Why Innovative Precast Concrete Matters for Modern Infrastructure

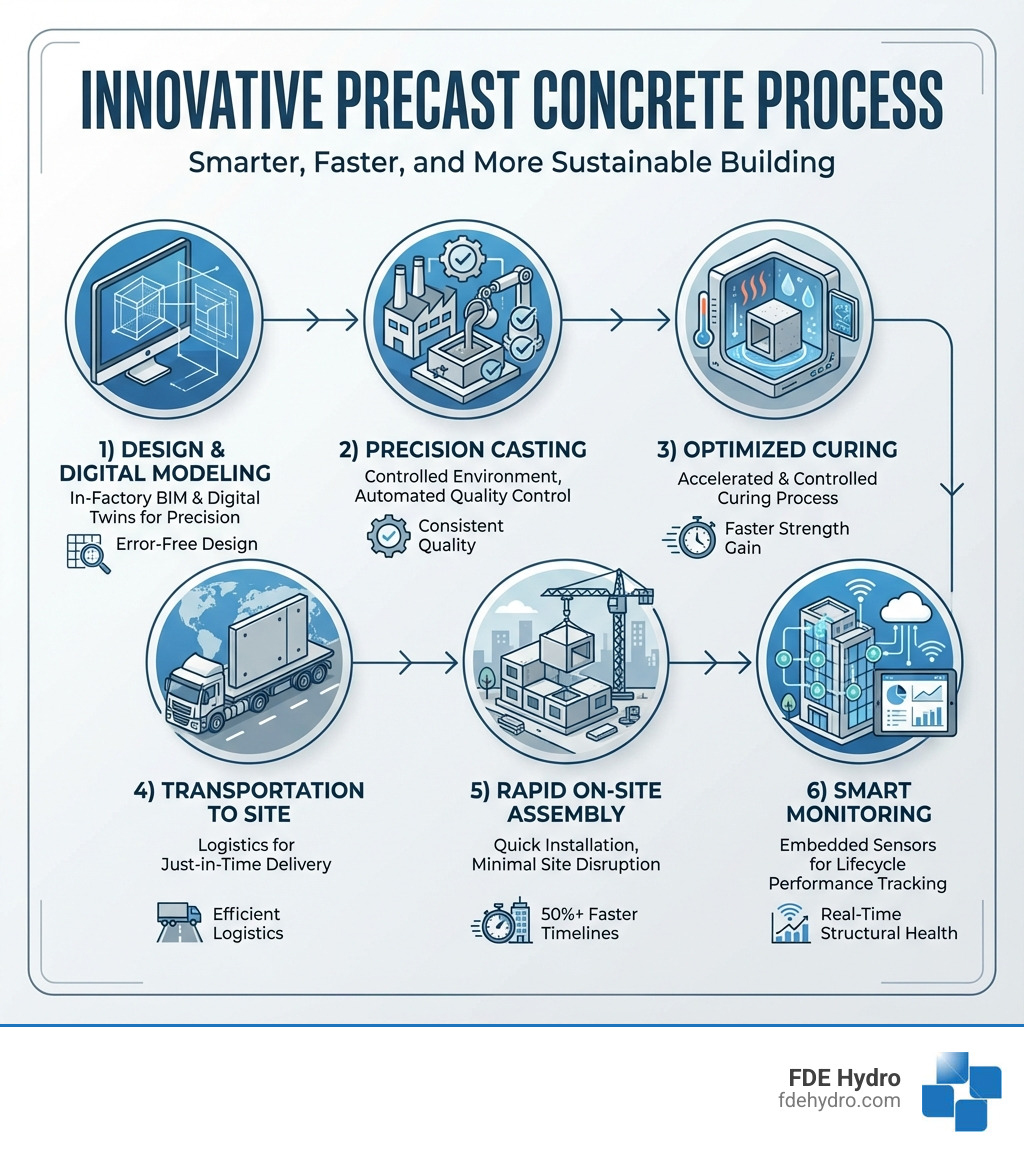

Innovative precast concrete is revolutionizing how we build by manufacturing concrete elements off-site in controlled factory environments, then assembling them rapidly on location. This approach delivers faster construction timelines, superior quality control, and improved sustainability compared to traditional methods.

