Why Hydropower Asset Management is Critical for Long-Term Success

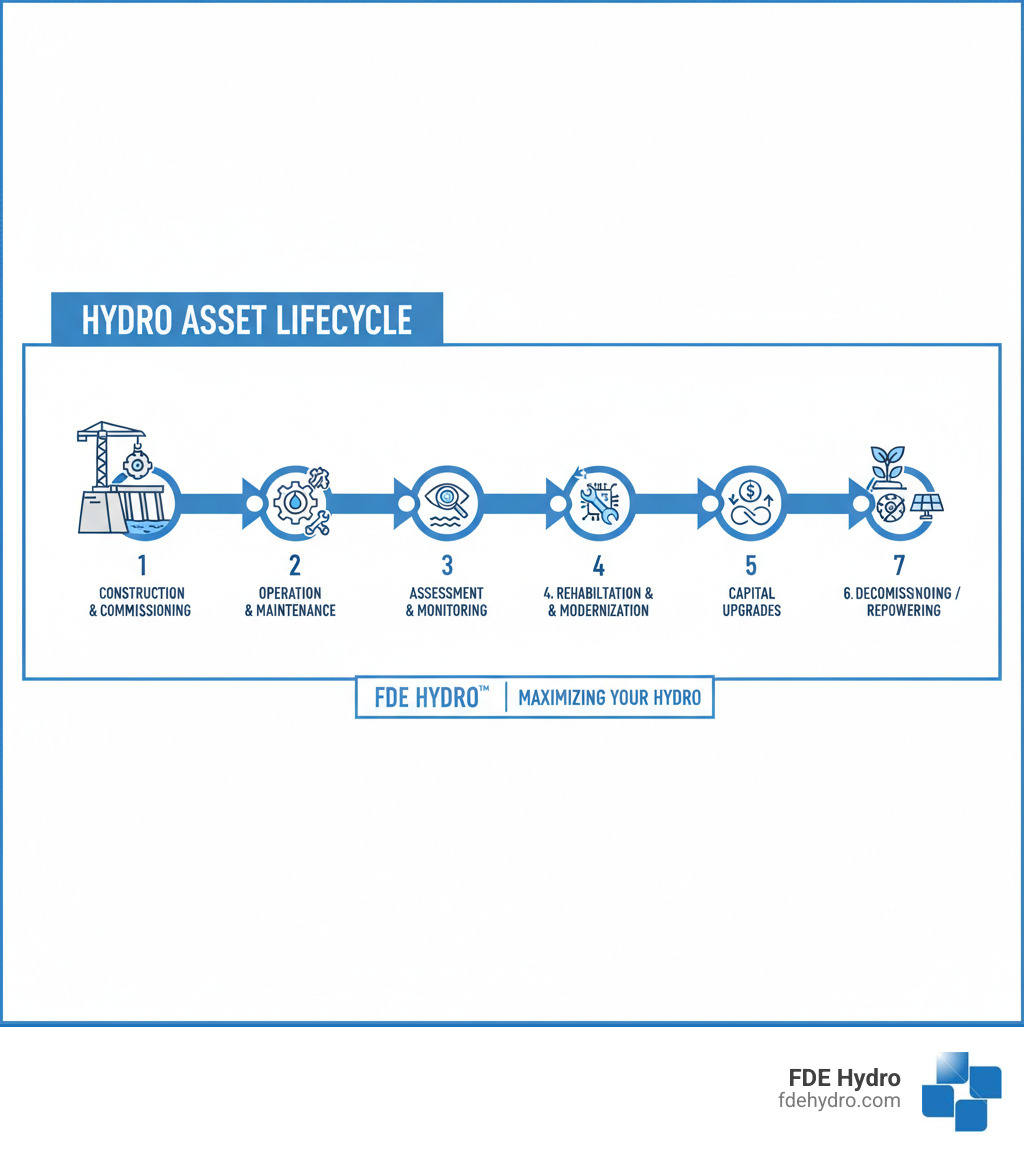

Hydropower asset management is a strategic approach to maintaining, operating, and optimizing hydroelectric facilities for maximum reliability, performance, and value over their lifecycle. Here’s what it involves:

