created 440 local jobs and established a landowner royalty scheme benefiting over 4,000 people, turning them into partners in success. Financially, it was the nation’s first large-scale public-private partnership, securing a USD 240 million package from a consortium including the World Bank and Green Climate Fund. This model, using concessional financing and risk insurance, demonstrates how to de-risk projects in challenging markets and aligns with The Solomon Islands’ development strategy.

Greening the Flow: Ecologically-Improved Turbines and Operations

For decades, hydropower dams that generated clean electricity could harm river ecosystems. That’s changing fast.

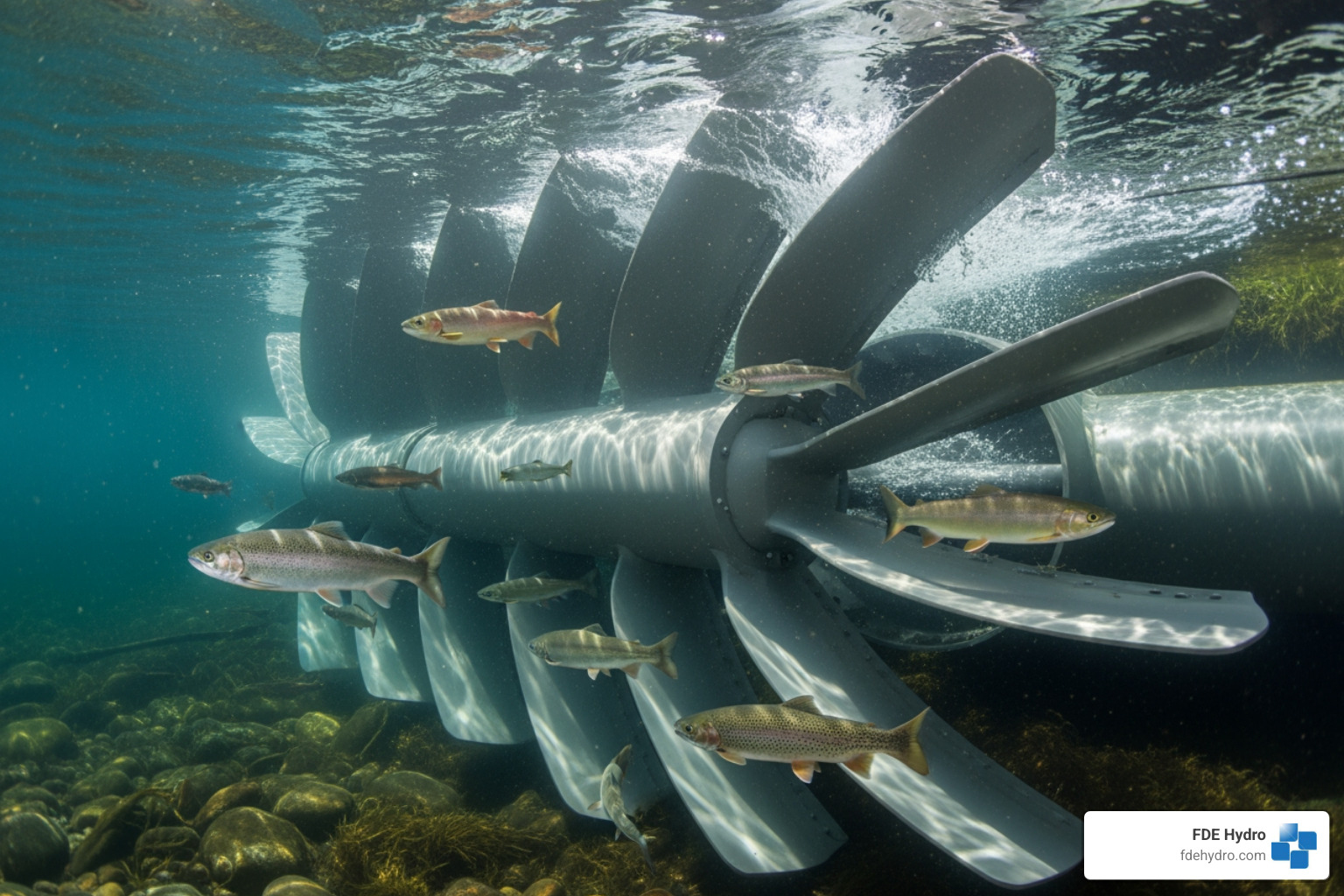

The development of ecologically improved turbines is a major advance. At the Ice Harbor Lock and Dam in Washington State, modifications achieved over 98% fish survival rates. Technologies like the Minimum Gap Runner, Alden turbine, and DIVE turbine are engineered to minimize blade strikes and pressure injuries. Other innovations include water-lubricated bearings, which eliminate the risk of oil contamination.

