Why Hydroelectric Dam Efficiency Matters More Than Ever

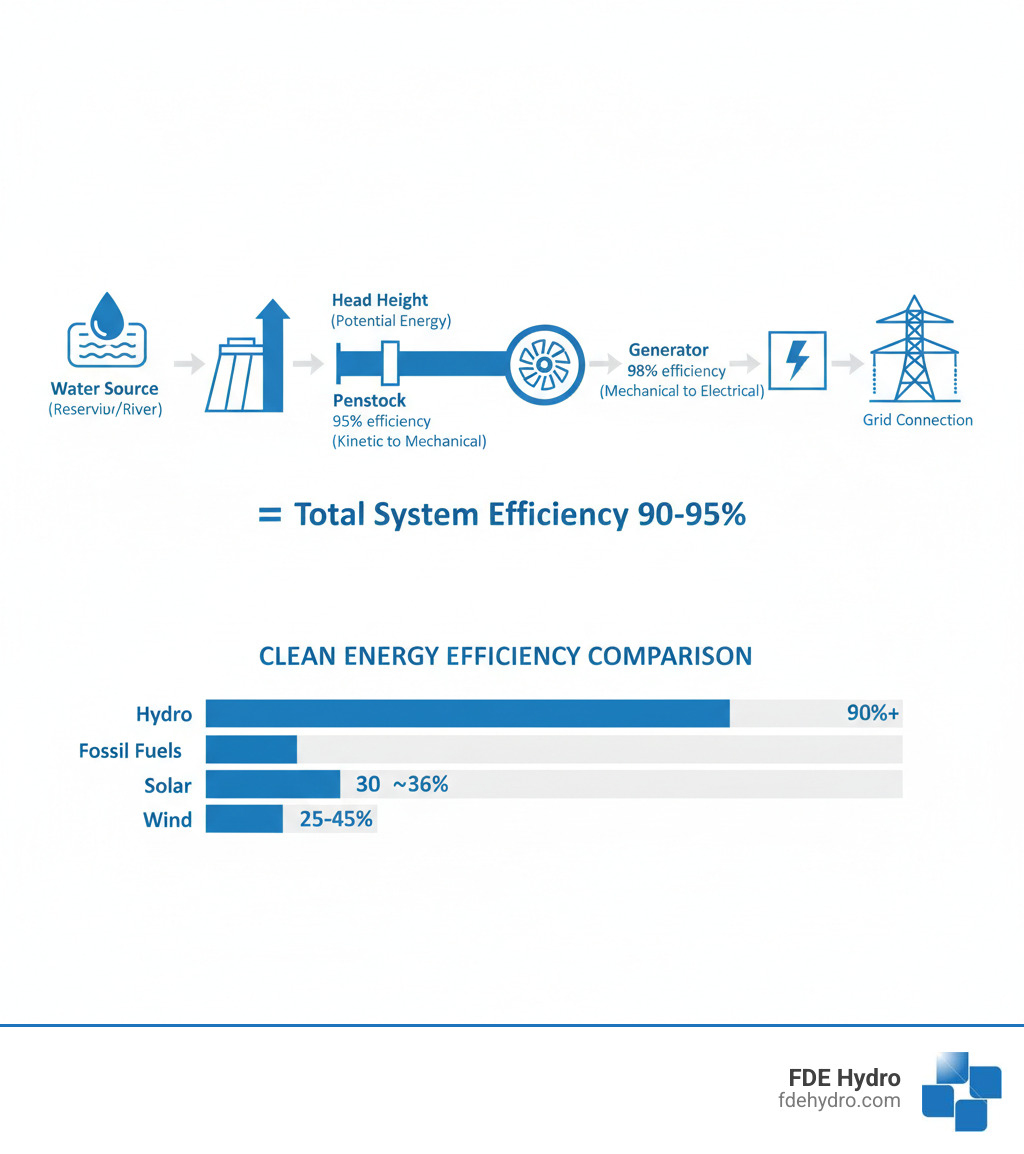

Hydroelectric dam efficiency measures how effectively a facility converts water’s potential energy into electricity, with conversion rates often exceeding 90%. Peak performance depends on factors like turbine design, hydraulic head (water drop), flow rate, system losses, and maintenance. Understanding these is critical because a 5-10% efficiency gain directly increases power output and revenue without building new capacity.