Key innovations changing precast concrete today:

- Smart Technology Integration – Embedded sensors and IoT devices monitor structural health in real-time

- Modular Systems – Off-site fabrication enables rapid assembly and scalability for large projects

- Sustainable Mix Designs – Recycled materials and CO2 injection reduce carbon footprint by up to 30%

- Digital Fabrication – BIM and digital twin technology optimize design and eliminate errors

- Advanced Materials – High-performance insulated panels deliver superior energy efficiency

- Faster Timelines – Parallel processing cuts construction schedules by 50% or more

The numbers tell a compelling story. With 1,939 precast concrete manufacturing businesses operating in the U.S. and the global market projected to reach $168.17 billion by 2026, this construction method has moved from niche to mainstream. Modern projects demand speed, precision, and sustainability—and innovative precast concrete delivers on all three fronts.

The construction industry faces mounting pressure. Traditional cast-in-place methods struggle with weather delays, inconsistent quality, extended timelines, and rising labor costs. Meanwhile, infrastructure needs grow more urgent. Innovative precast concrete addresses these challenges head-on through factory-controlled manufacturing, where concrete elements cure under optimal conditions, and modular assembly, where components arrive ready to install.

What makes precast “innovative” today goes far beyond simply pouring concrete off-site. Modern precast incorporates cutting-edge technology at every stage—from digital modeling that catches design conflicts before production begins, to smart sensors embedded within panels that monitor performance for decades. These advances transform concrete from a passive building material into an intelligent, responsive system.

The benefits extend across multiple dimensions. Speed: Projects that once took months now complete in weeks. Quality: Factory conditions produce consistent results that exceed industry certification standards. Durability: Precast concrete withstands extreme conditions including freeze-thaw cycles, fire, floods, and seismic events. Sustainability: Reduced waste, lower emissions, and energy-efficient thermal properties support green building goals.

For large-scale infrastructure projects—particularly in water control systems, bridges, and hydropower facilities—innovative precast concrete offers a transformative solution. The modular approach reduces capital expenditure, accelerates delivery timelines, and minimizes the financial and operational risks inherent in conventional construction.

I’m Bill French Sr., Founder and CEO of FDE Hydro, where we’ve pioneered patented modular precast concrete solutions specifically for the hydropower industry, including our approach to natural run-of-river hydro facilities and water control systems. My five decades in heavy civil construction, including landmark projects utilizing modular precast bridge construction, have shown me how innovative precast concrete transforms project outcomes—delivering superior results faster, safer, and more sustainably than traditional methods.

Common innovative precast concrete vocab:

Core Advantages: Why Innovative Precast Concrete is Reshaping Construction

When we talk about innovative precast concrete, we’re discussing a fundamental shift in how construction projects are conceived and executed. This isn’t just about efficiency; it’s about building better, stronger, and more sustainably. Our experience has shown us that this method brings unparalleled benefits, from accelerating project timelines to ensuring a superior, lasting quality. It offers architects and engineers incredible design freedom while providing resilience against the harshest environmental conditions. You can explore more about these advantages on our page dedicated to Precast Concrete Advantages.

Best Speed and Efficiency

Imagine a construction site that runs like a well-oiled machine, largely free from the unpredictable delays of weather or labor shortages. That’s the reality with innovative precast concrete. Our elements are manufactured off-site in controlled factory environments, allowing for parallel processing—meaning while site preparation is underway, the building components are already being created. This significantly reduces on-site construction time and lowers labor costs, especially crucial in regions like North America, Brazil, and Europe where skilled labor can be scarce or expensive.

This off-site approach means we’re not battling the elements; whether it’s a New York winter or a Brazilian rainy season, fabrication continues uninterrupted. This all-weather capability ensures consistent production schedules. Once the precast elements arrive on site, assembly is rapid, minimizing disruption to the surrounding environment and communities. For instance, a small, skilled team can assemble vast amounts of infrastructure, with precast wall panels capable of enclosing over 4,000 sq ft per day, per team. Such efficiency is invaluable for projects requiring a quick turnaround, like our work in critical civil infrastructure. Learn more about how we achieve this in our article on Rapid Installment of Module Precast Civil Infrastructure.

Superior Quality and Durability

Quality control is paramount in construction, and here, innovative precast concrete truly shines. Because elements are produced in a factory, every step, from mix design to curing, is carefully controlled. This factory-controlled environment ensures consistent results that often exceed the stringent requirements of PCI (Precast/Prestressed Concrete Institute) Plant Certification. We’re talking about greater impermeability and strength than what’s typically achievable with on-site cast-in-place concrete.

