Why Dam Construction Methods Matter for Modern Infrastructure

Dam construction methods have evolved from ancient earthen barriers to sophisticated projects that power nations. Understanding these methods is key for new hydropower facilities or rehabilitating aging infrastructure.

Primary Dam Construction Methods:

- Embankment Dam Construction – Building with compacted earth or rock in layers (75% of all dams worldwide)

- Concrete Dam Construction – Pouring reinforced concrete using traditional formwork or Roller-Compacted Concrete (RCC)

- Modular Precast Construction – Assembling factory-built components on-site (emerging innovation)

Key Construction Phases:

- River Diversion – Using cofferdams or tunnels to create a dry work area

- Foundation Preparation – Excavating to bedrock, grouting, and building the plinth

- Dam Structure Assembly – Placing materials in controlled lifts or layers

- Component Installation – Adding spillways, outlet works, and powerhouses

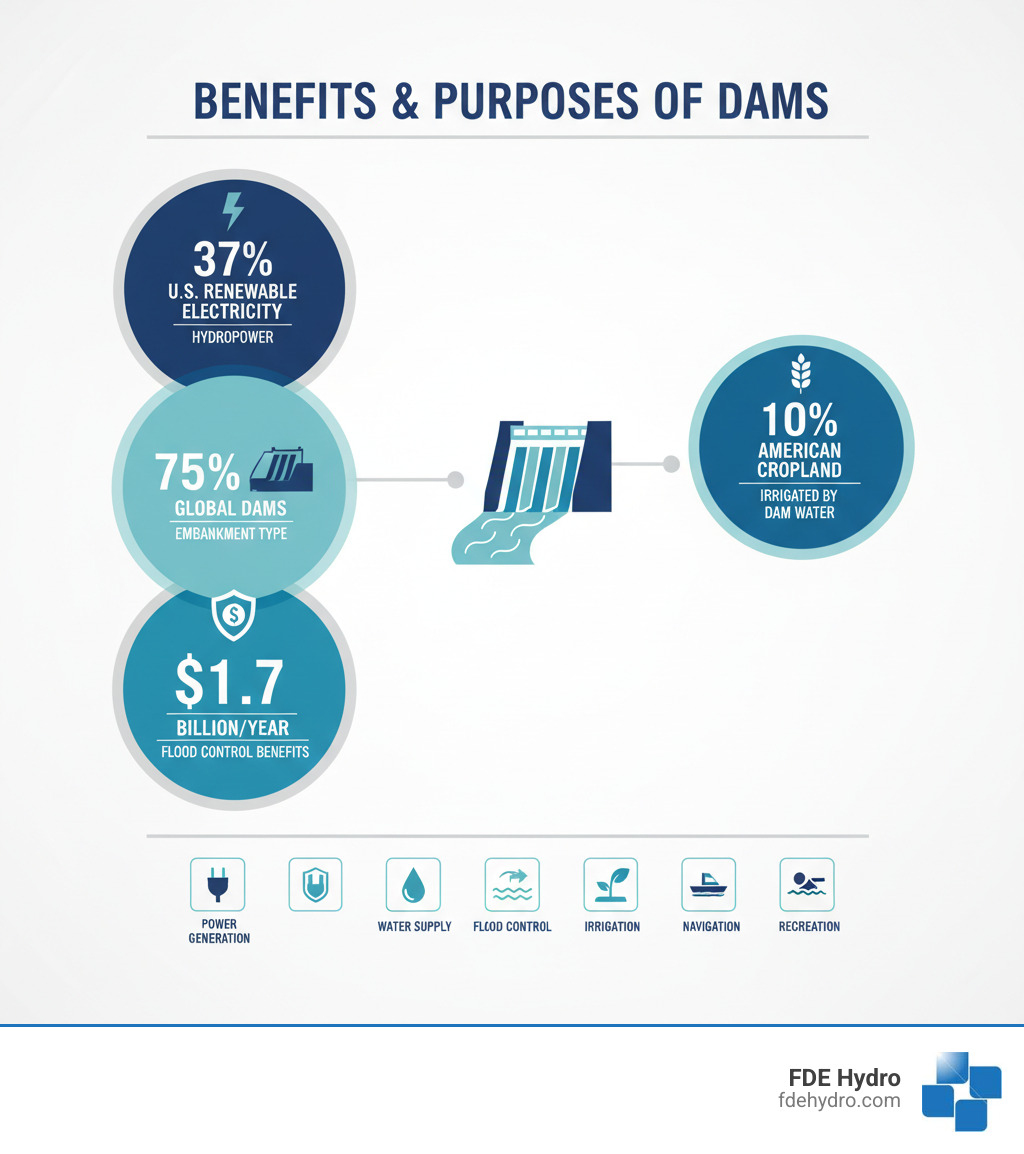

Dams are critical for hydropower, flood control, irrigation, and water supply. Globally, there are over 800,000 dams, but traditional dam construction methods face challenges from climate change, long timelines, and high costs, driving the need for innovation.

Construction begins with site selection, followed by river diversion, foundation preparation, and building the structure. Each phase demands precision to ensure the dam can withstand immense pressure and environmental forces for decades.

I’m Bill French Sr., Founder and CEO of FDE Hydro. With five decades of heavy civil construction experience, I specialize in advancing dam construction methods through modular precast technology. This guide combines traditional principles with emerging innovations to steer modern dam construction.

The Blueprint: Classifying Dams and Choosing the Right Design

Choosing a dam design is like selecting a foundation for a house, but with much higher stakes. A site’s geology, topography, and available materials dictate the most effective dam construction methods and design.

Dams are critical infrastructure. In 2022, hydropower provided nearly 37% of all U.S. clean, renewable energy. Beyond power, dams offer billions in annual benefits from flood control, water supply, and irrigation for ten percent of American cropland.

The right dam type depends on a balance of site selection criteria. A narrow canyon with solid rock walls suits a different design than a wide river valley.