Global hydropower supplies 15-17% of the world’s electricity with efficiency that far surpasses solar (30-36%), wind (25-45%), and fossil fuels (~60%). Optimizing existing infrastructure is one of the most cost-effective paths to clean energy expansion. However, with most plants in North America and Europe averaging 45-50 years old, aging components leave significant performance gains on the table. Much of the world’s 4,100 TWh of realized hydropower operates below its potential.

I’m Bill French Sr., Founder and CEO of FDE Hydro™. After five decades in heavy civil construction, I’ve spent the last ten years revolutionizing the hydropower industry with modular construction. My work with the Department of Energy’s Water Power Technology Office has provided deep insight into maximizing hydroelectric dam efficiency through modernization. Let’s explore how to open up your hydropower assets’ full potential.

Understanding the Fundamentals of Hydroelectric Dam Efficiency

Hydropower harnesses gravity and moving water, converting the potential energy of water at a higher elevation into electricity. The governing formula is P = ηρgQH, which outlines how water becomes watts.

In this equation, η (eta) is the hydroelectric dam efficiency—the percentage of energy converted, typically 90-95% (0.9-0.95). The other variables are largely constant: ρ (rho) is water density (~1000 kg/m³) and g is gravity’s acceleration (9.8 m/s²). The key variables operators can influence are Q, the flow rate in cubic meters per second, and H, the hydraulic head—the vertical distance the water falls. Improving any of these, especially efficiency, directly boosts power output.

This efficiency gives hydropower an incredible energy payback ratio. Facilities can produce 200 to 300 times more energy than is required to build and operate them, the highest of any renewable source. For more on these principles, the Department of Energy offers excellent Hydropower Basics resources.

How Hydropower’s Efficiency Stacks Up

When it comes to energy conversion, hydropower is the undisputed champion, converting over 90% of available energy into electricity. In comparison, other technologies lag significantly. Solar panels reach about 30-36% efficiency, converting photons to electrons while losing most energy as heat. Wind turbines perform at 25-45%, limited by aerodynamics and unpredictable wind. Even modern fossil fuel plants only achieve around 60% efficiency, with nearly half the fuel’s energy lost as waste heat. Hydropower’s 90%+ efficiency means more clean electricity per drop, better economics, and a smaller environmental footprint per kilowatt-hour.

The Physics of Power: The Role of Head and Flow

Water in a reservoir holds potential energy. The higher the water is stored above the turbines, the more potential energy it contains. When released through a penstock, this potential energy converts into kinetic energy—the energy of motion. This forceful, fast-moving water spins the turbine blades, which in turn drives the generator to produce electricity.

The hydraulic head (the vertical drop) is critical; a 300-foot head generates far more power per gallon than a 30-foot head with the same flow. However, head alone is not enough. Flow rate—the volume of water moving through the system—is equally important. The greatest power is achieved by balancing both factors. This is why site selection and design are crucial for maximizing hydroelectric dam efficiency.

At FDE Hydro, our modular construction approach ensures water flows smoothly to minimize energy loss. To see how modern design optimizes this potential, check out More info about Dams.

Key Factors That Influence a Dam’s Performance

While the physics are straightforward, a dam’s real-world performance depends on many interconnected factors. The hydroelectric dam efficiency achieved daily is a function of how well every component works together, from turbine design and generator efficiency to penstock friction and operational constraints imposed by grid demand or environmental rules.

The Critical Role of Turbine Design and Selection

The turbine is the heart of a hydro plant, where water’s kinetic energy becomes mechanical power. The right turbine selection is a site-specific design challenge that is critical for maximizing output. There is no one-size-fits-all solution:

- Pelton turbines are ideal for high-head (over 200m), low-flow sites, using powerful jets of water to spin a bucketed wheel.

- Francis turbines are the industry workhorses, versatile enough for moderate heads (30-600m) and a wide range of flow rates. They are reaction turbines where water pressure drops as it passes through the blades.