Key Components of Hydropower Asset Management:

- Condition Assessment – Regular evaluation of equipment health using routine O&M data and specialized testing

- Risk-Based Prioritization – Ranking investments by likelihood and consequence of failure

- Data-Driven Decisions – Using CMMS/EAMS systems to track performance and predict maintenance needs

- Strategic Planning – Aligning maintenance budgets with long-term capital improvement goals

- Performance Optimization – Extending asset life while maximizing generation output and revenue

The stakes are high: most critical equipment in North American hydroelectric facilities is near or beyond its design life. For example, the average generator step-up transformer is over 34 years old. However, with robust asset management, hydropower facilities can operate for over 100 years—far longer than other generation technologies.

Many operators have data, but it’s often compartmentalized, incomplete, or low-quality, hindering good decisions. As equipment ages and regulations evolve, a lack of a comprehensive asset management approach leads to a reactive cycle of addressing failures instead of preventing them.

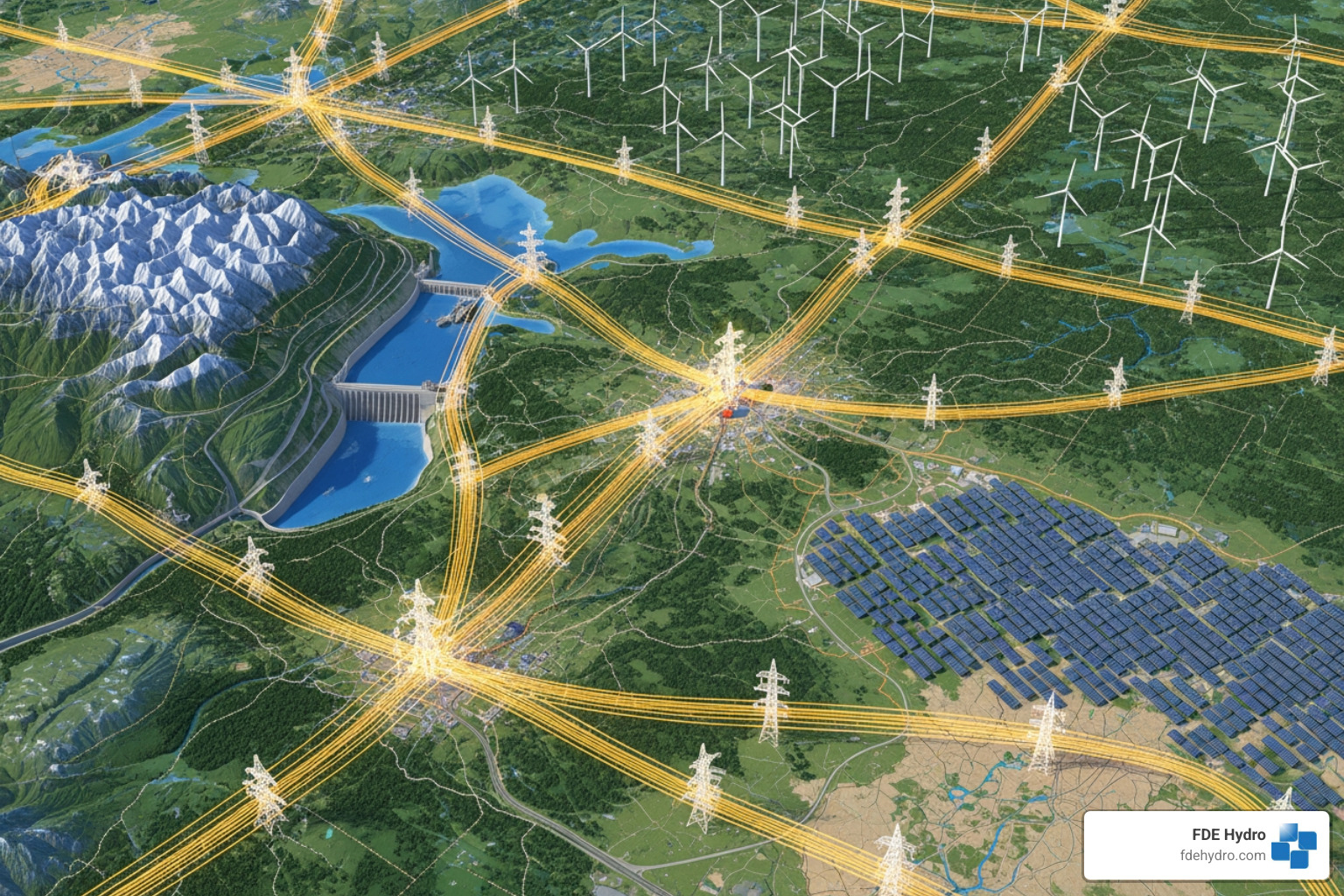

Hydropower’s role is more critical than ever in the energy transition. Its dispatchability and operational flexibility are essential for integrating intermittent renewables like wind and solar. To secure this role, operators must view asset management as a value creation tool, not just a cost center.

This requires moving from simple schedules to strategic programs using condition assessments, risk analysis, and economic modeling. It involves using frameworks like the Hydropower Asset Management Partnership (hydroAMP) and justifying improvements with data-driven insights on risk and opportunity, not just age.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, and I’ve spent decades in civil construction and hydropower innovation, including serving on the Department of Energy’s Hydro Power Vision Technology Task Force. Through this experience, I’ve seen how strategic hydropower asset management transforms facilities from aging liabilities into competitive, resilient assets that support the clean energy transition.

Hydropower asset management terms simplified:

The Core Components of a Resilient Hydropower Program

Aging infrastructure doesn’t mean declining performance. With strategic hydropower asset management, facilities can operate reliably and profitably for decades past their design life by moving from reactive to proactive management.