Embankment Dams: The Global Standard

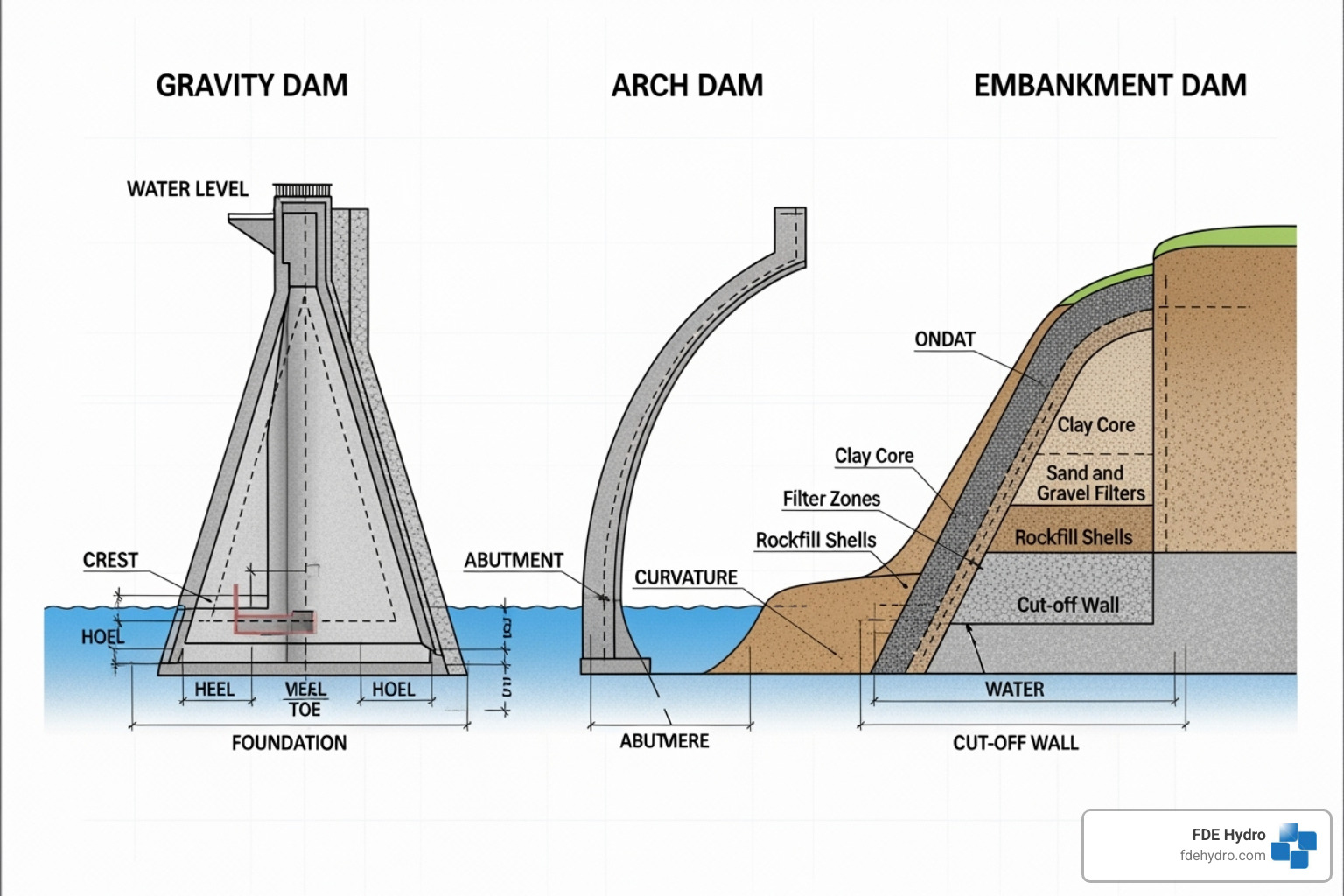

Embankment dams comprise 75% of all dams worldwide due to their adaptability and use of local materials. They are massive structures of compacted earth and rock that rely on their mass weight resistance to hold back water. Construction involves building them layer by layer, with precise compaction methods for each layer to ensure stability.

- Earth-fill dams use soil and clay with an impermeable core to prevent seepage.

- Rock-fill dams use quarried rock with a watertight barrier, such as a concrete face or an internal core, along with filter and drainage systems to control seepage.

Concrete Dams: Monuments of Strength

Concrete dams are rigid structures where geometry is as important as mass in managing immense water forces.

- Gravity dams use their enormous weight to resist water pressure and require strong foundations, like the famous Hoover Dam.

- Arch dams are curved to transfer water pressure horizontally into the canyon walls (abutments), allowing for a thinner, more efficient structure. The curved geometry is key to how Arch Dam Forces work.

- Buttress dams use a series of supports to brace a thin upstream slab, saving on concrete compared to gravity dams.

Roller-Compacted Concrete (RCC) has transformed concrete dam construction. This method involves compacting a dry concrete mix in layers, which speeds up construction, reduces costs, and minimizes heat buildup during curing.

At FDE Hydro, we are dedicated to advancing how we build and rehabilitate Dams, bringing innovation to all approaches.

Key Factors Influencing Dam Design

Selecting the right dam design requires weighing several factors:

- Topography often dictates the initial choice. Narrow gorges may suit an arch dam, while wide valleys are better for embankment or gravity dams.

- Geology and foundation stability are non-negotiable. Weak ground must be removed or treated before construction.

- Material availability directly impacts cost and design choice. On-site earth and rock favor embankment dams.

- The project purpose—hydropower, flood control, or irrigation—shapes the dam’s height and features.

- The design must be engineered to withstand forces like water pressure, uplift, and seismic activity.

- Economic and logistical factors, including cost and site access, are crucial practical considerations.