- Kaplan turbines excel in low-head (up to 30m), high-flow conditions, like those found in rivers. Their adjustable propeller-like blades maintain high efficiency even when flow rates fluctuate.

Modern turbines, benefiting from advanced modeling and materials, can achieve 95% efficiency. Older turbines, while durable, cannot match this performance, creating a significant opportunity for efficiency gains through refurbishment or replacement, which can often boost output by 5-10%.

How Environmental Factors Affect Achievable Efficiency

Environmental realities also impact a facility’s performance. Sedimentation is a primary culprit; as rivers deposit sand and silt, this silt buildup causes reduced reservoir capacity and less water for generation. As noted in scientific research, these abrasive particles also erode turbine components, degrading performance and requiring costly maintenance.

Drought conditions pose another major challenge. Lower rainfall leads to reduced reservoir levels, which decreases the hydraulic head and inflows, causing power output to plummet. Water temperature variations can also subtly influence performance.

Furthermore, modern facilities must balance generation with environmental duties, such as ensuring fish passage and maintaining minimum downstream flows. While fish mortality is a real concern, innovations like fish-friendly turbines and bypass systems help protect aquatic life while maintaining strong generation. It’s about balancing clean energy with environmental stewardship. Learn more about how the industry is addressing these issues at More info about Aquatic Animal and Recreational Passage.

How to Improve and Maximize Dam Efficiency

Fortunately, there are proven strategies to boost hydroelectric dam efficiency in existing plants. Modernization combines physical upgrades with digital tools, allowing us to gain substantial efficiency without the cost and impact of building new dams. This involves everything from replacing worn components to implementing predictive monitoring systems.

Upgrading Core Components for Better Hydroelectric Dam Efficiency

Replacing aging parts with modern equivalents delivers remarkable improvements in hydroelectric dam efficiency.

- Turbine runner replacement is often the most impactful upgrade. Modern runners, designed with advanced fluid dynamics, can increase energy production by 5-10%. A 5% gain at a 100 MW plant adds 5 MW of clean power from the same water flow.

- Advanced coatings protect components from abrasion. Nanostructured coatings can withstand sediment-laden water, extending component life and maintaining peak efficiency, a field advanced by scientific research on sediment erosion in turbines.

- Wicket gate refurbishment is also key. These gates control water flow to the turbine. Repairing or replacing worn gates ensures precise water delivery, maximizing energy extraction.

Leveraging Digitalization and Smart Operations

Digitalization is the other half of the modernization equation, bringing 21st-century intelligence to mid-20th-century facilities.

- Digital twins, virtual replicas of a plant fed by real-time sensor data, allow operators to monitor performance, simulate scenarios, and predict failures without risk.

- AI-powered forecasting analyzes weather and hydrological data to predict water availability with high accuracy, enabling smarter decisions on when to generate or store water.

- Real-time optimization uses modern control systems to continuously adjust operations to maximize efficiency based on current conditions and grid prices.

- SCADA systems (Supervisory Control and Data Acquisition) provide centralized remote monitoring and control, forming the nervous system of an intelligent hydropower operation.

This comprehensive approach is central to Reinvigorating Hydropower for a new era, ensuring these facilities deliver clean energy for generations.