Beyond consistency, precast concrete offers exceptional durability. It can withstand extreme conditions that would challenge other materials, providing robust protection from a wide variety of environmental factors. This includes remarkable resistance to freeze-thaw cycles—a significant advantage for infrastructure in colder climates like Canada or the northern U.S.—as well as superior fire resistance, which increases containment times and improves safety. Its inherent strength also provides excellent security against blast and earthquake events, and outstanding acoustic insulation, making it ideal for a wide range of structures from residential buildings in California to major infrastructure projects in Europe. Find how precast pushes boundaries on our Precast Pushes the Limits of Scale page.

Architectural Freedom and Aesthetics

Gone are the days when concrete was synonymous with drab, gray structures. Today’s innovative precast concrete offers architects and designers virtually unlimited options for aesthetic expression. Architectural precast elements can be crafted with stunning craftsmanship, incorporating a vast array of colors, textures, and forms. Whether the goal is to mimic natural stone, create intricate patterns, or achieve a striking modern aesthetic, precast concrete provides the flexibility to bring even the most ambitious visions to life.

This design freedom extends to complex shapes and custom finishes that would be difficult, if not impossible, to achieve with traditional methods. From the sleek facades of high-rise buildings in New York City to the neat retaining walls in a Kansas campus, precast concrete allows for unique and award-winning designs. It means we’re not just building functional structures; we’re creating beautiful, inspiring environments. Our design process, which emphasizes innovation and creativity, is detailed on our Precast Concrete Design Process page.

The Forefront of Innovative Precast Concrete Technology

The world of innovative precast concrete is constantly evolving, driven by technological advancements that are making our structures smarter, more efficient, and more resilient. We are moving beyond just manufacturing concrete elements off-site; we are embedding intelligence into them, optimizing their design and production through digital tools, and utilizing advanced materials for superior performance. These innovations are reshaping the construction landscape across North America, Brazil, and Europe, ensuring our projects are future-proof. You can dig deeper into these advancements by reading about Innovations and Trends in Precast Concrete Manufacturing & Installation.

Smart Concrete: Embedding Intelligence into Structures

Imagine a bridge that can tell you when it needs maintenance, or a dam that monitors its own structural integrity in real-time. This is the promise of “smart concrete,” a key aspect of innovative precast concrete. By embedding sensors and integrating IoT (Internet of Things) technologies directly into precast elements during manufacturing, we can create structures that are continuously monitored. These smart sensors track critical parameters such as temperature, humidity, stress, strain, and even the formation of micro-cracks.

This real-time structural health monitoring provides invaluable data, enabling predictive maintenance rather than reactive repairs. It means potential issues can be identified and addressed before they become major problems, significantly enhancing safety and extending the longevity of our infrastructure, including vital water control systems. This integration of smart technology transforms precast concrete from a passive material into an active, intelligent component of our built environment. For more information on how smart technology is shaping the future, visit our partners’ insights on innovative precast concrete solutions for smart cities and sustainable growth.

The Role of Innovative Precast Concrete in Digital Fabrication

Digital tools are revolutionizing how we design and produce precast concrete. Our approach leverages digital modeling and Building Information Modeling (BIM) to optimize every stage of a project. BIM is an all-in-one technology that combines digital design, project management, and architecture, creating a cloud-based environment for seamless collaboration among all stakeholders. This allows us to model and manage the design and placement of precast concrete walls, floors, and specialized components with unprecedented precision.

Through BIM, we achieve 3D project visualization, which is far faster and less error-prone than traditional 2D techniques. It enables our design teams to quickly see, manipulate, and adjust projects to meet exact quality, cost, and schedule expectations. Furthermore, digital twin technology allows for the simulation and optimization of precast concrete manufacturing processes, identifying efficiencies and potential issues before physical production even begins. This level of digital fabrication drastically reduces errors, minimizes material waste, and improves overall project control. Explore how we use these advanced models on our Precast Models page.

Advanced Materials and Manufacturing

The quest for stronger, lighter, and more sustainable precast elements drives continuous innovation in materials and manufacturing processes. High-performance insulated panels are a prime example, incorporating advanced insulation materials like expanded polystyrene (EPS) or polyurethane foam to deliver superior thermal performance. These panels are crucial for creating energy-efficient buildings, reducing heating and cooling costs, and contributing to greener structures across diverse climates.