A resilient program builds organizational resilience—the ability to adapt to failures, market changes, or regulatory shifts. This requires integrating five key elements: program development, capital improvement planning, information solutions, operational performance monitoring, and condition assessment.

Program development establishes the framework for all asset-related decisions. The ISO 55000 series (ISO 55000, 55001, and 55002) offers a proven roadmap for building these systems, connecting leadership strategy with daily operations.

Capital Improvement Planning (CIP) turns the framework into action, optimizing the timing and sequence of investments to maximize value and manage risk.

Information solutions like a CMMS (Computerized Maintenance Management System) or EAMS (Enterprise Asset Management System) act as the program’s central nervous system, turning scattered data into actionable insights.

Operational performance tracking ensures assets deliver required reliability and output. Condition assessment provides the diagnostic data to determine when intervention is necessary or can be deferred.

When these components work together, they create a system that drives reliability and performance across the portfolio. More info about Hydropower Project Costs

Primary Objectives of Asset Management

Hydropower asset management is a means to achieve specific, measurable outcomes that impact your bottom line and operational success.

Operational excellence means facilities run smoothly and efficiently. It streamlines workflows, allowing teams to focus on optimizing performance and making maintenance strategic, not chaotic.

Minimizing downtime is a tangible benefit. A good program identifies potential failures early, allowing maintenance to be scheduled during low-value periods to avoid lost revenue and penalties from unplanned outages.

Risk reduction encompasses safety, environmental, and regulatory risks. Systematically addressing these risks protects personnel, profits, and compliance.

Cost-control is about finding the balance between under-maintaining (costly failures) and over-maintaining (wasted resources). The goal is the lowest lifecycle cost, not the lowest immediate expense.

Extending asset lifespan is critical for aging equipment. Strategic refurbishments and replacements can keep facilities productive for decades, with well-managed plants often operating for over 100 years.

Resource allocation ensures limited capital, personnel, and time are directed where they create the most value, with decisions based on data, not intuition.