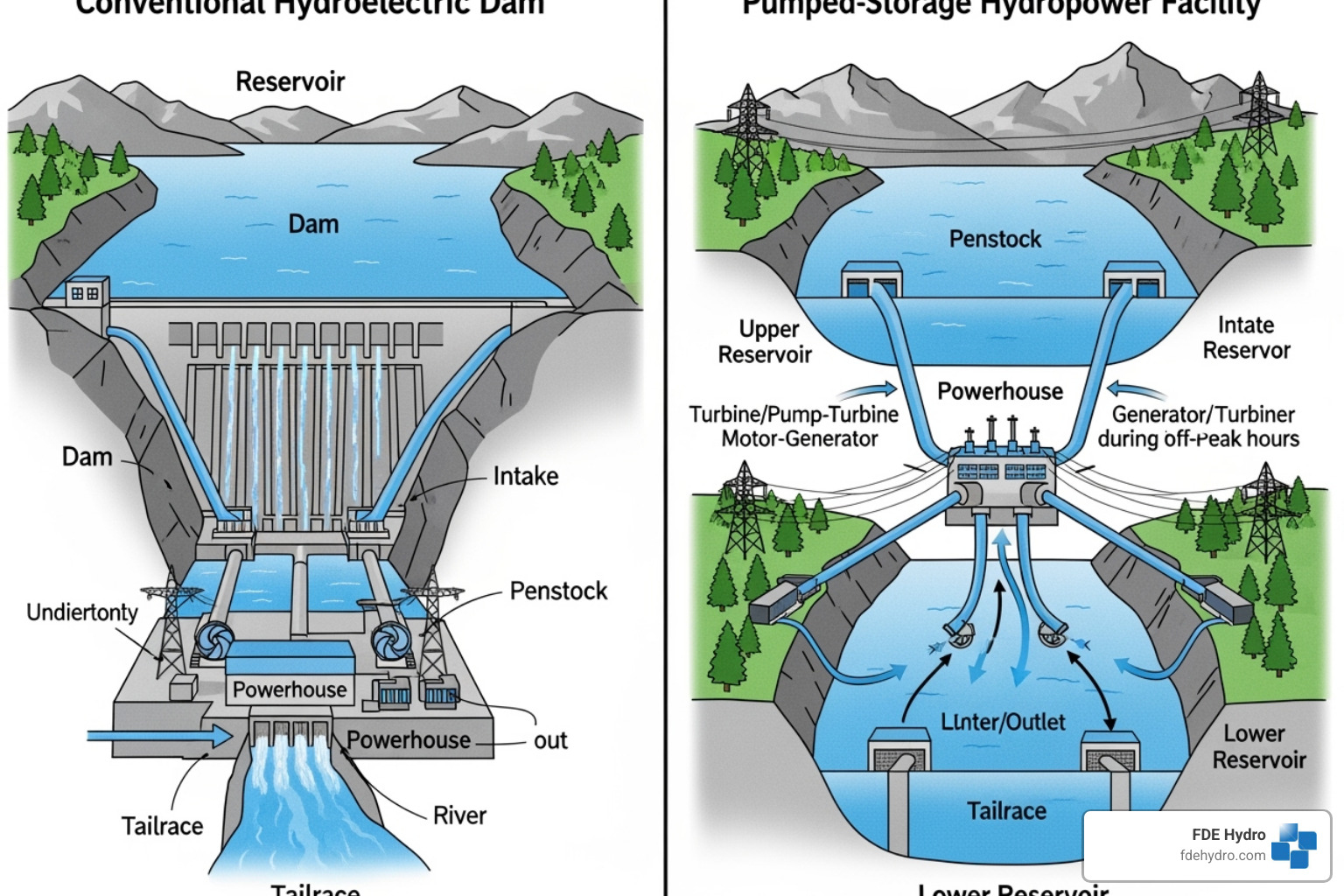

The Efficiency Equation: Conventional vs. Pumped-Storage Hydropower

When discussing hydroelectric dam efficiency, it’s important to distinguish between two facility types that serve different grid purposes: conventional and pumped-storage hydropower.

Conventional hydropower harnesses the natural flow of rivers. Run-of-river systems divert a portion of a river through turbines with minimal storage, while impoundment systems use large reservoirs to store water and dispatch power on demand. Both are designed to convert flowing water into electricity with the impressive 90-95% water-to-wire efficiency discussed earlier.

Pumped-storage hydropower (PSH), in contrast, acts as a giant, rechargeable battery for the grid. It uses two reservoirs at different elevations. During times of low electricity demand and cost, excess grid power (often from wind or solar) is used to pump water from the lower reservoir to the upper one. When demand peaks, the water is released back down through turbines to generate electricity.

This energy storage and grid balancing capability is crucial for integrating intermittent renewables like solar and wind. PSH accounts for over 95% of global grid-based energy storage, making it a workhorse technology. For more details, see More info about Pumped Storage Hydropower.