We also see the integration of non-metallic insulation systems, such as advanced fiber composite ties, which improve the structural integrity and thermal performance of precast sandwich panels without creating thermal bridges. Another significant advancement is CO2 injection technology, which mineralizes captured carbon dioxide within fresh concrete mixes. This process not only reduces the carbon footprint of the concrete but also improves its strength without impacting batching times. On the manufacturing floor, worker safety innovations, like bionic exoskeletons, are being explored to assist with handling heavy precast components, reducing the risk of injury and improving productivity. Retractable enclosures provide controlled environments for concrete curing, preventing defects and ensuring consistent quality regardless of external weather conditions.

Modular Systems and Sustainability: Building for the Future

The future of construction is undeniably modular and sustainable, and innovative precast concrete is at the heart of this change. We are committed to building not just for today, but for generations to come, focusing on green building principles, circular economy models, and superior energy efficiency. Our work, particularly in water control systems and renewable energy, exemplifies this commitment. Holcim, a leading partner for sustainable construction, also highlights the importance of precast and prefabricated solutions for a greener future on their Precast and prefabricated solutions page.

The Power of Modular Precast Construction

Modular precast construction is a game-changer, especially for large-scale infrastructure projects and complex urban developments in busy areas like New York City or the expansive regions of Brazil. By manufacturing structural elements off-site and then assembling them rapidly on location, we open up incredible efficiencies. This off-site fabrication allows for consistent quality control in a factory setting, free from weather delays and site constraints.

Once on-site, these pre-fabricated modules enable rapid assembly, significantly cutting down construction timelines and minimizing on-site labor needs. The scalability and adaptability of modular systems mean they can be custom for anything from commercial complexes to critical infrastructure like bridges and dams. This approach is particularly effective in addressing current building challenges, such as the urgent need for infrastructure upgrades or the rapid deployment of housing solutions. Our patented “French Dam” technology, for instance, uses modular precast elements to dramatically reduce the time and cost associated with building and retrofitting hydroelectric dams and water control systems. You can learn more about these powerful techniques on our Modular Construction Techniques page and see a real-world application in A National Example of Rapid Bridge Construction Using Modular Precast Elements.

How Innovative Precast Concrete Champions Sustainable Construction

Sustainability is not just a buzzword for us; it’s a core principle embedded in our use of innovative precast concrete. We actively champion sustainable construction through several key practices. Our mix designs often incorporate recycled materials like fly ash and slag, which are industrial by-products, reducing the demand for virgin resources and lowering the concrete’s carbon footprint. Factory production also inherently generates less waste compared to traditional cast-in-place methods, as excess materials can be reused or recycled.

Beyond its production, precast concrete contributes significantly to energy-efficient buildings. Its thermal mass properties help regulate indoor temperatures, reducing the need for excessive heating or cooling and thereby lowering energy consumption and costs. This makes it an excellent choice for green building projects, especially for facilities like hydropower plants where long-term operational efficiency is paramount. Furthermore, the inherent durability and longevity of precast concrete minimize maintenance requirements and extend the service life of structures, leading to lower life cycle costs and a reduced environmental impact over time. Our efforts in Dam Rehabilitation Encapsulation demonstrate our commitment to long-term sustainable solutions.

Frequently Asked Questions about Innovative Precast Concrete

How does precast concrete compare to traditional cast-in-place concrete?

This is a question we hear often, and the differences are significant. When we compare innovative precast concrete to traditional cast-in-place methods, several key advantages emerge:

- Quality Control: Precast concrete elements are manufactured in a controlled factory environment. This means consistent mix designs, precise dimensions, and optimal curing conditions, leading to superior quality, greater impermeability, and consistent strength that often exceeds industry standards. Cast-in-place, by contrast, is more susceptible to variations due to on-site conditions, weather, and labor practices.

- Speed: Off-site manufacturing allows for parallel processing – elements are being produced while site work progresses. This dramatically accelerates construction timelines. Once on-site, precast elements are simply assembled, leading to faster completion. Traditional methods involve pouring, curing, and forming on-site, which can be time-consuming and prone to delays.

- Weather Dependency: Factory production is immune to adverse weather, ensuring consistent schedules. Cast-in-place construction is highly dependent on favorable weather, leading to potential delays and cost overruns.

