Why Modern Dam Technology Matters for Critical Infrastructure

Modern dam technology encompasses advanced construction methods, intelligent monitoring systems, and sustainable design practices that are changing how we build and manage these essential structures. Today’s dams integrate innovations like modular construction, digital twins, AI-powered analytics, and eco-friendly materials to deliver safer, faster, and more cost-effective solutions.

Key advances in modern dam technology include:

- Modular and precast construction – Reduces build time by 30-50% compared to traditional methods

- Real-time structural monitoring – Fiber optic sensors, drones, and satellite imagery detect issues early

- Advanced materials – Self-compacting concrete, geotextiles, and composite materials improve durability

- Environmental integration – Fish passage systems and sediment management minimize ecological impact

- Digital systems – AI and digital twins enable predictive maintenance and lifecycle optimization

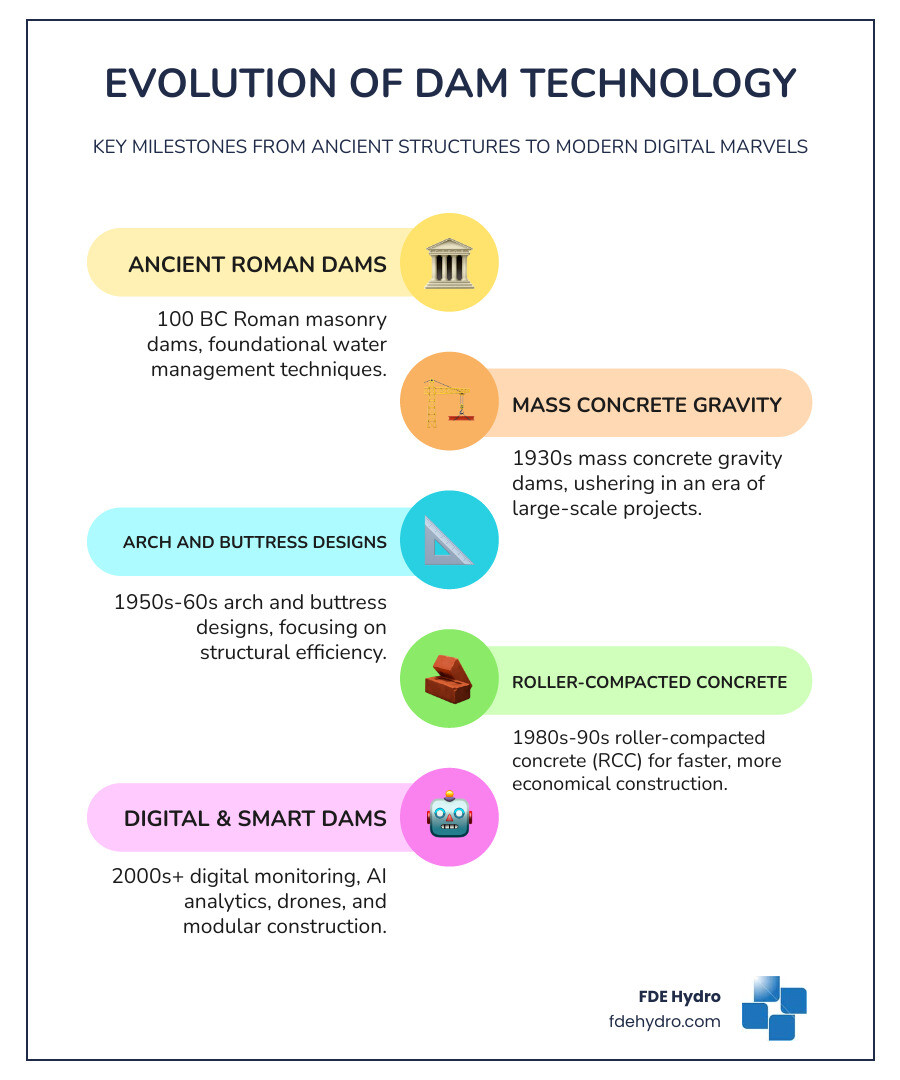

Dams serve as the backbone of modern civilization, providing flood control, enabling irrigation for agriculture, and generating clean hydroelectric power. From ancient Roman water management structures to today’s instrumented megastructures, dam technology has evolved dramatically over millennia.

Yet the industry faces mounting pressure. Aging infrastructure requires rehabilitation. Climate change demands greater resilience. Project costs and timelines spiral using conventional methods. The water infrastructure sector needs innovation now more than ever.