Understanding Pumped Storage Round-Trip Efficiency

Since PSH is an energy storage system, its performance is measured by round-trip efficiency—how much energy is returned compared to what was used to store it. The process involves two phases:

- Pumping phase: Electricity from the grid powers pumps to move water uphill. Energy is lost to friction and mechanical inefficiencies.

- Generation phase: Stored water flows downhill through turbines to generate electricity, with further energy losses from turbine and generator friction.

Modern PSH facilities achieve a round-trip efficiency of 70-85%. While lower than conventional hydro’s 90%+, this is exceptional for large-scale storage. The 15-30% energy loss is the cost of having gigawatt-scale power available on demand.

Beyond storage, PSH provides vital ancillary services like frequency regulation and voltage support, acting as a shock absorber that ensures grid stability. As renewables grow, these services become priceless for maintaining a reliable grid.

The Economic and Future Outlook of High-Efficiency Hydropower

Higher hydroelectric dam efficiency is an economic powerhouse. Hydropower’s Levelized Cost of Energy (LCOE) of 2-10 US cents per kWh makes it one of the most affordable energy sources. With lifespans of 65-85 years or more and low operation and maintenance (O&M) costs, these facilities provide reliable, dispatchable power that is a cornerstone of a stable energy grid. For the latest advancements, the National Renewable Energy Laboratory Hydropower Research is an excellent resource.

Economic Implications of Improving Hydroelectric Dam Efficiency

Even modest efficiency improvements create substantial economic benefits. A 5-10% gain in hydroelectric dam efficiency leads to:

- Increased revenue: More electricity is generated and sold from the same amount of water, directly boosting the bottom line.

- Lower electricity costs: Higher efficiency at the source can lead to lower costs per kWh for consumers.

- Extended asset life: Smoother, more efficient operations reduce strain on equipment, deferring major capital expenditures.

- Stronger return on investment: The combination of higher revenue, lower costs, and longer asset life makes hydropower projects more attractive to investors.

Innovations Shaping the Future of Hydropower

The future of hydropower is being shaped by innovations that push hydroelectric dam efficiency higher while addressing environmental concerns.

- Variable-speed turbines adjust their rotational speed to match changing water flows, maintaining peak efficiency across a wider range of conditions.

- Fish-friendly designs use features like wider blade spacing and slower speeds to allow fish to pass through turbines with significantly reduced injury rates.

- Modular construction, an area where FDE Hydro™ is a leader, is revolutionizing how facilities are built and retrofitted. Our patented “French Dam” technology uses pre-fabricated concrete modules that drastically cut construction time and costs. This U.S. Department of Energy-endorsed approach makes new projects more viable and accelerates upgrades. This modularity also extends to our Modular Powerhouses, streamlining the entire construction process.

Conclusion: Powering the Future with Optimized Hydropower

Our journey through hydroelectric dam efficiency reveals a clear truth: this is about using one of nature’s most reliable forces to power our world with clean, affordable energy. Hydropower’s remarkable 90%+ efficiency far outpaces other renewables, making it an irreplaceable cornerstone of a clean energy strategy.

The challenges of aging infrastructure are not roadblocks but opportunities. Every efficiency improvement, from a turbine upgrade to AI-powered forecasting, open ups more clean energy from existing assets. Pumped-storage hydro further demonstrates this versatility, providing the large-scale energy storage needed to support the growth of wind and solar with 70-85% round-trip efficiency.

Innovations like variable-speed turbines and fish-friendly designs are pushing the industry forward. At FDE Hydro™, we are revolutionizing the field with our patented modular construction technology. By slashing construction time and costs, we make hydropower projects more viable and accelerate the modernization of existing facilities.

With a low levelized cost, long lifespan, and an incredible energy payback ratio, improving hydroelectric dam efficiency is one of the smartest investments we can make. It boosts revenue, extends asset life, and strengthens our grid. The global potential for hydropower is vast, and optimizing our current fleet is the first step to realizing it.

We invite you to learn more about our advanced Dam technology and see how we’re building the future of hydropower. Together, we can open up the full potential of this remarkable resource for generations to come.