Our mission is to create robust Water Control Structures that serve communities safely for generations.

A Step-by-Step Guide to Traditional Dam Construction Methods

Building a dam follows a fundamental sequence, even with modern technology. The process relies on extensive geotechnical investigation, material testing, and heavy machinery to move earth and pour concrete.

Phase 1: Site Preparation and River Diversion

The first phase is dewatering and river diversion. Since you can’t build in a flowing river, the water is rerouted using diversion tunnels, channels, or temporary barriers called cofferdams. Once the work area is dry, crews begin foundation excavation, digging and sometimes blasting down to stable bedrock.

Phase 2: Laying a Stable Foundation

The second phase is creating a stable foundation. After excavation, loose rock is removed, and the bedrock is strengthened and sealed through grouting—injecting a cement mixture into cracks. A concrete plinth may be built to create a level base. Foundation requirements vary by dam type; gravity dams need strong bedrock, while arch dams need solid canyon walls.

Phase 3: Building the Dam Structure – A Comparison of dam construction methods

Phase three is building the dam structure, where dam construction methods for concrete and embankment dams differ.

| Feature | Concrete Dam Construction | Embankment Dam Construction |

|---|---|---|

| Materials | Concrete, aggregate, cement, reinforcing steel | Earth, clay, sand, gravel, rock fill |

| Best Site Conditions | Narrow valleys with strong bedrock | Wide valleys, variable foundation conditions |

| Construction Speed | Slower (curing time required between lifts) | Faster (weather-dependent) |

| Cost | Higher material costs, lower labor for placement | Lower material costs if available locally, higher labor |

For concrete dam construction, concrete is poured into formwork in layers called lifts, with time for curing between each pour. Roller-Compacted Concrete (RCC) speeds up this process, as a drier mix can be spread and compacted quickly.

For embankment dam construction, earth or rock is placed and compacted in layers using heavy rollers. An impermeable core of clay or concrete prevents seepage and is protected by surrounding filter and drainage zones.

Phase 4: Installing Essential Components

The final phase is installing essential components for water control and power generation.

- Spillways act as safety valves to release excess water during floods, preventing the dam from overtopping. We design various types of Spillways to handle the maximum probable flood.

- Outlet works are conduits with gates or valves that allow for controlled water releases for supply or maintenance.

- Penstocks are large pipes that carry water under high pressure to the turbines in hydroelectric facilities.

- Powerhouses contain the turbines and generators that produce clean, renewable Hydropower. We also specialize in innovative Modular Powerhouses.

The installation of these components must be carefully sequenced with the main construction. Understanding these traditional methods provides a foundation for appreciating the need for innovative Water Control Structures.

Modern Challenges: Climate Change and Dam Safety

Traditional dam construction methods face new challenges from a changing climate, requiring a shift in how we design, build, and manage these critical structures.

The Impact of a Changing Climate

Climate change makes outdated historical data unreliable for dam design. We now see more unpredictable hydrological cycles, leading to extremes of both flooding and drought. This increased flooding risk forces upgrades like the expanded spillway at Folsom Dam, while water stress from drought impacts water supply and power generation.

Environmental Impacts and Mitigation Measures

Dams have significant environmental impacts. They create altered river ecosystems, trap sediment needed downstream, and create fish migration barriers. To mitigate these effects, modern dams incorporate strategies like:

- Fish ladders and bypass systems to help species steer around the structure.

- Environmental flow releases to mimic natural river patterns.

- Sediment management techniques to allow controlled passage of sediment.

These measures help balance human water demands with the needs of riverine ecosystems.

Ensuring Long-Term Safety and Regulation

Dam safety is paramount, as a failure is catastrophic. Common dam failure modes include overtopping (see a video example of its destructive power), foundation failure, and internal erosion. To prevent this, dams are equipped with extensive instrumentation for rigorous monitoring practices to track pressure, seepage, and movement.