Defining and Prioritizing Critical Assets

Not all assets deserve equal attention. Some failures are minor inconveniences; others can shut down an entire operation. Hydropower asset management is about knowing the difference and prioritizing accordingly.

This requires a system-level understanding of how components interact. A facility is an integrated system where one failure can cascade. For example, a small bearing failure could destroy a multi-million dollar turbine.

Criticality analysis combines failure likelihood with its consequences. A worn gasket is a low-consequence failure. In contrast, a generator step-up transformer failure can cause extended outages and catastrophic revenue loss, especially with procurement times of 18 months or more.

Failure probability assessment considers age, condition, maintenance history, and operating environment to help anticipate problems.

The consequence of failure evaluation considers lost revenue, repair costs, safety, environmental risks, and regulatory penalties, as well as spare part availability and lead times.

Combining these factors creates a risk profile for each asset, allowing you to rank assets and focus budgets on the components that matter most.

This isn’t about ignoring low-priority assets. It’s about ensuring that when your GSU transformer shows signs of degradation, you’re already planning for replacement rather than finding the problem during a catastrophic failure. More info about Hydroelectric Dam Components

Data-Driven Decisions: From Assessment to Action

The real challenge of hydropower asset management isn’t collecting data, but turning it into clear decisions and making it work for you.

Most facilities have decades of data in maintenance logs, reports, and records. The problem is that this data is often scattered, inconsistent, incomplete, and unreliable.

Modern information systems like Computerized Maintenance Management Systems (CMMS) and Enterprise Asset Management Systems (EAMS) are the backbone of data-driven hydropower asset management. They organize data, track equipment condition, and help spot patterns.

Software alone isn’t a solution. The real work is improving data quality through team training, clear procedures, and regular audits. It also requires developing analytical skills to recognize fleet-wide trends.

Getting this right allows you to see new cause-and-effect relationships, predict failures, justify investments with evidence, and automate routine decisions, freeing up your team for complex challenges.

The Role of Condition Assessments in Hydropower Asset Management

Condition assessments are the blueprints of hydropower asset management, revealing the real health of your equipment based on objective, measurable indicators, not just age or assumptions.

Tier 1 assessments provide a baseline using existing O&M data, age, and history. Assets are scored against standardized indicators to produce a Condition Index and a Data Quality Indicator. This streamlined approach avoids spending on specialized tests unless necessary.

Tier 2 evaluations are used when Tier 1 raises red flags or for critical equipment. They involve specialized, non-routine testing, often with outside experts. While more costly, this deeper analysis is essential for critical assets like a generator step-up transformer with a long lead time.

The Hydropower Asset Management Partnership (hydroAMP) is an invaluable industry resource. Its framework helps operators objectively evaluate equipment condition with standardized methods, supporting long-term investment strategies, annual budgets, and performance tracking. It helps facilities shift from reactive to strategic planning.

Learn about the hydroAMP framework

Analytical Tools for Investment Prioritization

Good condition data is only half the battle; it must be used to make smart investment decisions about which projects to fund, defer, and prioritize for the best ROI.

In hydropower asset management, we use two main analysis types: Type 1 for straightforward financial analysis and Type 2 for comprehensive risk-based evaluation.

| Analysis Type | Focus | Key Factors Considered | Application |

|---|---|---|---|

| Type 1 | Condition and Cost | Total cost, current-year cost, incremental maintenance, achievability, project phase, Condition Index. | Best for simpler investment decisions, such as replacing a relatively inexpensive piece of equipment like a compressor, where the primary concerns are the asset’s condition and the direct cost of repair or replacement. |

| Type 2 | Condition, Cost, and Consequence (Risk) | All Type 1 factors PLUS marginal value of generation, outage duration, revenue at risk, risk map score, other business factors (e.g., safety, legal, environmental, regulatory). | Essential for complex investment decisions involving critical power train equipment (generators, transformers, turbines), where the consequences of failure are significant and can impact multiple areas beyond direct cost, including lost revenue and grid reliability. |

Risk maps are a powerful tool, plotting equipment condition against consequence of failure. This visual instantly highlights top-priority vulnerabilities, like a generator in poor condition with high failure consequences.