I’m Bill French Sr., Founder and CEO of FDE Hydro™, where we’ve pioneered modular civil construction solutions for the hydropower industry, including patented innovations in modern dam technology that reduce costs and accelerate delivery. My five decades leading major civil construction projects, from Boston’s Logan Airport to the I-93 Fast14 modular bridge initiative, have given me insight into how innovation transforms infrastructure outcomes.

Basic Modern dam technology terms:

From Manual Labor to Megastructures: The Evolution of Construction

For centuries, dam construction was an arduous, labor-intensive undertaking. Imagine the sheer willpower and muscle required to build the massive masonry and earth-fill dams of old. These structures, while impressive for their time, relied heavily on manual labor, basic tools, and locally sourced materials. Construction was slow, often taking decades, and the designs were relatively simple, prioritizing sheer mass and gravity to withstand water pressure.

But just as the world has transformed, so too has the way we build these essential structures. The shift began to accelerate in the 1980s and 1990s, moving away from brute force and towards precision engineering and advanced materials. Today, modern dam technology has completely revolutionized Dam Construction Methods. We’ve transitioned from primarily manual processes to highly mechanized and automated systems, enabling the creation of larger, stronger, and more efficient dams in a fraction of the time. This evolution isn’t just about speed; it’s about safety, sustainability, and economic viability, especially for critical infrastructure projects across North America, Brazil, and Europe.

| Parameter | Historical Dam Construction | Modern Dam Construction |

|---|---|---|

| Materials | Masonry, earth, rock, rudimentary concrete | High-performance concrete, steel, composite materials, geotextiles |

| Construction Speed | Years to decades (e.g., Hoover Dam: 5 years for a massive structure) | Months to a few years for complex structures (e.g., modular systems reduce time by 30-50%) |

| Labor Requirement | Very high, manual labor-intensive | Significantly reduced, highly skilled labor for operation and oversight |

| Safety | Relied on empirical knowledge, prone to unforeseen issues | Data-driven design, advanced monitoring, stringent quality control |

| Environmental Control | Minimal consideration, often significant local impact | Comprehensive environmental impact assessments, mitigation strategies |

Innovations in Concrete and Material Placement

The backbone of many modern dams is concrete, but not just any concrete. Modern dam technology leverages advanced concrete technologies like high-performance concrete (HPC), which offers superior strength, durability, and reduced permeability compared to traditional mixes. This means dams can be built thinner yet stronger, requiring less material overall.

Layered construction methods, often involving roller-compacted concrete (RCC), have also become commonplace. RCC is a drier, stiffer concrete mix placed in layers and compacted by vibratory rollers, similar to asphalt. This technique dramatically speeds up construction, reduces cement content, and lowers costs. For example, projects utilizing these methods in the United States and Canada have seen significant time and cost savings.

At FDE Hydro, we’ve taken this concept even further with our patented modular precast concrete technology, often referred to as “French Dam” technology. This innovation allows large sections of the dam to be manufactured off-site in controlled environments, then transported and assembled rapidly on-site. This approach isn’t just theoretical; it delivers tangible benefits, reducing construction costs and time by 30-50% compared to traditional methods. This efficiency is critical for projects, especially when considering Design and Construction Considerations for Hydraulic Structures in challenging environments or with tight deadlines.

Advanced Materials and Equipment

Beyond high-performance and roller-compacted concrete, the palette of materials available to dam engineers has expanded significantly. Self-compacting concrete (SCC), which flows and consolidates under its own weight without external vibration, simplifies placement in complex forms and tight spaces, improving quality and reducing labor. Composite materials, combining the strengths of different substances, offer innovative solutions for specific structural challenges. Geotextiles, synthetic fabrics, are increasingly used for reinforcement, filtration, and drainage within earth-fill dams, significantly enhancing their stability and longevity.

The equipment used on-site has also undergone a massive change. Gone are the days of rudimentary shovels and wheelbarrows. Today’s construction sites feature fleets of sophisticated machinery: massive excavators, automated concrete batching plants, laser-guided placement systems, and highly efficient cranes. Automated material transfer systems ensure a continuous and precise supply of concrete and other materials, minimizing delays and maximizing efficiency.

This blend of advanced materials and cutting-edge equipment is a hallmark of modern dam technology, allowing us to build bigger, better, and faster across our operational areas in North America, Brazil, and Europe. Our own Precast Concrete Technology is a prime example of how material innovation, combined with smart construction methods, can revolutionize the industry.