- Site Congestion & Safety: Precast significantly reduces on-site activity, meaning less equipment, fewer workers, and a cleaner, safer job site. Traditional methods often lead to crowded sites, increased traffic, and higher safety risks.

- Cost-Effectiveness: While initial unit costs for precast might sometimes appear higher, the overall project cost is often lower due to reduced construction time, lower labor costs, minimized waste, and improved quality that reduces future maintenance. We explore these savings in more detail on our Why Precast Cost Less page.

What types of projects benefit most from innovative precast?

Innovative precast concrete truly shines in projects that demand speed, precision, quality, and durability. We find it to be the ideal solution for:

- Large-scale Infrastructure: Think bridges, tunnels, highways, and crucially, water control systems and hydroelectric dams. For projects like our patented “French Dam” technology, where rapid deployment and long-term resilience are critical, modular precast is transformative. Examples include major bridge replacements across the U.S. or new hydropower installations in Brazil and Europe.

- High-rise Buildings: In dense urban environments like New York City, precast allows for rapid construction with minimal site disruption, making it perfect for commercial and residential towers.

- Parking Garages: These often feature repetitive elements, making them perfectly suited for the efficiency and cost-effectiveness of precast.

- Projects with Repetitive Elements: Any project where components are replicated, such as certain types of housing, schools, or retaining wall systems, gains immense benefit from the precision and speed of factory production.

- Green Building Projects: Its sustainable attributes, like thermal mass and the ability to incorporate recycled materials, make it a go-to for environmentally conscious developments.

We’ve seen precast used in everything from the Kansas State Innovative Campus to critical civil infrastructure, proving its versatility and efficacy. Our work in Modular Dam Construction is a prime example of how this innovation addresses complex challenges in the renewable energy sector.

What is the future outlook for the precast industry?

The future for innovative precast concrete is incredibly bright, marked by continued growth and exciting technological advancements. We anticipate several key trends shaping the industry:

- Continued Market Growth: With the precast market expected to reach USD $168.17 billion by 2026, the demand for efficient, high-quality, and sustainable construction solutions will only intensify.

- Increased Adoption of Smart Technology: We’ll see even more widespread integration of IoT and sensors for real-time monitoring of structures, enabling predictive maintenance and enhancing longevity. This will be critical for complex infrastructure like dams and bridges, ensuring their performance over decades.

- AI and Machine Learning in Quality Control: Artificial intelligence is already beginning to optimize workflows and detect defects in precast manufacturing, leading to even higher levels of precision and consistency.

- Greater Focus on the Circular Economy: The industry will continue to push boundaries in using recycled materials, developing self-healing concrete, and minimizing waste, contributing significantly to a more sustainable built environment.

- Advanced Digital Fabrication: BIM and digital twin technologies will become even more sophisticated, offering unparalleled design flexibility, error reduction, and project visualization from concept to completion.

Essentially, innovative precast concrete is shaping the future of construction by prioritizing speed, quality, and sustainability. It’s becoming an even more intelligent, versatile, and environmentally responsible solution for the next generation of building challenges. Our commitment to advancing Precast Concrete Technology reflects this exciting outlook.

Conclusion: The Smart Choice for Next-Generation Infrastructure

As we’ve explored, innovative precast concrete is far more than just a building material; it’s a sophisticated construction method that addresses the most pressing demands of modern infrastructure development. We’ve seen how its core advantages—best speed, superior quality, incredible design freedom, and inherent resilience—are reshaping projects across North America, Brazil, and Europe.

From smart concrete embedded with real-time sensors to digital fabrication techniques that eliminate waste and improve precision, the technological advancements in this field are truly transformative. The power of modular precast construction, particularly in addressing complex challenges like those in the renewable energy sector, offers scalable and sustainable solutions. Moreover, its commitment to sustainability, through recycled materials and energy-efficient designs, positions it as a leader in green building practices.

Innovative precast concrete is the smart choice for next-generation infrastructure. It delivers projects faster, builds them stronger, and ensures they are more sustainable for the future. At FDE Hydro, we are proud to be at the forefront of this innovation, utilizing our patented modular precast concrete technology to revolutionize the construction and retrofitting of hydroelectric dams and water control systems. Our solutions offer not just buildings, but intelligent, durable, and environmentally responsible infrastructure that stands the test of time.

We invite you to learn more about our cutting-edge approaches and how we can transform your next project by visiting our page on means and methods.