For financial analysis, Net Present Value (NPV) is ideal. Unlike other metrics, NPV accurately accounts for the time value of money and all cash flows over a project’s lifespan, which is crucial for major, long-term investments.

For example, evaluating a generator and turbine replacement requires considering upfront cost, increased capacity, generation benefits, reduced maintenance, and avoided environmental costs, all projected over decades and discounted to today’s dollars using NPV. This rigorous, data-driven analysis provides solid justification for multi-million-dollar projects.

More info about Dam Rehabilitation

Strategic Hydropower Asset Management in a Modern Energy Market

As the energy world changes, hydropower asset management must keep pace. Hydropower is more essential than ever because, unlike solar and wind, it can deliver power on demand.

Hydropower facilities can ramp up or down quickly to meet demand. This dispatchability makes them perfect partners for intermittent renewables and guardians of grid stability, balancing the grid when other sources are unavailable.

This increased importance brings challenges and opportunities. Volatile energy markets require agile hydropower asset management strategies that optimize both equipment performance and market value creation.

Justifying Budgets for Capital Improvements

Securing budgets is a tough part of hydropower asset management. For example, the DOE recently requested $7 billion for hydropower improvements but received only $550 million, highlighting the need to make every dollar count.

A solid hydropower asset management program is your best advocate. With comprehensive data and analytical tools (like Type 1 and 2 analyses), you can build compelling business cases that show an asset’s risk profile, cost of failure, and ROI, going beyond simply stating its age.

This data-driven approach transforms capital planning from reactive to strategic. You can demonstrate that proactive replacement of a critical component, based on its condition and risk, saves more than waiting for a catastrophic failure and its associated costs.

Long lead times for major equipment (e.g., 18+ months for transformers) are another crucial factor. Good asset management data allows for strategic procurement, avoiding expedited shipping costs and extended downtime, which is invaluable for managing risk and resources.

More info about Reinvigorating Hydropower

Leveraging Operational Flexibility and Market Expectations

Combining technical decisions with market strategy is where hydropower asset management excels. Hydropower’s flexibility is a commercial advantage in volatile markets, creating value through ancillary services and optimized generation timing.

Outage management is a strategic tool. Major refurbishments should be scheduled during periods of low expected power prices. This minimizes lost revenue and can reduce project costs, improving overall profitability.

Forward power price expectations also guide investment timing. If prices are projected to rise, accelerating efficiency upgrades can capture more value. If prices are projected to be low, non-critical investments might be deferred, while always maintaining safety and reliability.

The key is integrating market dynamics into your asset management framework. Condition assessments show what needs doing; market expectations help determine when to do it for maximum value. This transforms hydropower asset management from maintenance into a value creation strategy.

Practical guidance from the World Bank

The Future of Hydropower Asset Management: Innovation and Value Creation

The future of hydropower asset management is about predicting, preventing, and optimizing operations. Digital innovations like predictive maintenance, sensor-driven optimization, and AI-powered analytics are becoming essential tools.

In practice, this means using real-time sensor data to predict a component’s remaining lifetime instead of waiting for scheduled inspections. This shift from time-based to condition-based, prognostics-driven maintenance is revolutionary, improving reliability, availability, resource use, and profitability.

As the electricity sector moves toward sustainability, hydropower asset management innovation is key. These advanced approaches prevent failures, reduce environmental impacts, and ensure peak performance. For aging North American assets, these innovations are essential for survival and success.

More info about Hydropower Innovation

Adapting to New Technologies and Methods

Adopting new technologies doesn’t require starting from scratch. Existing CMMS and EAMS systems are foundations that can be integrated with modern data analytics tools, turning them into powerful predictive engines.

This integration allows sensor data to flow into optimization models to predict failures, schedule maintenance economically, and optimize reservoir management. Forward-thinking operators are creating intelligent systems that learn and improve over time.

Prognostics-driven maintenance enables smarter, preventative decisions. Work can be scheduled during low-price periods and long-lead-time equipment ordered proactively, all with data-backed confidence.