Another critical innovation addresses hydropeaking—rapid water flow fluctuations. In Bolzano, Italy, a plant installed demodulation reservoirs to release water gradually, dramatically improving river conditions. Smarter management of environmental flows and the use of low head hydropower converters are also opening up new, previously unusable sites like weirs and irrigation canals, often at a lower cost (less than 5,000 €/kW).

Open uping Hidden Potential: Hydropower Innovation Case Studies in Existing Infrastructure

What if the best hydropower opportunities lie not in new dams, but in using what we already have? Tens of thousands of non-powered dams, weirs, and canals exist across North America and Europe. Retrofitting these for power generation is an enormous, economically smart, and environmentally responsible opportunity.

The advantages are substantial. Reusing existing infrastructure can save approximately 277 €/kW, and the investment period can shrink from nine years to six. The environmental footprint is minimal, with no new river fragmentation. Permitting is also typically faster.

The potential is vast: in the U.S., an analysis of 54,000 non-powered dams has already led to dozens of projects. Modernizing existing hydropower plants is another key opportunity, with the potential to boost generation by 8.4% in Europe and 8.8% in the U.S. This is where modular precast concrete technology, like the systems developed at FDE Hydro, makes a significant impact. Our approach minimizes on-site construction, making it ideal for open uping the hidden potential in existing infrastructure across North America, Brazil, and Europe.

The Digital Wave: Changing Hydropower with Technology

If you’ve ever wondered what the future of hydropower looks like, it’s happening right now—and it’s digital. We’re living through a remarkable change where hydropower innovation case studies increasingly showcase smart grids, advanced data analytics, and artificial intelligence working alongside traditional turbines and generators. This isn’t science fiction; it’s the practical reality reshaping how we generate clean, reliable electricity.

This digital revolution is critical for keeping hydropower competitive. Smart grids allow plants to respond dynamically to electricity demands, while predictive maintenance uses AI to anticipate equipment failures, scheduling repairs before they cause outages. Organizations like the IEA Hydropower Technology Collaboration Programme help accelerate the adoption of these technologies by sharing innovations globally.

How Digitalization is Changing Hydropower Operations and Maintenance

Digitalization can improve overall efficiency by 1.2%. While that may not sound earth-shattering, for large-scale facilities it translates into significant additional clean energy. An Italian plant, for example, used data-driven software to increase annual production by exactly 1.2%.

Real-time monitoring systems are now the eyes and ears of modern plants, giving operators immediate insights that prevent problems. The most fascinating development is the “digital twin”—a virtual model of a physical plant that receives real-time sensor data. At the La Bâtiaz power plant in Switzerland, a digital twin has monitored penstock fatigue since 2014. It revealed that certain grid services could increase fatigue wear tenfold, allowing operators to adjust strategies to balance grid support with equipment longevity. This fatigue monitoring is crucial for aging infrastructure.

The shift to predictive maintenance is another practical benefit, minimizing outages and reducing costs. At FDE Hydro, we see how this digital change complements our modular precast concrete technology. Combining rapid construction with smart operational systems creates facilities that are built faster and perform better from day one.

The Role of Policy and International Collaboration in Driving Innovation

Innovation requires supportive policies and international collaboration. Behind every successful hydropower innovation case study are frameworks that allow new ideas to grow. International financial institutions like the World Bank, the International Finance Corporation (IFC), and the Asian Development Bank (ADB) play a key role by de-risking ambitious projects, making them attractive to private investors.

National development strategies provide long-term vision, while regional agreements like Europe’s “Guiding Principles on Sustainable Hydropower Development in the Danube Basin” harmonize standards for environmental protection. Organizations like the IEA Hydropower Technology Collaboration Programme are vital for accelerating progress by sharing knowledge across borders. Key policy recommendations include streamlining regulations, creating market mechanisms that fairly compensate hydropower for its grid services, and supporting modernization. These efforts create the environment where technological innovations can thrive.

Frequently Asked Questions about Hydropower Innovation

How does innovation make hydropower more environmentally friendly?