Strict safety regulations provide a framework for accountability. In the U.S., the National Inventory of Dams (NID) catalogs dams, most of which are regulated at the state level. Public resources like the Living Near Dams Booklets also help inform communities about potential risks.

The Future of Dam Building: Innovation and Sustainability

Climate change challenges are driving innovation in dam construction methods, pushing the industry toward smarter, more sustainable infrastructure.

Emerging Technologies in dam construction methods

The industry is undergoing a technological renaissance. Innovations include:

- Advanced materials like stronger, more durable, and even self-healing concrete.

- ICT-driven construction using GPS-guided machinery and real-time data analytics for improved quality control.

- Automated monitoring systems using AI and drones to detect potential issues early.

- Smarter, fish-friendly turbine designs for Reinvigorating Hydropower projects.

Modular Precast Construction: A Paradigm Shift

At FDE Hydro, we are pioneering modular precast construction, a approach that moves most construction from the project site to a controlled factory setting. Our innovative French Dam technology involves manufacturing high-quality concrete components off-site while the foundation is prepared. This leads to significant benefits:

- Reduced Construction Time: As demonstrated by our recent Prototype of Modular Precast French Dam Completed, projects can be finished in a fraction of the traditional time.

- Lower Costs: Factory production, reduced on-site labor, and fewer weather delays are Why Precast Cost Less.

- Improved Quality Control: Manufacturing in a controlled environment ensures every component meets exact specifications for superior durability.

- Minimized Environmental Footprint: Shorter on-site construction means less disruption to local ecosystems.

Designing for Resilience and Rehabilitation

Designing for resilience is now standard practice. This includes over-installing for future capacity and using adaptive management strategies. Retrofitting aging dams is also a major opportunity. Our specialized solutions for Dam Rehabilitation & Encapsulation improve the safety and performance of existing infrastructure, making it more resilient for the future.

The future of dam construction is about enhancing proven principles with modern technology. For more information, explore our Means and Methods.

Frequently Asked Questions about Dam Construction

Here are answers to some frequently asked questions about dam construction methods.

What are the 3 main types of dams?

The three main types are embankment, gravity, and arch dams. Embankment dams, the most common type, are made from compacted earth and rock. Gravity dams are massive concrete structures that rely on their own weight for stability. Arch dams are curved concrete structures that transfer water pressure to the canyon walls, allowing for a thinner design.

What are the basic steps to build a dam?

The basic steps to build a dam are:

- River Diversion: Reroute the river around the construction site using cofferdams or tunnels to create a dry work area.

- Foundation Preparation: Excavate down to solid bedrock and treat it to ensure a stable, watertight base.

- Dam Construction: Build the main structure by either placing and compacting layers of earth/rock (embankment) or pouring concrete in lifts (concrete).

- Component Installation: Install spillways, outlet works, and powerhouses to make the dam operational.

Why is dam safety so important?

Dam safety is critical because a failure can be catastrophic, causing loss of life and widespread destruction. Dams must withstand immense forces over a long lifespan. For this reason, design, construction, and ongoing monitoring are subject to rigorous standards. Innovations in dam construction methods, such as modular precast technology, improve safety by creating more durable and resilient structures designed to protect communities for generations to come.

Conclusion

From ancient earthen mounds to modern engineering marvels, dam construction methods have continuously evolved. Today, traditional methods face new pressures from climate change, long timelines, and high costs, making innovation essential.

Modular precast construction offers a path forward. By manufacturing components in a factory, we can build dams faster, more affordably, and with superior quality control, all while minimizing environmental disruption. This approach represents a significant shift toward more sustainable and resilient infrastructure.

At FDE Hydro, our “French Dam” technology embodies this innovative spirit. We combine proven engineering principles with modern methods to create adaptable water control structures that meet the challenges of tomorrow. The future of hydropower depends on building smarter, not just bigger.

We invite you to explore how these innovations can benefit your next project. Learn more about our innovative Means and Methods and find how we are shaping a more resilient future through advanced dam construction methods.