The key is to start where you are and build progressively. Even small steps toward digital integration can significantly improve your hydropower asset management program’s effectiveness.

AI-Driven Development insights

Enhancing Value in the Energy Transition

Hydropower asset management open ups hidden value that supports the energy transition. As wind and solar grow, the grid needs hydropower’s reliable, dispatchable power to fill intermittency gaps.

An often-overlooked opportunity is improving flow measurement accuracy. Case studies show this can increase annual generation by 0.4% to 1.8%. Over decades, this translates to substantial revenue increases, often enough to fund other critical improvements.

Beyond flow measurement, strategic asset management improves overall generation efficiency by optimizing turbines and reducing transmission losses. This technical optimization also has environmental benefits, generating more clean electricity from every drop of water.

The energy transition needs hydropower to succeed. By continuously improving the technical, environmental, and water-use efficiency of our existing fleet through smart hydropower asset management, we secure hydropower’s role as a cornerstone of sustainable energy infrastructure.

At FDE Hydro, we know modern asset management and innovative construction go hand in hand. Our modular precast concrete technology helps extend the life and improve the performance of hydropower infrastructure, complementing your asset management program with faster, more cost-effective, long-term construction solutions.

More info about Sustainable Power Generation

Frequently Asked Questions about Hydropower Asset Management

What is the first step in creating a hydropower asset management program?

The first step is to establish clear objectives aligned with your organization’s strategic priorities, such as improving reliability, reducing costs, or extending asset life. Once objectives are defined, conduct a thorough inventory and condition assessment of all assets. This provides a baseline understanding of your equipment’s health, identifying what’s in good shape and what needs attention. You can’t plan a path forward without knowing your starting point.

How does asset management help with aging hydropower infrastructure?

Hydropower asset management provides a structured framework to manage aging infrastructure. Instead of reacting to failures, it allows for systematic condition assessment and risk-based prioritization of repairs and replacements. This proactive approach prevents catastrophic failures, as a planned outage is always better than an emergency shutdown. By justifying investments with data, asset management extends the viable lifespan of facilities, allowing them to operate for over 100 years with proper maintenance.

Can small hydropower plants benefit from a formal asset management program?

Yes. While the scale is different, the fundamental principles of hydropower asset management apply and are highly beneficial for small plants. Smaller facilities often have tighter budgets and smaller teams, making a structured approach even more valuable. A simplified, customized program helps prioritize limited resources effectively. It improves reliability, ensures safety compliance, and maximizes revenue by changing operations from reactive to strategic, making the plant more sustainable and profitable.

Conclusion

Hydropower asset management is about changing hydroelectric facilities from aging cost centers into strategic, value-creating assets. By establishing robust programs (using frameworks like ISO 55000), prioritizing critical assets, using condition assessments for smart decisions, and justifying investments with analytical tools, we can move from a reactive maintenance cycle to a powerful, sustainable approach.

The stakes are high. With aging equipment and hydropower’s vital role in grid stability, old operational methods are no longer sufficient. By applying strategic hydropower asset management, facilities can operate reliably for over a century, adapting to evolving market demands.

Technology is revolutionizing what’s possible. Tools like predictive maintenance, sensor-driven optimization, and AI-powered analytics are available now to prevent failures, optimize real-time performance, and maximize asset value while minimizing environmental impact.

At FDE Hydro™, we combine smart asset management with innovative construction. Our patented modular precast concrete technology, the “French Dam,” addresses aging infrastructure and new development needs in North America, Brazil, and Europe. By reducing construction costs and timelines, we help operators implement critical capital improvements identified by their asset management programs, building resilient, efficient facilities for future generations.

The journey from reactive maintenance to strategic value creation is worthwhile. The principles—understand your assets, prioritize based on data, invest strategically, and continuously optimize—apply to any size operation. Together, we can ensure hydropower remains a cornerstone of clean, reliable energy.

Learn how to finance long-term hydropower projects by mitigating risks