Modern innovation is fundamentally changing hydropower’s relationship with river ecosystems. Key improvements include:

- New Turbine Designs: Technologies like the Minimum Gap Runner and Alden turbine are designed to be ‘fish-friendly,’ achieving over 98% fish survival rates at some sites by minimizing blade strikes and pressure changes.

- Oil-Free Systems: Water-lubricated bearings and other oil-free components eliminate the risk of petroleum leaks, protecting water quality.

- Advanced Operations: To mitigate hydropeaking (rapid flow changes that harm habitats), plants like the S. Antonio facility in Italy use demodulation reservoirs to release water gradually, restoring more natural river conditions.

- Better Sediment Management: New approaches, including continuous de-sedimentation systems, help restore the natural transport of sediment, which is vital for downstream ecosystems.

Can we add hydropower to dams that don’t currently produce power?

Yes, and this is one of the most exciting opportunities in renewable energy right now! Thousands of non-powered dams (NPDs) exist in the U.S. and Europe, built for flood control or irrigation. Adding power generation to these structures, a practice known as retrofitting, leverages existing infrastructure and avoids the environmental impact of building new dams.

The economics are compelling. Reusing existing pipes and reservoirs can save approximately 277 €/kW, and installing low head converters can cost less than 5000 €/kW, making previously uneconomical sites viable. Studies have identified significant potential, with dozens of projects already operational or in development in the US and Europe. Modular technologies, like FDE Hydro’s precast concrete solutions, are ideal for these retrofits, accelerating timelines and making projects more cost-effective.

What is a “digital twin” in hydropower?

A digital twin is a virtual, real-time replica of a physical hydropower plant. It receives a constant stream of data from sensors on the actual equipment, monitoring everything from pressure and vibration to structural stress. Its primary uses are:

- Predictive Maintenance: By analyzing data patterns, the digital twin can predict potential equipment failures before they happen. This allows maintenance to be scheduled proactively, avoiding costly outages and extending equipment life.

- Performance Optimization: The twin can run simulations to identify inefficiencies, helping to optimize operations and increase energy output, often by more than 1%.

- Structural Health Monitoring: For aging components like penstocks, a digital twin provides continuous fatigue monitoring. For example, the Hydro-Clone twin at Switzerland’s La Bâtiaz plant helped operators understand how different operations affected component wear, allowing them to adjust strategies to prolong the plant’s life.

A digital twin gives you unprecedented visibility into your plant’s health and performance. It’s like having an expert constantly watching, analyzing, and advising—helping you maximize reliability, efficiency, and longevity throughout your facility’s operational life.

Conclusion: Powering a Sustainable Future with Innovative Hydropower

We’ve journeyed through some remarkable hydropower innovation case studies together, and I hope you’ve seen what I’ve witnessed firsthand: this industry is at an exciting turning point. We’re not just maintaining the status quo—we’re reimagining what hydropower can be in the 21st century.

The path forward is becoming clearer. Sustainability isn’t a constraint; it’s an opportunity. Innovations from fish-friendly turbines to digital twins prove that protecting ecosystems and generating clean energy can be achieved together.

We’re sitting on hidden treasure. Across North America, Brazil, and Europe, thousands of existing structures—non-powered dams, irrigation canals, old weirs—are waiting to be transformed into clean energy sources. The cost savings are real: 277 €/kW by reusing irrigation infrastructure, installation costs under 5000 €/kW for low head converters. These represent practical, achievable projects that can move forward today without the environmental disruption of new construction.

Technology is reshaping everything we thought we knew about operations. Digitalization is adding 1.2% efficiency improvements that translate into millions of additional kilowatt-hours annually. For an aging fleet where 40% of plants are over 40 years old, this digital revolution couldn’t come at a better time.

None of this happens in isolation. The Tina River Project showed us how international collaboration, innovative financing, and community engagement can transform energy systems. The World Bank, IFC, and ADB aren’t just funding projects—they’re de-risking innovation and making sustainable development possible.

Here at FDE Hydro, we’re working every day to be part of this solution. Our modular precast concrete technology—what we call the “French Dam”—was born from recognizing these exact challenges. When construction timelines drop from nine years to six, when costs decrease by 20-30%, when environmental disruption is minimized—that’s when hydropower becomes accessible for more communities.

The future of hydropower is about intelligence, integration, and respect for the systems we work within. The innovations we’ve explored prove that belief is justified. We can power our modern world while protecting the natural world.

That’s the sustainable future these hydropower innovation case studies are building, project by project, innovation by innovation. And we’re proud to be part of it.

To learn more about how we’re changing hydropower development, visit our page on hydropower.