Ensuring Longevity and Safety with Modern Dam Technology

The safety and longevity of dams are paramount. These structures hold back immense forces of water, and any failure can have catastrophic consequences for downstream communities and ecosystems. This is why modern dam technology places a heavy emphasis on proactive safety management and data-driven decision-making, particularly as we address the challenges of aging infrastructure across North America and Europe. We’re not just building dams; we’re building resilient, long-lasting assets designed to perform reliably for a century or more. Our approach to Hydropower Asset Management is centered on these principles.

Advanced Monitoring and Structural Health

One of the most significant advancements in modern dam technology is the ability to continuously monitor a dam’s health in real-time. This is achieved through sophisticated Structural Health Monitoring (SHM) systems. Imagine having a dam that can tell you how it’s feeling!

Remote sensing technologies, including satellite imagery and advanced LiDAR scans, provide broad overviews of ground movement and structural deformation. Drones equipped with high-resolution cameras and thermal imaging sensors offer detailed visual inspections of dam faces, spillways, and surrounding areas, reaching places that are otherwise inaccessible or dangerous for human inspectors. This allows us to detect subtle changes or potential issues long before they become critical.

Inside and around the dam, a network of sensors provides crucial data. Fiber optic sensors can detect minute strains and temperature changes within the concrete, indicating stress points. Geotechnical instrumentation, such as piezometers, monitors pore water pressure within the dam’s foundation and embankment, a key indicator of stability. Inclinometers measure subsurface ground movement, helping to identify potential landslides or foundation shifts. All this data is fed into centralized systems, allowing engineers to analyze trends, predict potential problems, and make informed decisions about maintenance and repairs, ensuring the safety of communities in places like New York, California, and Kansas.

The Critical Role of Seepage Control

Ask any dam engineer, and they’ll tell you: seepage is the silent killer of dams. It’s a primary cause of dam failures, slowly eroding foundations, reducing stability, and ultimately compromising the entire structure. The United States Bureau of Reclamation, a leading authority on water resource management, has highlighted this challenge, stating that approximately 70% of dam failures are due to seepage issues. This statistic underscores why effective seepage control is not just important, but absolutely critical for the safety and longevity of any dam, particularly in regions with diverse geological conditions like Brazil.

Modern dam technology tackles seepage with a multi-pronged approach. Grout curtains, formed by injecting cement or chemical grouts into the ground beneath the dam, create an impermeable barrier to block water flow. Seepage barriers, often constructed from impermeable clay or geomembranes, are integrated into the dam’s design. Groundwater management systems, including drainage galleries and relief wells, collect and safely divert any water that does seep through, preventing it from building up pressure or eroding the foundation.

Crucially, real-time data analysis from monitoring systems allows for the early detection of abnormal seepage patterns. If a piezometer detects an unexpected rise in pore water pressure, or if flow meters in drainage galleries show an increase, engineers can investigate and intervene immediately. This proactive approach, enabled by advanced sensors and analytics, is a cornerstone of ensuring the integrity of Water Control Structures and preventing costly and dangerous failures.

Building for the Future: Sustainability and Resilience

As we look to the future, modern dam technology must steer a complex landscape of balancing energy needs with environmental stewardship. Climate change brings increased unpredictability, from more intense floods to prolonged droughts, demanding greater resilience from our infrastructure. Simultaneously, global population growth and economic development are driving increased demands for water and clean energy. This means our dams must be designed not just for today, but for a changing tomorrow, supporting Sustainable Water Infrastructure.

Eco-Friendly Design and Hydropower Optimization

The environmental impact of dams has been a significant concern for decades, particularly regarding river ecosystems and fish migration. Modern dam technology addresses these concerns head-on through eco-friendly design principles and advanced mitigation strategies.

Environmental Impact Assessments (EIAs) are now standard practice, guiding design choices to minimize ecological footprints. A key innovation is the development of effective fish passage solutions, such as fish ladders, elevators, and nature-like bypass channels, which allow migratory fish species to safely steer around dams. Fish-friendly turbine designs reduce mortality rates for fish passing through hydroelectric facilities.

Sediment management is another critical aspect. Dams can trap sediment, impacting downstream river health and reservoir capacity. Modern dam technology incorporates strategies like sediment flushing, bypass tunnels, and sluicing to maintain a more natural sediment flow, preserving downstream habitats and extending the operational life of reservoirs. These integrated approaches are vital for ensuring that hydropower remains a truly sustainable source of clean energy, as detailed in discussions around Hydropower Environmental Impact.

Rehabilitating and Upgrading Existing Dams

Many of the dams in North America and Europe were built decades ago, and while they have served us well, they are now aging infrastructure. The challenges range from structural degradation and outdated components to insufficient capacity for modern flood events or energy demands. This is where modern dam technology offers transformative solutions.

Instead of costly and disruptive full replacements, rehabilitation and upgrading projects leverage new technologies to extend the life and improve the performance of existing dams. This might involve strengthening concrete with advanced materials, installing new spillway gates for improved flood control, or upgrading turbines and generators to improve Hydroelectric Dam Efficiency.

Our modular precast concrete technology at FDE Hydro is particularly well-suited for these rehabilitation projects. We can rapidly and cost-effectively encapsulate existing structures, add new sections, or reinforce critical areas, significantly extending the dam’s operational life and enhancing its capabilities. This approach minimizes downtime, reduces environmental impact, and provides a sustainable solution for maintaining our vital water infrastructure, a process we call Dam Rehabilitation Encapsulation.

The Next Frontier: Emerging Technologies in Dam Engineering

The field of dam engineering is constantly evolving, pushing the boundaries of what’s possible. As we face increasingly complex challenges—from climate change impacts to the need for greater efficiency and sustainability—modern dam technology continues to innovate. The focus is shifting towards risk-informed decision-making, adapting to non-stationary hazards, and using the power of digital tools to create truly smart infrastructure. These advancements represent the cutting edge of Advances in Dam Engineering.

The Digital Revolution: AI, Digital Twins, and Modern Dam Technology

Perhaps the most exciting developments in modern dam technology are happening in the digital field. Artificial Intelligence (AI) and machine learning are changing how we design, build, and operate dams. AI algorithms can process vast amounts of data from structural monitoring systems, weather forecasts, and hydrological models to predict potential issues before they arise. This predictive maintenance capability allows operators to schedule interventions proactively, minimizing risks and maximizing uptime.

Digital twins are another game-changer. A digital twin is a virtual replica of a physical dam, updated in real-time with data from sensors and operational systems. This allows engineers to simulate various scenarios, test different operational strategies, and even predict the impact of future events, all without affecting the physical structure. It’s like having a crystal ball for your dam!

This technology enables comprehensive lifecycle simulation, from initial design through construction, operation, and eventual decommissioning. The growing adoption of digital twins and AI in dam engineering signifies a profound shift, enhancing safety, efficiency, and sustainability across projects in New York City, Lawrence, and beyond. You can learn more about The role of artificial intelligence and digital technologies in dam engineering and how it contributes to AI for Sustainability.

Innovations on the Horizon: The Future of Modern Dam Technology

The future of modern dam technology is incredibly exciting, with several groundbreaking innovations on the horizon:

- 3D Printing of Custom Components: Imagine printing complex dam components, such as intricate spillway gates or specialized turbine parts, directly on-site or in a factory. This could revolutionize customization, reduce waste, and speed up construction for unique project requirements.

- Self-Healing Concrete: Researchers are developing concrete mixes that can automatically repair small cracks, extending the lifespan of structures and reducing maintenance needs. This would be a monumental leap for dam durability.

- Autonomous Construction Equipment: Fully autonomous excavators, dozers, and concrete placers could operate around the clock with minimal human intervention, improving safety, efficiency, and precision on construction sites.

- Modular Dam Construction Techniques: While already a reality with FDE Hydro’s patented “French Dam” technology, the modular approach is ready for even wider adoption. Our system, which uses precast concrete components, significantly reduces construction time and costs, offering a rapid deployment solution for new hydro facilities and critical infrastructure upgrades across North America, Brazil, and Europe. This approach aligns perfectly with the drive for speed, cost reduction, and quality control in large-scale civil engineering projects. Explore more about Modular Dam Construction and its potential.

These innovations promise a future where dams are not only stronger and more efficient but also more adaptive, sustainable, and seamlessly integrated into their environments.

Conclusion

We’ve journeyed through the incredible evolution of dam technology, from the labor-intensive constructions of antiquity to the smart, sustainable megastructures of today. What was once a feat of brute force and rudimentary engineering has transformed into a sophisticated blend of advanced materials, digital intelligence, and environmental consciousness. This leap, driven by modern dam technology, has made our dams safer, more efficient, and better equipped to handle the challenges of a changing world.

The future of hydropower and water management is brighter than ever. With innovations like modular construction, real-time monitoring, AI-powered analytics, and eco-friendly designs, we are building structures that are not only resilient but also in harmony with our planet. Innovators like FDE Hydro are at the forefront of this revolution, pioneering next-generation solutions, such as our patented modular precast concrete technology, to meet global water and energy challenges with unparalleled speed, cost-effectiveness, and quality.

The journey continues, and we are committed to shaping a future where our essential infrastructure is stronger, smarter, and greener for generations to come. We invite you to Explore the future of hydropower and its role in a sustainable world and see how these advancements are making a real difference.